Hydraulic valve assembly having a cartridge insert valve exhibiting a closing element arranged in a pressure equalized manner

A technology of hydraulic valves, closing bodies, applied in the direction of valve operation/release devices, valve devices, slide valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

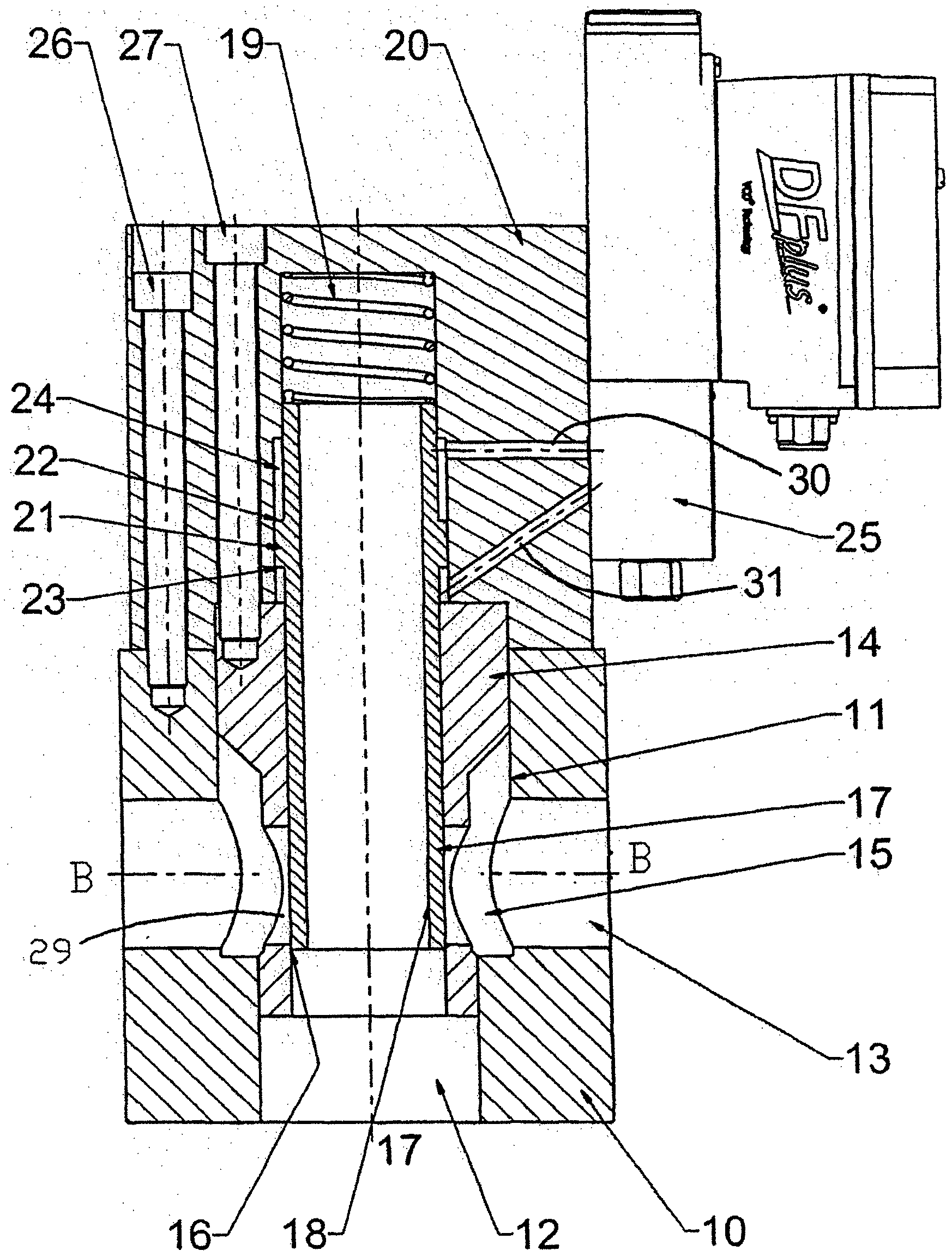

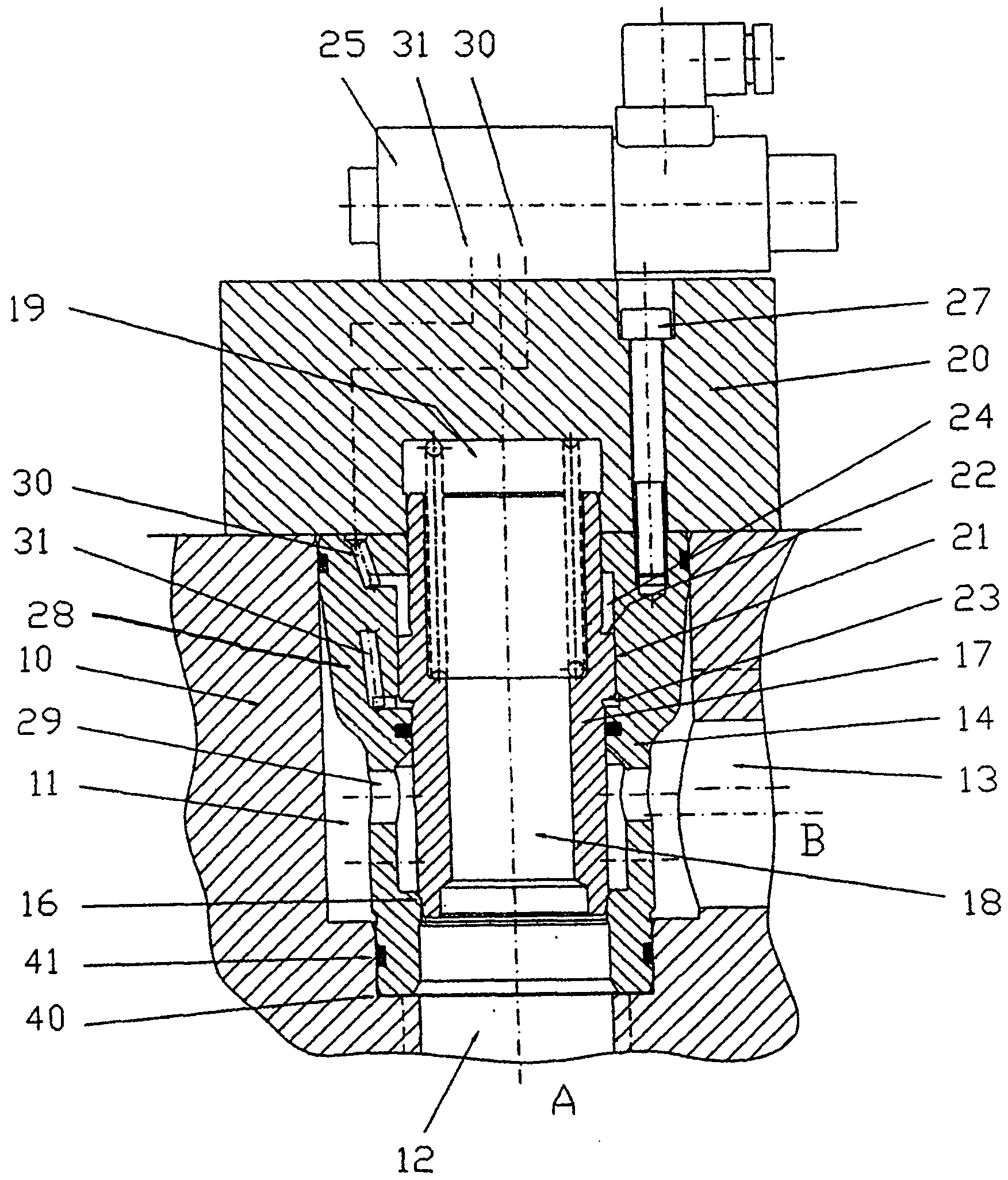

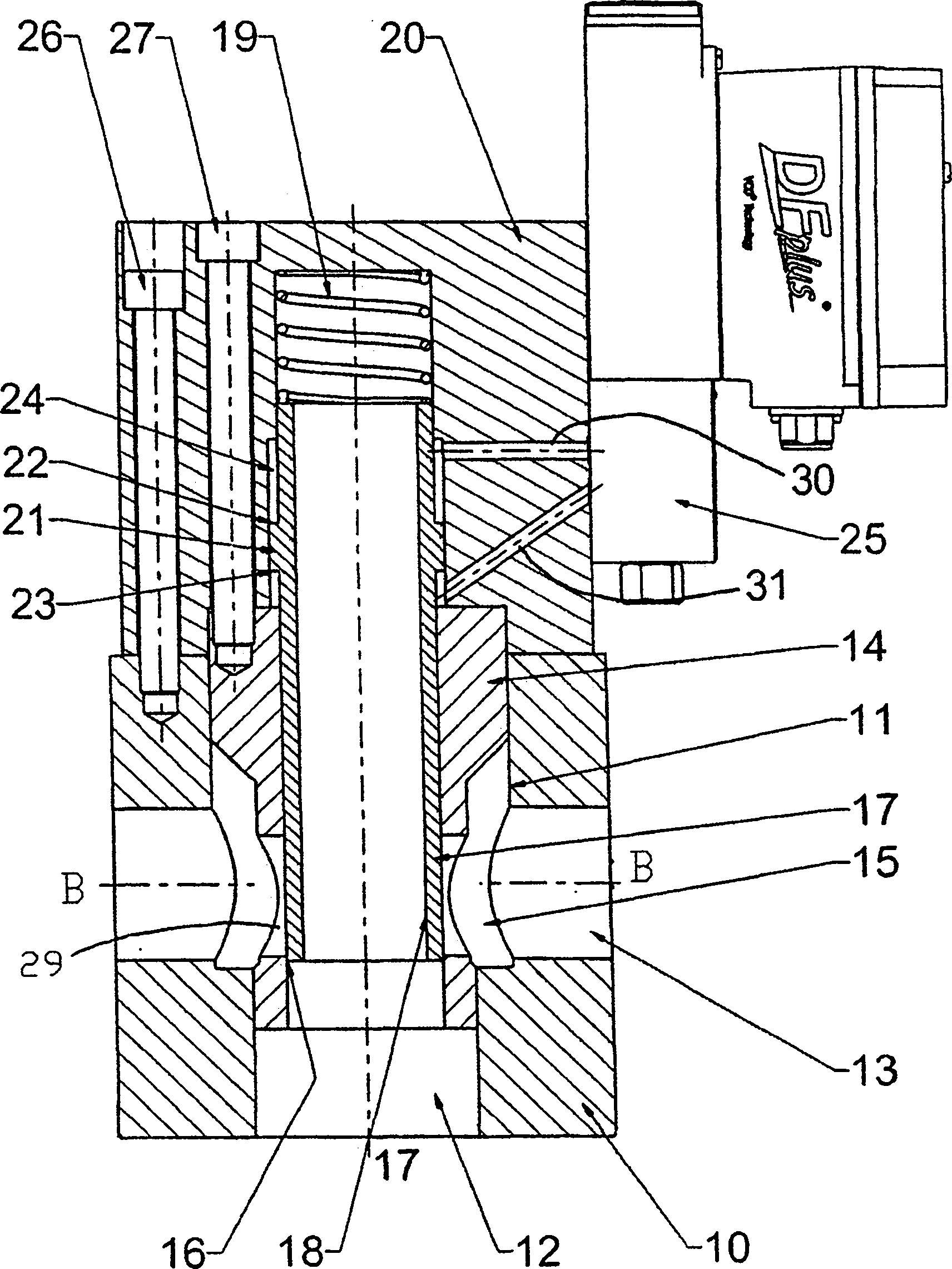

[0022] According to figure 1 In the illustrated embodiment, holes 11 are introduced in the valve block 10 for accommodating the assembly valves which are still to be described. Furthermore, a flow channel 12 (port A) and a flow channel 13 (port B) are arranged in the valve block 10 , which are each connected to the bore 11 in such a way that That is, the connection between the flow channels 12 and 13 can be closed or opened by a fitting valve inserted into the hole 11 . The bore 11 is closed by a valve cover cover 20 which is placed on the valve block 10 and is firmly screwed to the valve block 10 by means of bolts 26 .

[0023] The assembly valve inserted into the bore 11 of the valve block 10 comprises a valve sleeve 14 inserted into the bore 11 and in which the closing body 17 is movable. The valve sleeve 14 has a plurality of openings 29 in the region of the flow channel 13 (port B) leading away from the bore 11 for the hydraulic fluid introduced into the valve block 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com