Friction self-locking rope clip

A cable gripper and self-locking technology, applied in the field of frictional self-locking cable grippers, can solve the problems of high tension, complex structure and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

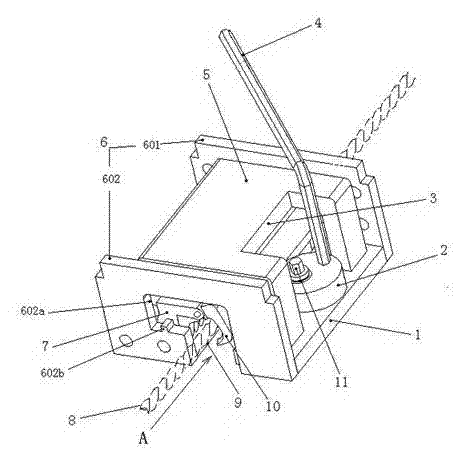

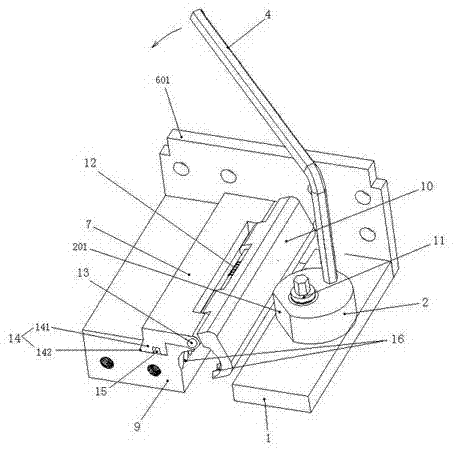

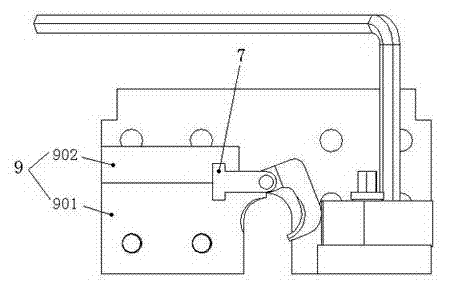

[0015] See figure 1 , figure 2 , the friction self-locking type gripping device, including a base, the base includes a left base 9 and a right base 1, connecting the left and right bases 9, 1 to form an integral connecting plate 6; the connecting plate 6 is divided into upper and lower connecting plates 601 , 602; A through opening A is formed between the left and right bases 9 and 1 bottoms, and the left base 9 along the side of the through opening A direction is provided with a hinge slider 7 sliding in this direction; the hinge slider 7 and the left base 9 are connected by a dovetail rail chute structure 14, the left base 9 is provided with a dovetail groove 14, and the bottom of the hinge slider 7 is provided with a dovetail slide rail 141 to cooperate with the dovetail groove 141 on the left base 9; The dovetail slide rail 141 is provided with a limit hole 15; the hinge slider 7 is hinged with a long pin 13 to have a movable claw tile 10 corresponding to the through ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com