Testing system for testing fatigue life of diaphragm capsule bearing alternating pressure

A fatigue life and test system technology, applied in the field of fatigue mechanics test, can solve the problems of high construction cost of the test system, accurate control of the minimum pressure of the unfavorable test, and large space occupied by the test system, so as to reduce the construction cost, the use cost, and the volume. The effect of shrinking, improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

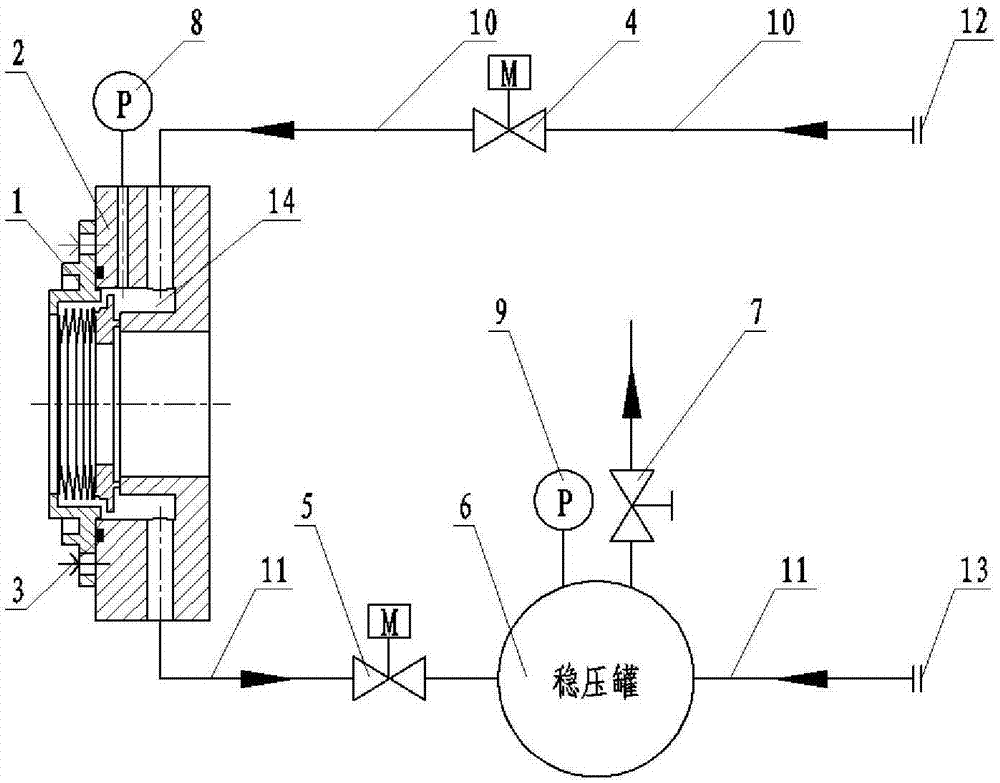

[0016] like figure 1 As shown, a test system for testing the fatigue life of a bellows subjected to alternating pressure, including a bellows assembly mounting seat 2, an O-ring 3, a first solenoid valve 4, a second solenoid valve 5, and a surge tank 6 , exhaust regulating valve 7, first pressure sensor 8, second pressure sensor 9, high pressure pipeline 10, low pressure pipeline 11, high pressure air inlet 12, low pressure air inlet 13 and pressure chamber 14.

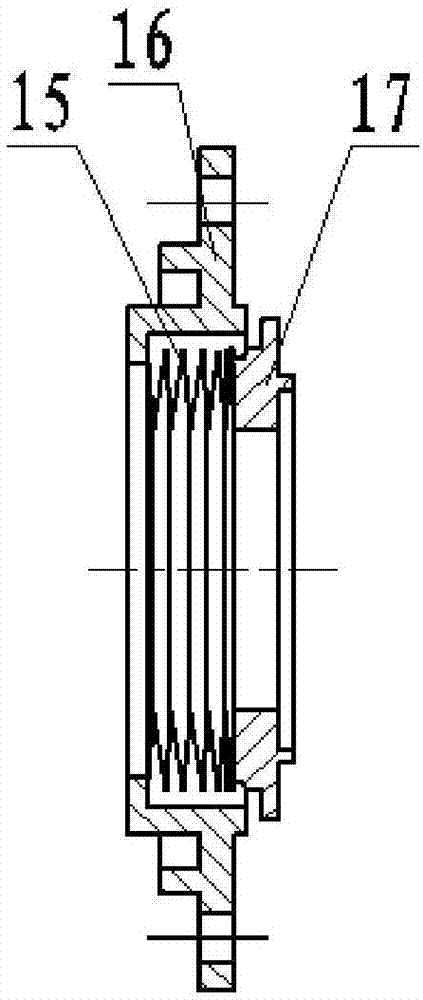

[0017] like figure 2 As shown, the bellows assembly 1 is welded by bellows 15, flange 16, and sealing ring 17. The two ends of bellows 15 are respectively welded with flange 16 and sealing ring 17. After welding, the airtightness inspection is carried out to ensure Welded joints are airtight. The flange 16 includes two parts, one part is an annular shell, and the other is a flange structure located on the outer wall of the annular shell. There are threaded holes on the flange structure. The bellows 15 is located in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap