Elevator traction belt and manufacture method thereof

An elevator traction and traction belt technology, applied in belts, textile cables, textiles and papermaking, etc., can solve the problems of poor wear effect, short service life, poor structural design, etc., and achieve long service life and low wear rate. , the effect of traction effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

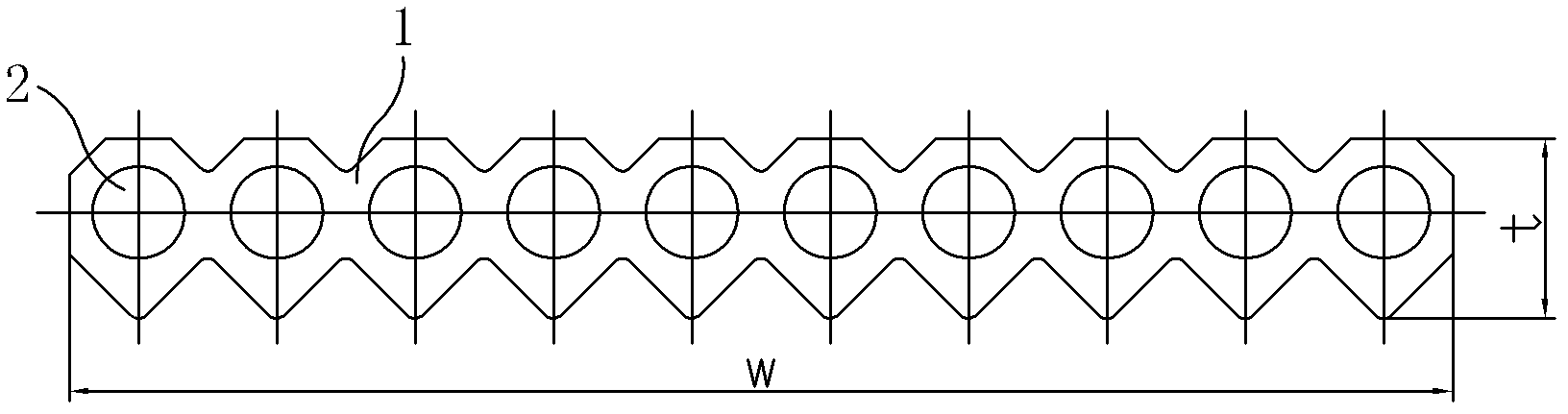

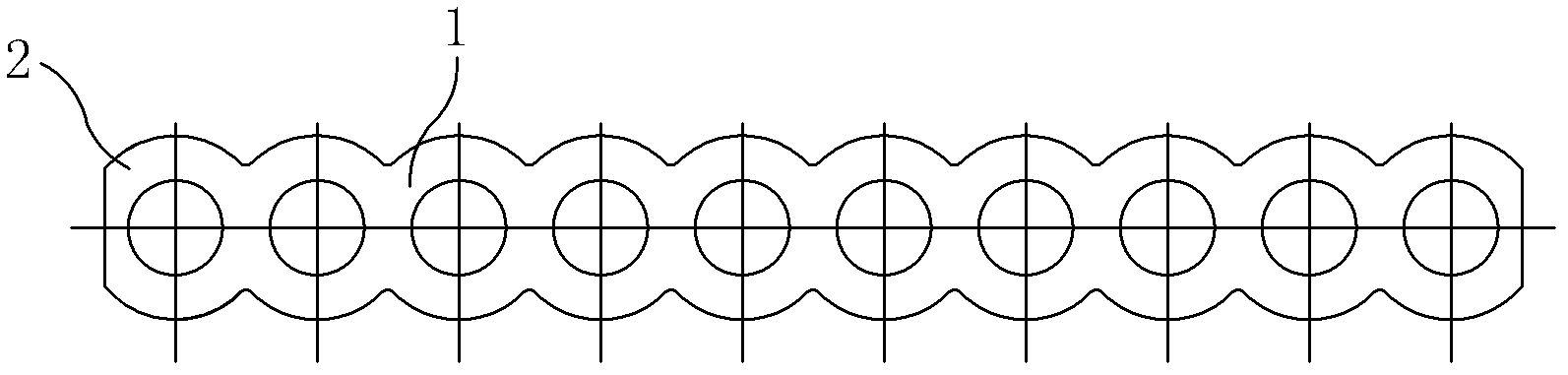

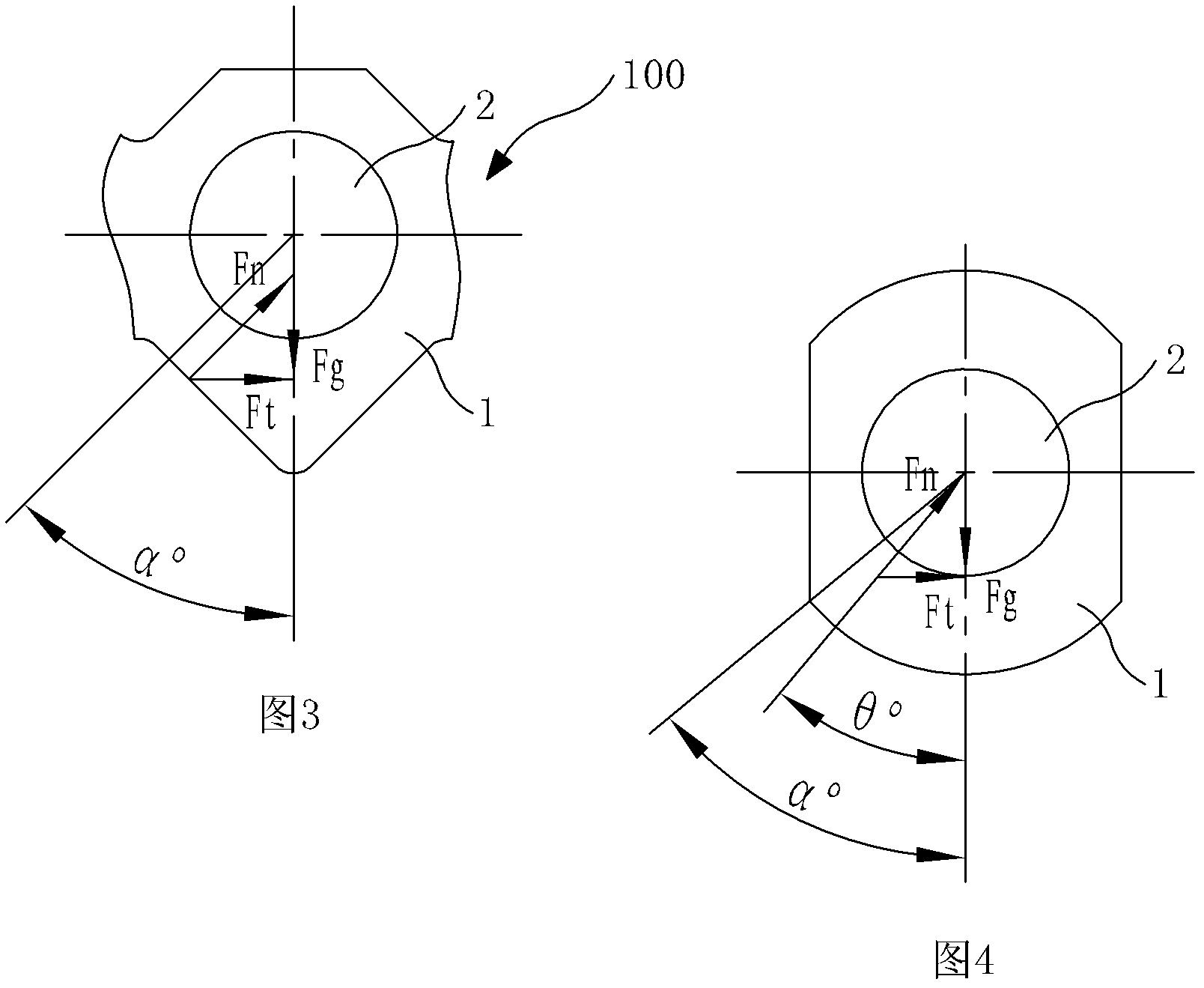

[0024] Embodiments In conjunction with the drawings, the structure and working principle of the present invention will be further described. As shown in 1, the traction belt is provided with multiple load-bearing core wires 2, each load-bearing core wire is made of multiple strands of steel wire, and the outer diameter of the load-bearing core wire is covered with a rubber-plastic coating layer 1. The ratio of the tape thickness t of the rubber-plastic coating to the bandwidth w of the rubber-plastic coating is less than 0.2, and the thickness of the rubber-plastic coating from the outer diameter of the load-bearing core wire to the point of the triangular protrusion is greater than the thickness of the rubber-plastic coating from the outer diameter of the load-bearing core wire to the trapezoidal protrusion. The thickness of the rubber-plastic cladding on the table surface. like image 3 The single body 100 of the traction belt shown in the figure has a load-bearing core wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com