Fault eliminating method based on evaluation of detecting points

A detection point and technology to be detected, which is applied in the fault diagnosis of electromechanical products and the field of electrical system troubleshooting, and can solve problems such as difficult fault location, waste, and long troubleshooting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

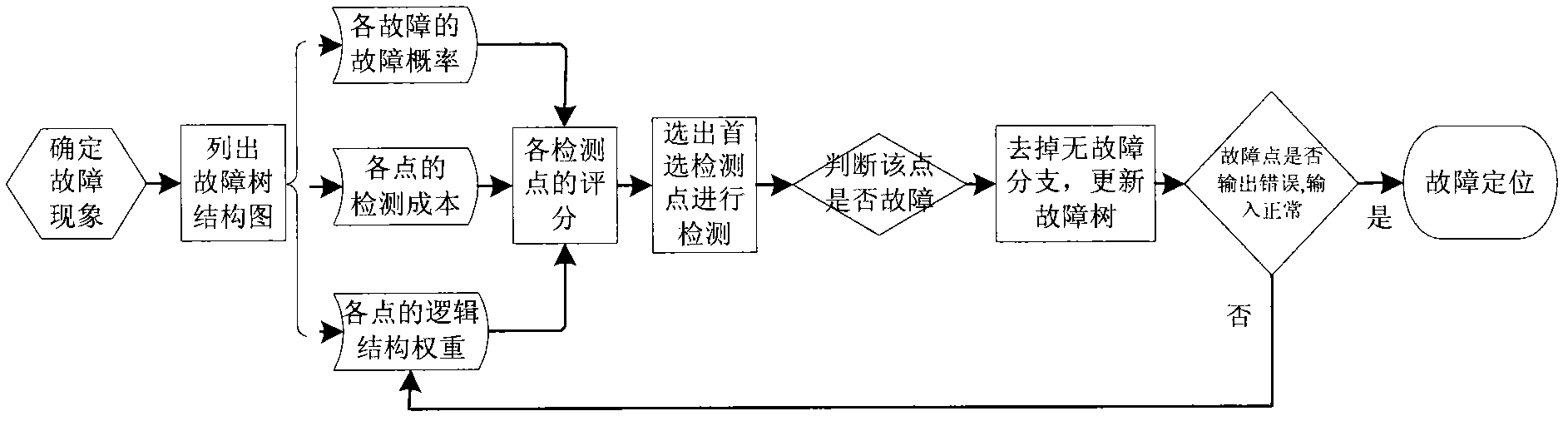

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples. The present invention as figure 1 shown in the following steps:

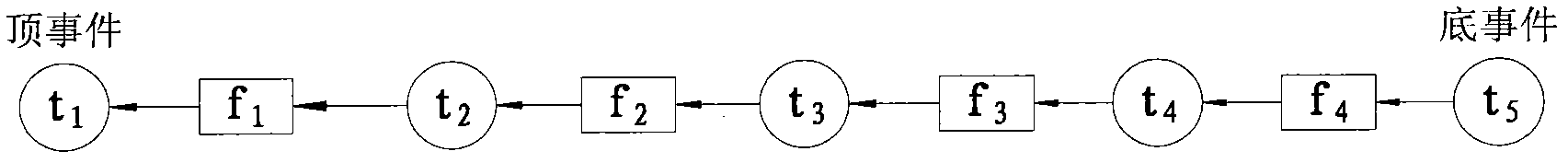

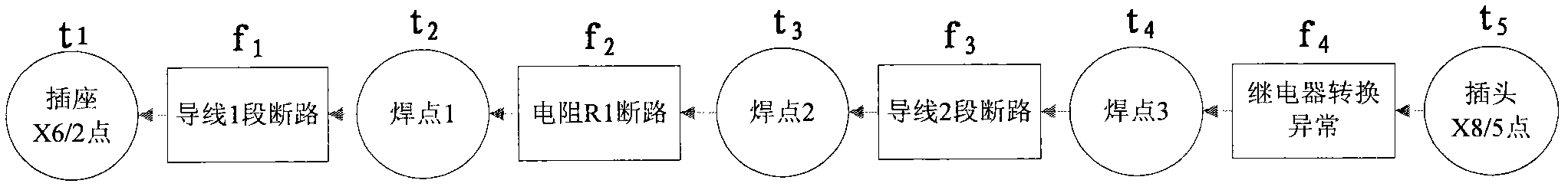

[0044] Take the actual failure ( image 3 ) as an example, during the test of the electrical control box, the test equipment reports a fault, and the fault is that the control voltage 28V is not output. According to the analysis of the cable connection diagram and the wiring diagram of the electrical control box, the output circuit of this control voltage is relatively simple, and the specific circuit is as follows:

[0045] The test equipment is powered through the plug XS8 / 5, after passing through the self-locking relay, and then through a current limiting resistor R1, and finally output to the test equipment through the socket XS6 / 2. Each component is connected by wire welding.

[0046] 1. Determine the fault phenomenon according to the fault of the electromechanical product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com