Steel plate for automobile and production method thereof

A production method and steel plate technology, which is applied in the field of metal material processing, can solve problems such as poor aging resistance, high annealing temperature, and high cooling rate, and achieve the effects of stable BH2, improved product quality, and stable bake hardening value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

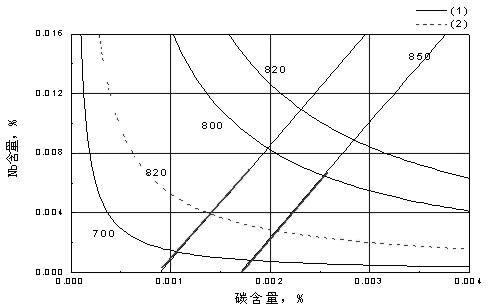

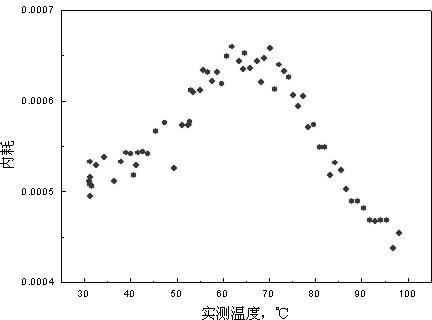

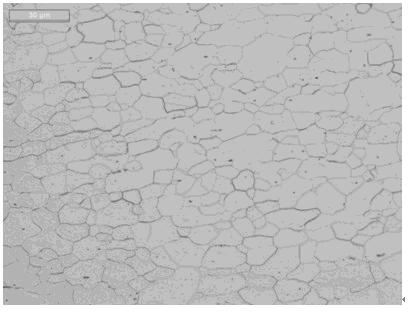

[0034] The present invention provides an embodiment of a steel plate for automobiles and a production method thereof. By optimizing the composition of steel plates for automobiles, adjusting and optimizing the parameters of hot rolling, cold rolling and annealing processes, and the parameters of smoothing processes, a low-temperature annealed ultra-low carbon steel sheet is successfully produced. Bake hardened steel sheet for automobiles. The mass percentage of the chemical composition of the steel for automobile sheet is: 0.0015%≤C≤0.004%, 0.35%≤Mn≤0.65%, Si≤0.03%, 0.03%≤P≤0.05%, S≤0.015%, Als: 0.02- 0.07%, 0.005%≤Nb≤0.015%, 0.0002%≤B≤0.0015%, N≤0.004%, the balance is Fe and other trace elements.

[0035] The embodiment of the present invention also provides a method for producing the steel plate for automobiles comprising:

[0036] Step S1, the molten steel is refined and then continuously cast to obtain a slab. During the refining process, the solid solution carbon conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com