Comprehensive safety detection system and method for wind generating set

A technology for wind turbine safety detection, applied in wind turbines, monitoring of wind turbines, engines, etc., can solve the problems of blade structure damage, susceptibility to noise interference, high skill requirements, etc., achieve damage image visualization, and reduce climbing Operation, guaranteed economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

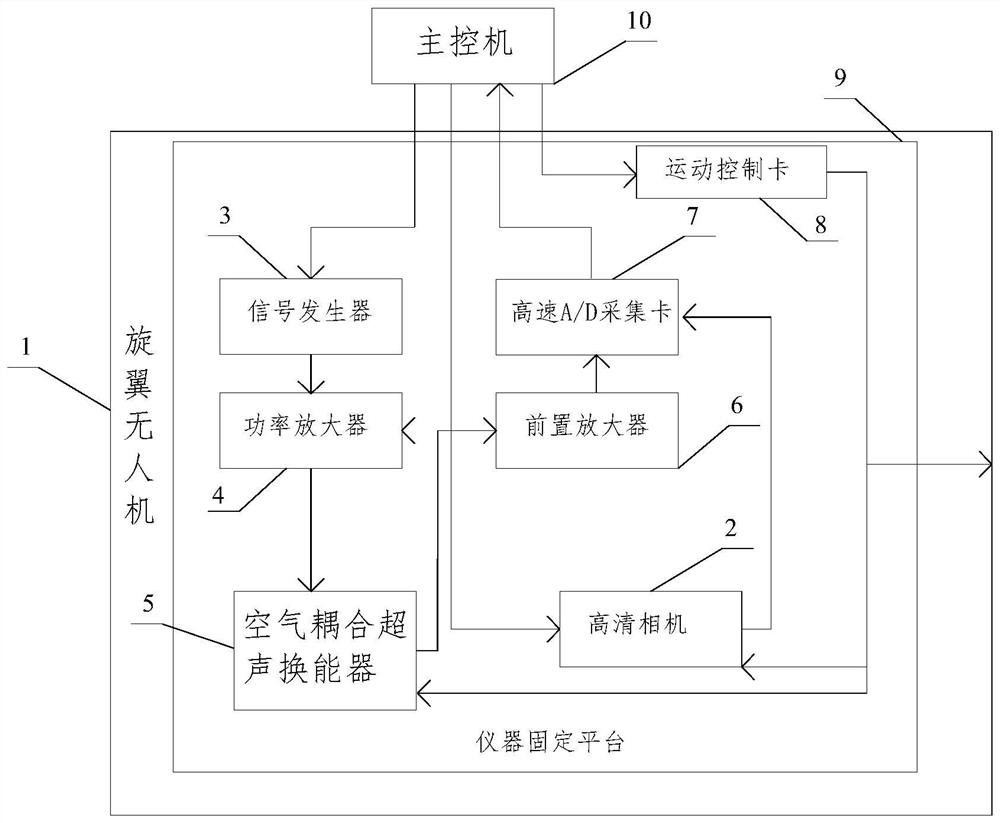

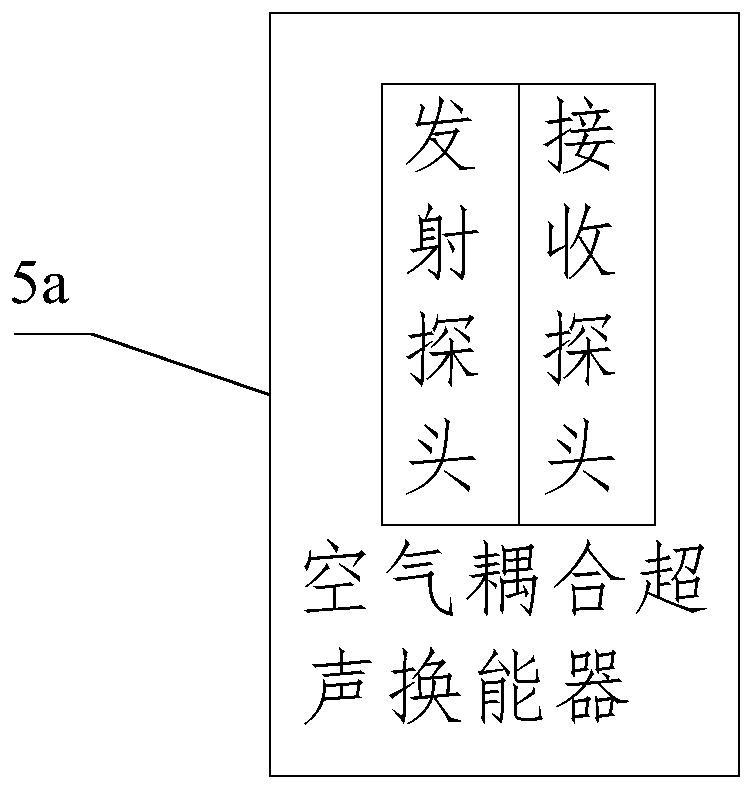

[0026] see Figure 1 to Figure 2 As shown, the comprehensive detection system for wind power generators provided by this embodiment includes a flying device, a camera, an air-coupled ultrasonic detection device, a high-speed A / D acquisition card 7, a motion control card 8 and a main control machine 10; The main control machine 10 communicates with the flight device through the motion control card 8 to control the flight path, and the shooting device, the air-coupled ultrasonic detection device, the high-speed A / D acquisition card 7, and the motion control card 8 are all installed on the flight device. The main control machine 10, the photographing device and the high-speed A / D acquisition card 7 are sequentially connected by communication for photographing and recording the wind power generating set. The main control machine 10, the air-coupled ultrasonic detection device and the high-speed A / D acquisition card The card 7 is sequentially connected by communication, and is used...

Embodiment 2

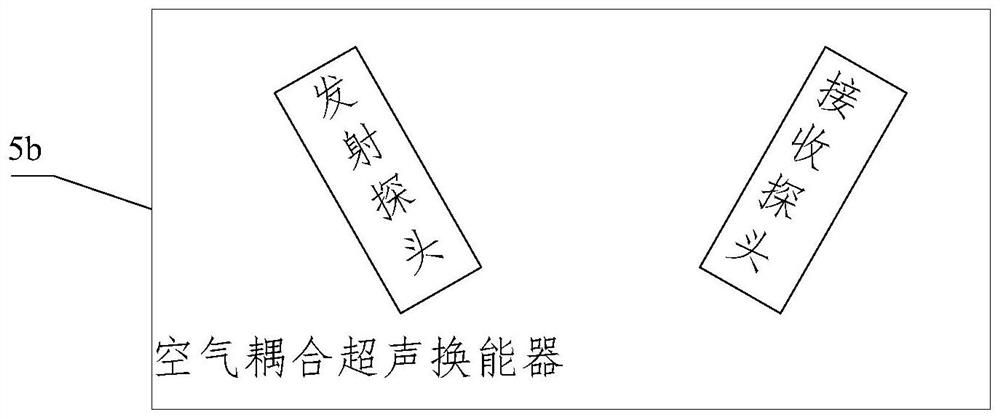

[0030] see image 3 As shown, the difference from Example 1 is that the air-coupled ultrasonic transducer 5 is a double-probe air-coupled ultrasonic transducer 5b, the transmitting probe and the receiving probe are arranged on the same side, and the oblique injection method is used for measurement, which can be adjusted The signal incident angle of the transmitting probe generates longitudinal waves, shear waves, surface waves and guided waves inside the measurement components of the wind turbine to realize in-situ on-line detection.

Embodiment 3

[0032]This embodiment discloses a detection method for a comprehensive detection system of a wind power generating set. The surface structure and internal structure of the wind generating set are scanned synchronously by the photographing device and the air-coupled ultrasonic detection device, and the scanned image of the wind generating set is The information and air-coupled ultrasonic detection signals are transmitted to the main control computer. The main control computer performs image recognition processing on the image information of the wind turbine, extracts feature points for three-dimensional reconstruction, and simultaneously performs ultrasonic scanning display on the air-coupled ultrasonic detection signals. In this way, the surface damage and internal damage of the wind turbine are detected, and finally the safety assessment of each component of the wind turbine is performed according to the damage detection results, and the service life of each component of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com