Method and system for detecting whether fastening bolt of roller washing machine is detached or not

A technology of a drum washing machine and a detection system, which is applied to the radio wave measurement system, the measurement device, the re-radiation of sound waves, etc., can solve the problems of complicated and cumbersome calculation, increase the cost, etc., and achieves the improvement of the safety factor, the wide application, and the avoidance of forgetting problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

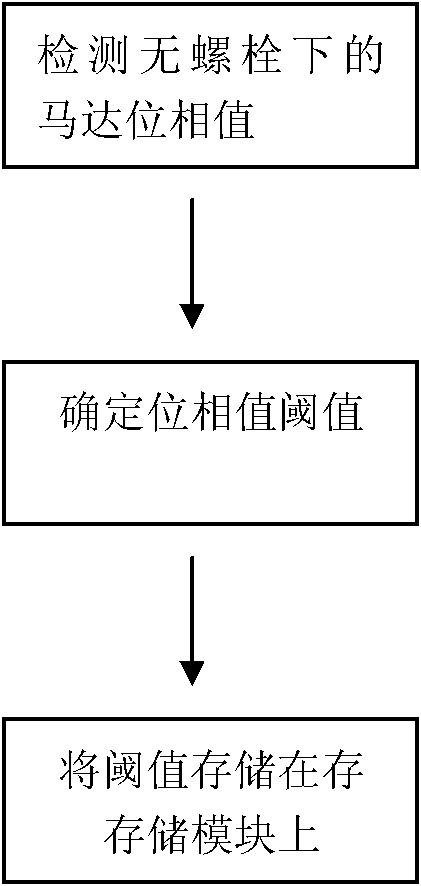

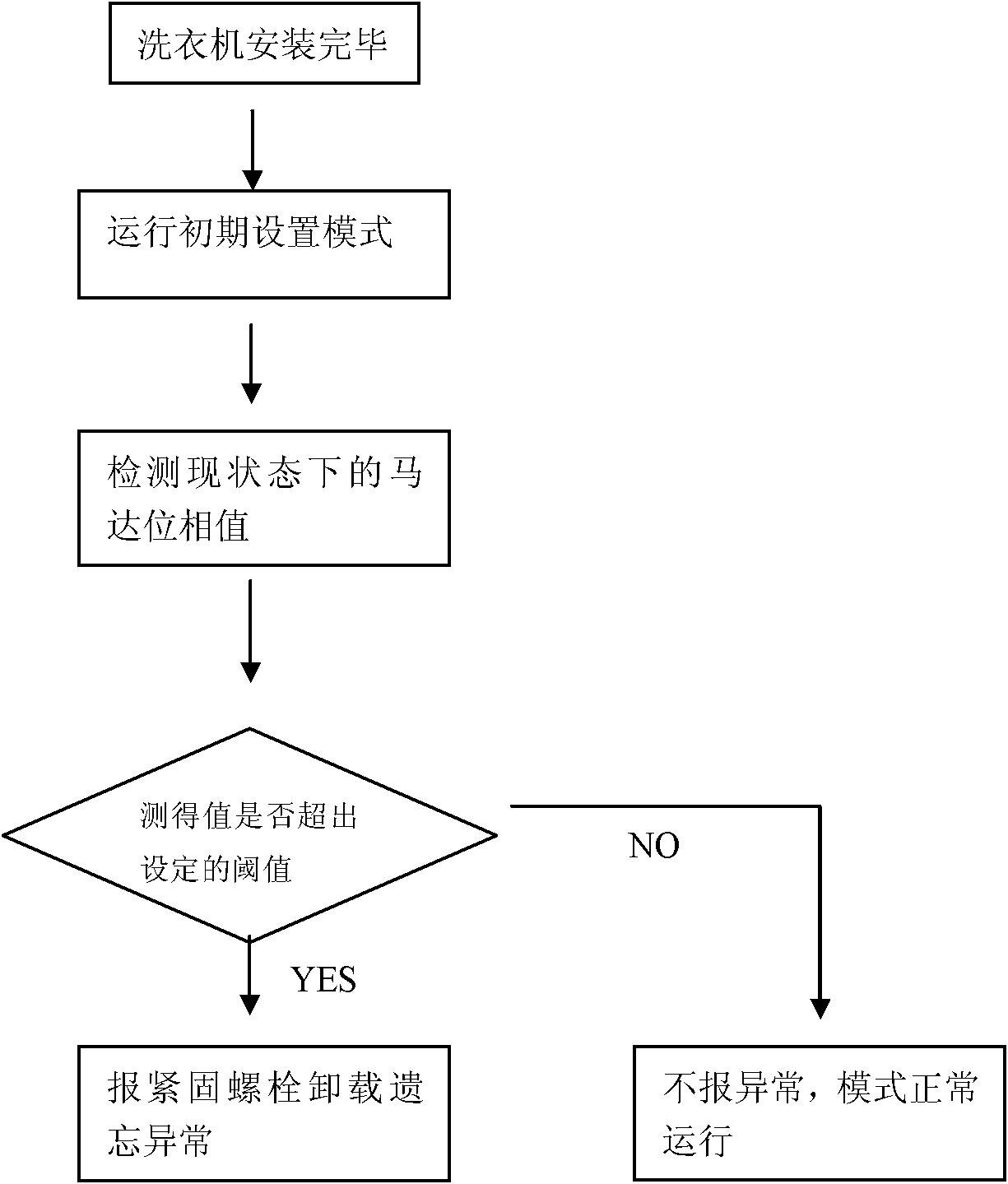

[0028] From Figure 4 In the figure, it can be seen that when the motor increases from low speed to high speed, the change of the passing current is most affected by the tightening bolts. Therefore, during the design, a period of time during which the speed rises is intercepted, and the average value of the current change during this period is measured to determine whether the fastening bolts are removed. Since the change of the current passing through the motor can be reflected by the change of the motor phase value, in the program, the measured motor phase value is used to reflect the current passing through the motor. The motor phase value (duty cycle) refers to the control amount of the motor controlled by the control system when the motor rotates. It changes with the change of the current and can be reflected in RAM-Monitor in real time.

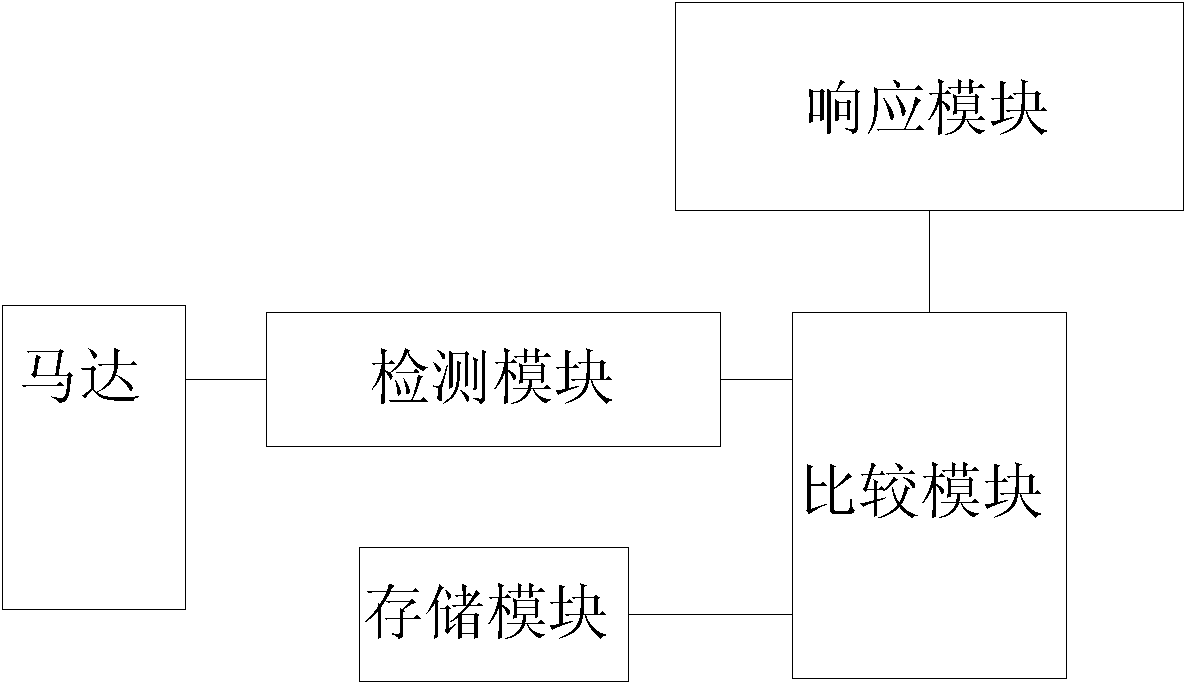

[0029] The detection method of the present invention can adopt various existing detection devices or simple and converted detection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com