Pipe network pressure control system

A pipe network pressure and control system technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of no discovery, energy consumption, and the inability to guarantee the adjustment accuracy of the outlet pressure of the pressure reducing valve, etc., to achieve reduction Effects of damage and loss, improvement of management, and enhancement of safe and stable operation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

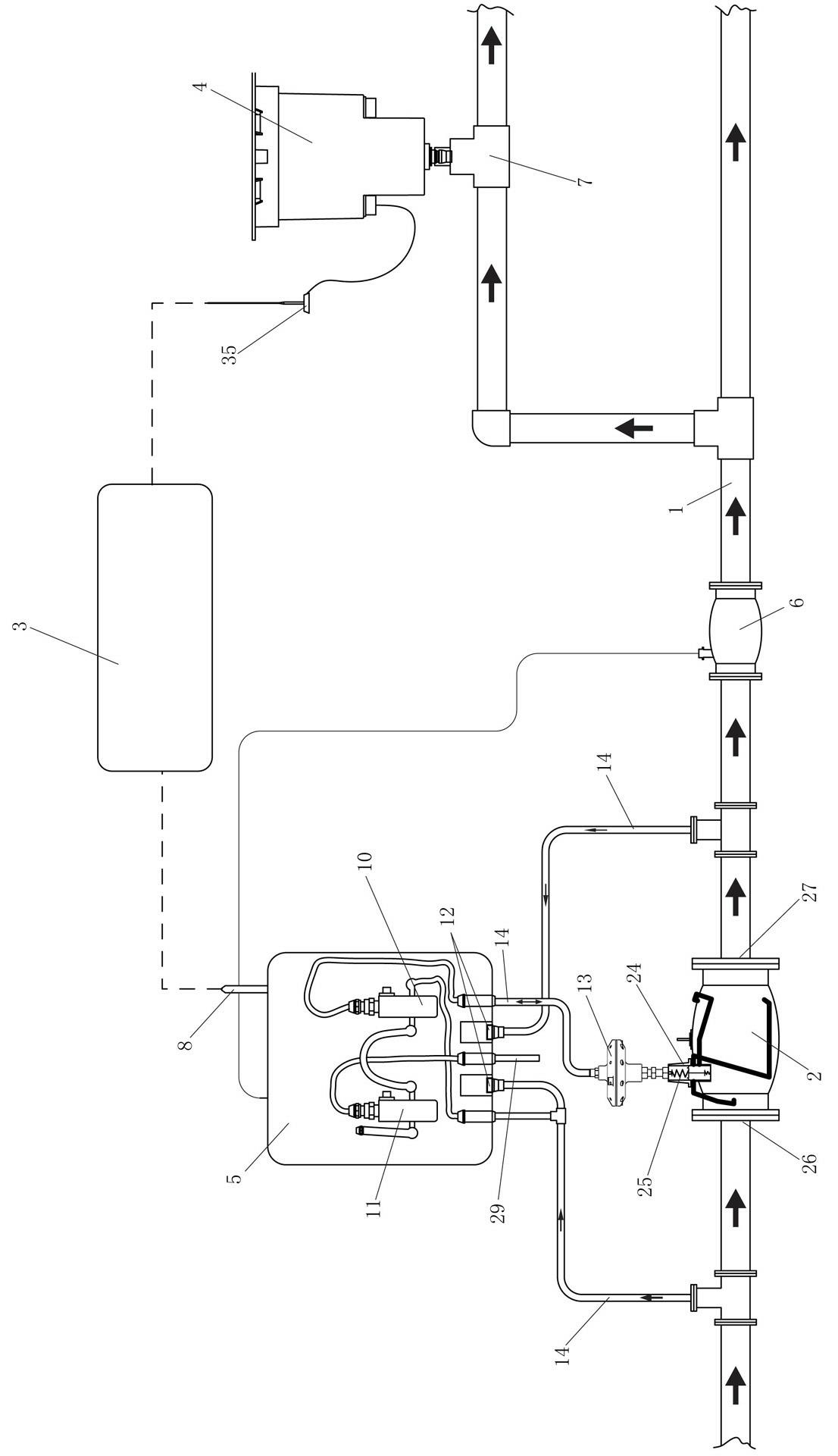

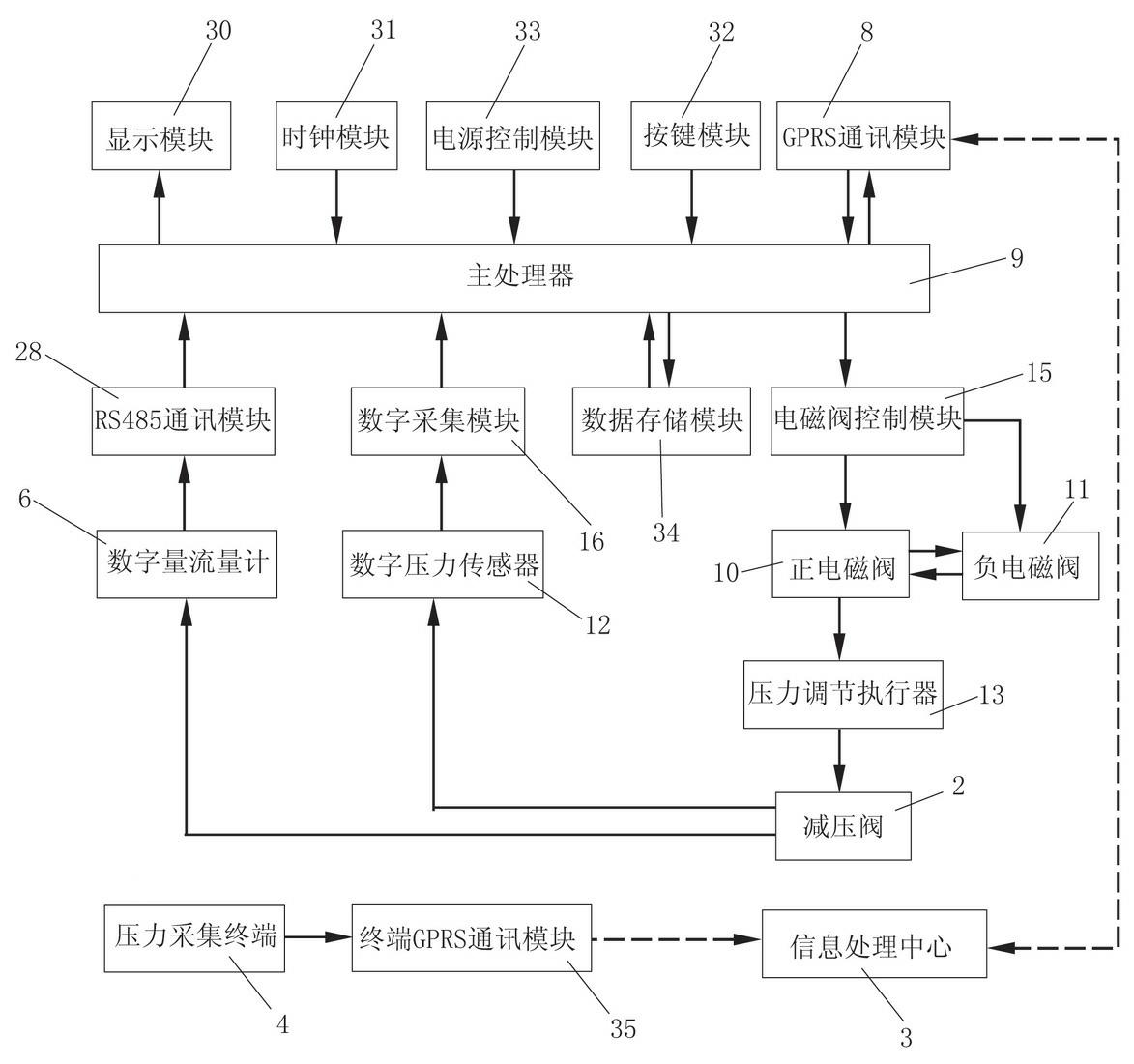

Method used

Image

Examples

Embodiment 1

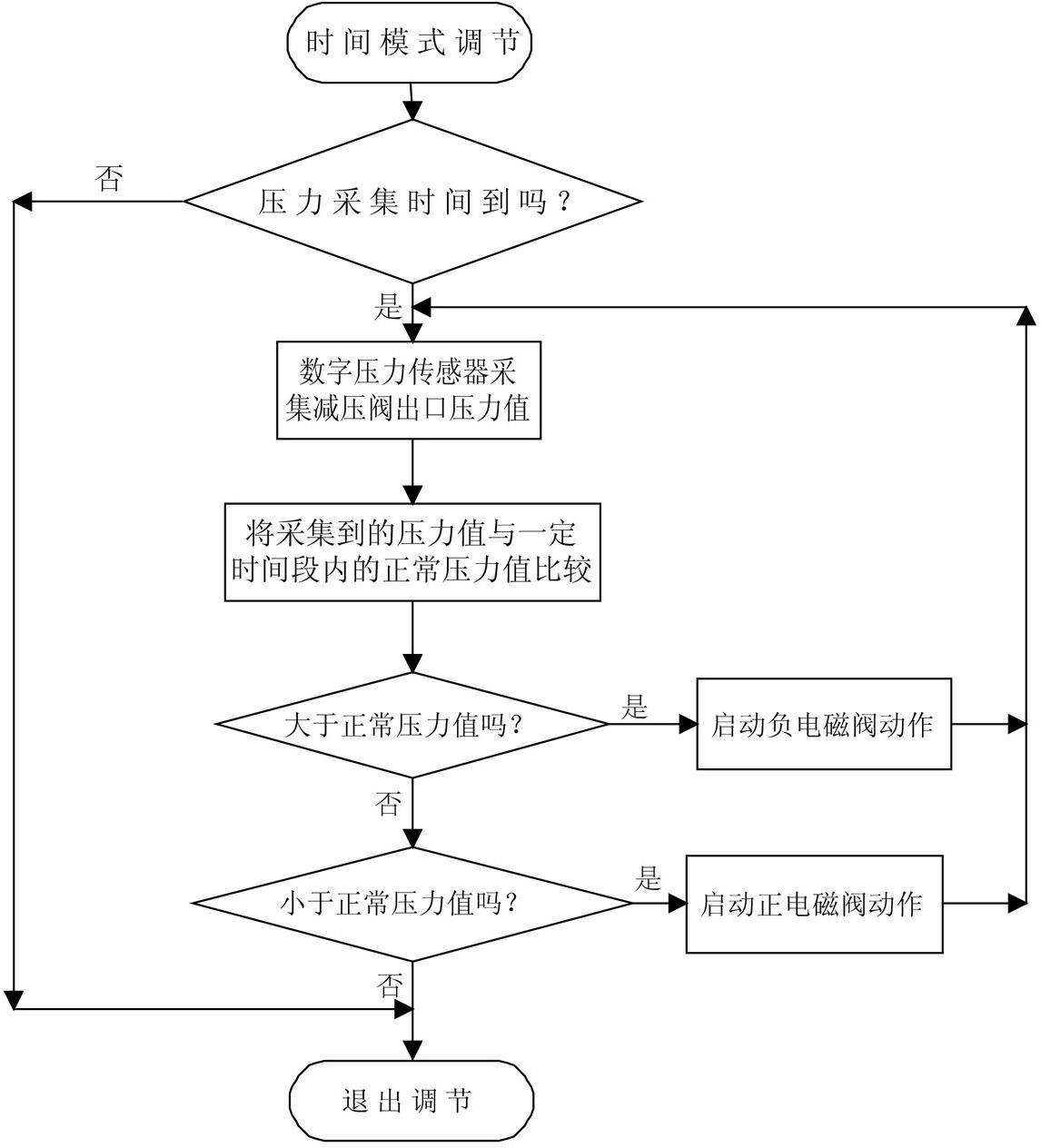

[0035] Embodiment 1: In this example, the control mode of the main processor 9 of the pressure controller 5 adopts the time mode.

[0036] 1) After setting the control mode of the main processor 9 to the time mode through the key module, the main processor 9 sets 7 pairs of normal pressure values within a certain period of time (one time period corresponds to one pressure value, which is regarded as a pair), and a certain period of time The corresponding relationship between the time period and the normal pressure value is: when the time period is 0~7 o’clock (excluding 7 o’clock), the normal pressure value is 0.35Mpa; when the time period is 7~9 o’clock (excluding 9 o’clock), The normal pressure value is 0.5Mpa; when the time period is 9~11 o'clock (excluding 11 o'clock), the normal pressure value is 0.4Mpa; when the time period is 11~13 o'clock (excluding 13 o'clock), the normal pressure value is 0.5Mpa; when the time period is 13~17 o'clock (excluding 17 o'clock), the norma...

Embodiment 2

[0042] Embodiment 2: In this example, the control mode of the main processor 9 of the pressure controller 5 adopts the flow mode.

[0043] A. After the information processing center sets the main processor 9 to the flow mode through the RS485 communication module, the main processor 9 sets 3 to the normal pressure value in a certain flow section, and the corresponding relationship between the certain flow section and the normal pressure value is respectively: When the flow rate is 20~25 cubic meters / hour (excluding 25 cubic meters / hour), the normal pressure value is 0.35Mpa; when the flow rate is 25~30 cubic meters / hour (excluding 30 cubic meters / hour), the normal pressure The value is 0.4Mpa; when the flow rate is 30~35m3 / h (excluding 35m3 / h), the pressure is 0.5Mpa. When setting the flow section, the flow section can be segmented according to the actual situation. For example, take the flow rate of 5 cubic meters per hour to 50 cubic meters per hour as an example, and take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com