Manufacturing method of seamless flux-cored wire

A technology of seamless flux-cored welding wire and manufacturing method, which is applied in the direction of manufacturing tools, welding media, welding equipment, etc., and can solve problems such as delamination, uncontinuous production, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

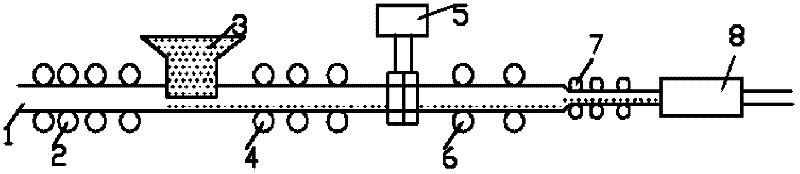

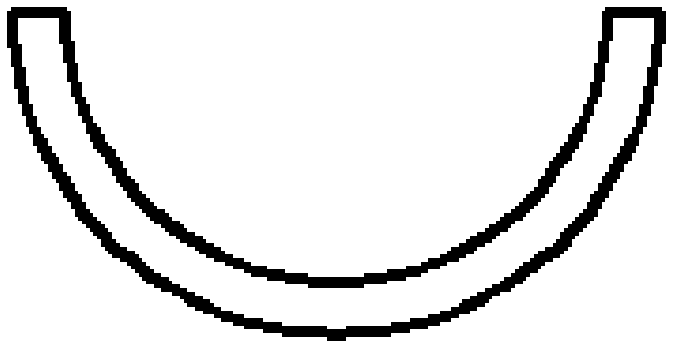

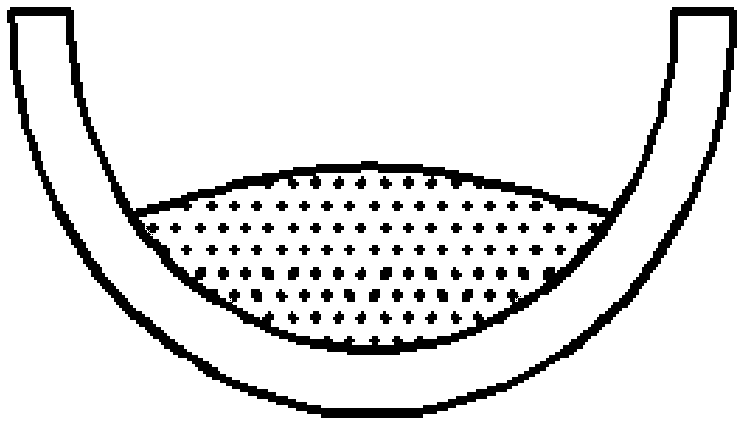

[0029] A method for manufacturing a seamless drug core of the present invention can be realized through the following examples. First roll a low-alloy steel strip with a width of 88mm and a wall thickness of 2.5mm into a "U" shape, and then use a powder adding device to fill a certain proportion of powder into the groove of the steel strip. Then the forming unit rolls the "U" groove into an "O" shape, and welds the steel pipes through high-frequency induction welding. After 12 passes of rolling in a rolling mill, the diameter of the steel pipe is reduced to 10mm. In the annealing furnace, heat the welded pipe to 850°C, then cool the heated welded pipe to 200°C at a speed of 1°C / s, and then water-cool to room temperature and wind up into a coil. This welding wire was drawn to 1.6 mm by a wire drawing machine. After removing oil stains and copper plating, it is closed by a layer winding machine, and then vacuum-packed to form a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com