Zipper conveying and positioning mechanism and top and bottom stop forming device adopting same

The technology of positioning mechanism and zipper is applied in the fields of zipper conveying positioning mechanism and upper and lower stop forming devices, which can solve the problems of high production cost, complex structure, unstable operation of the upper stop injection positioning device, etc. wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

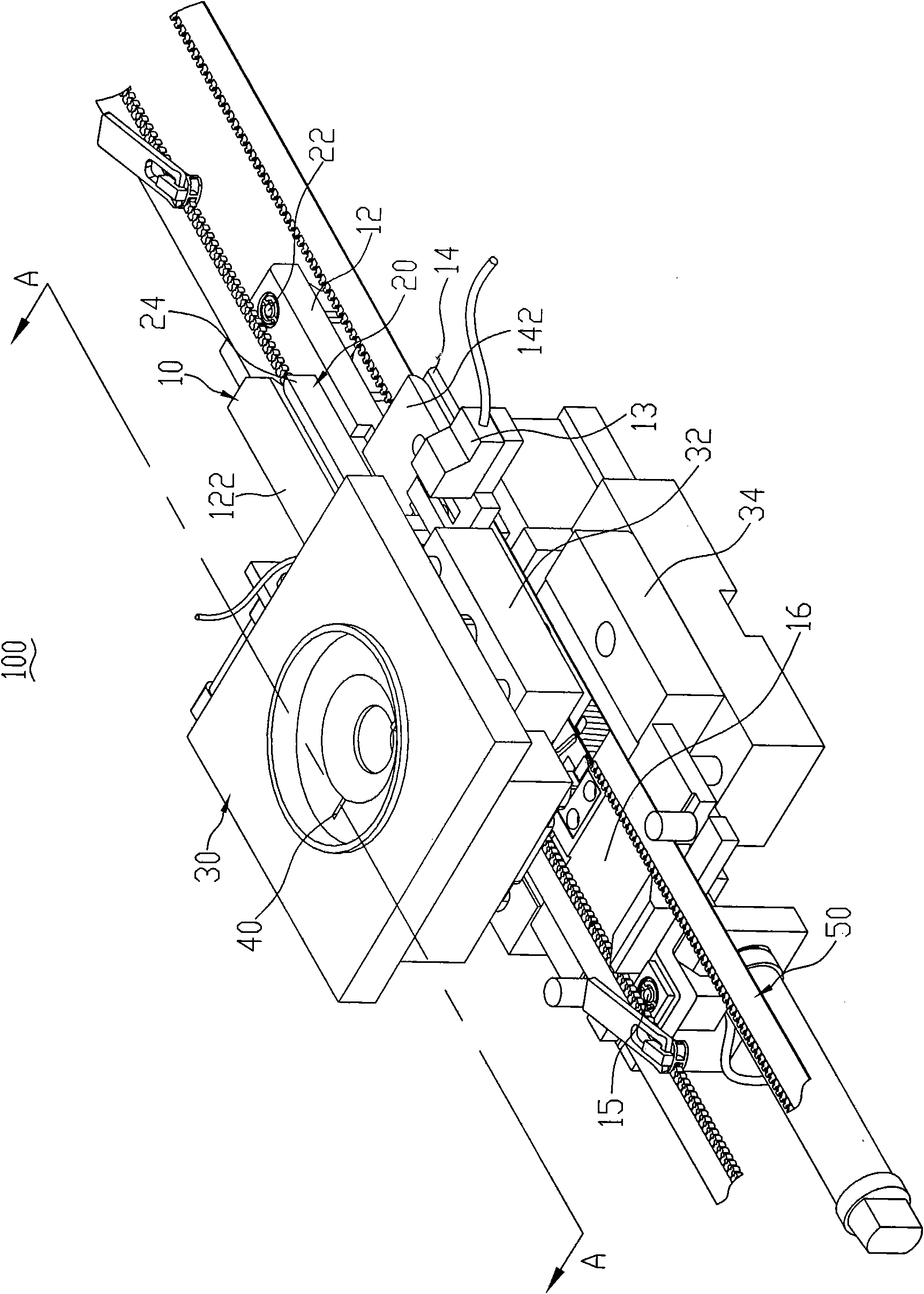

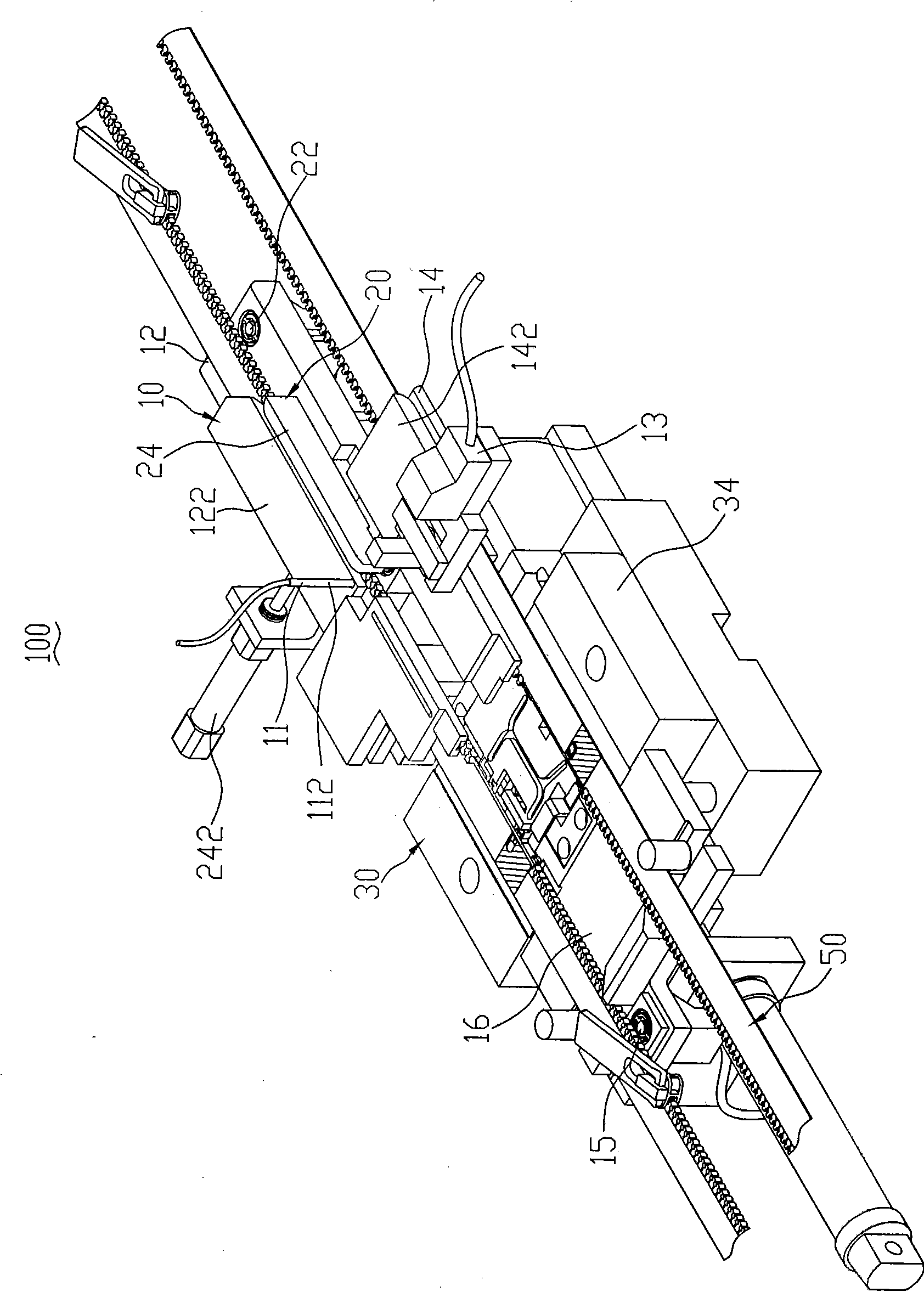

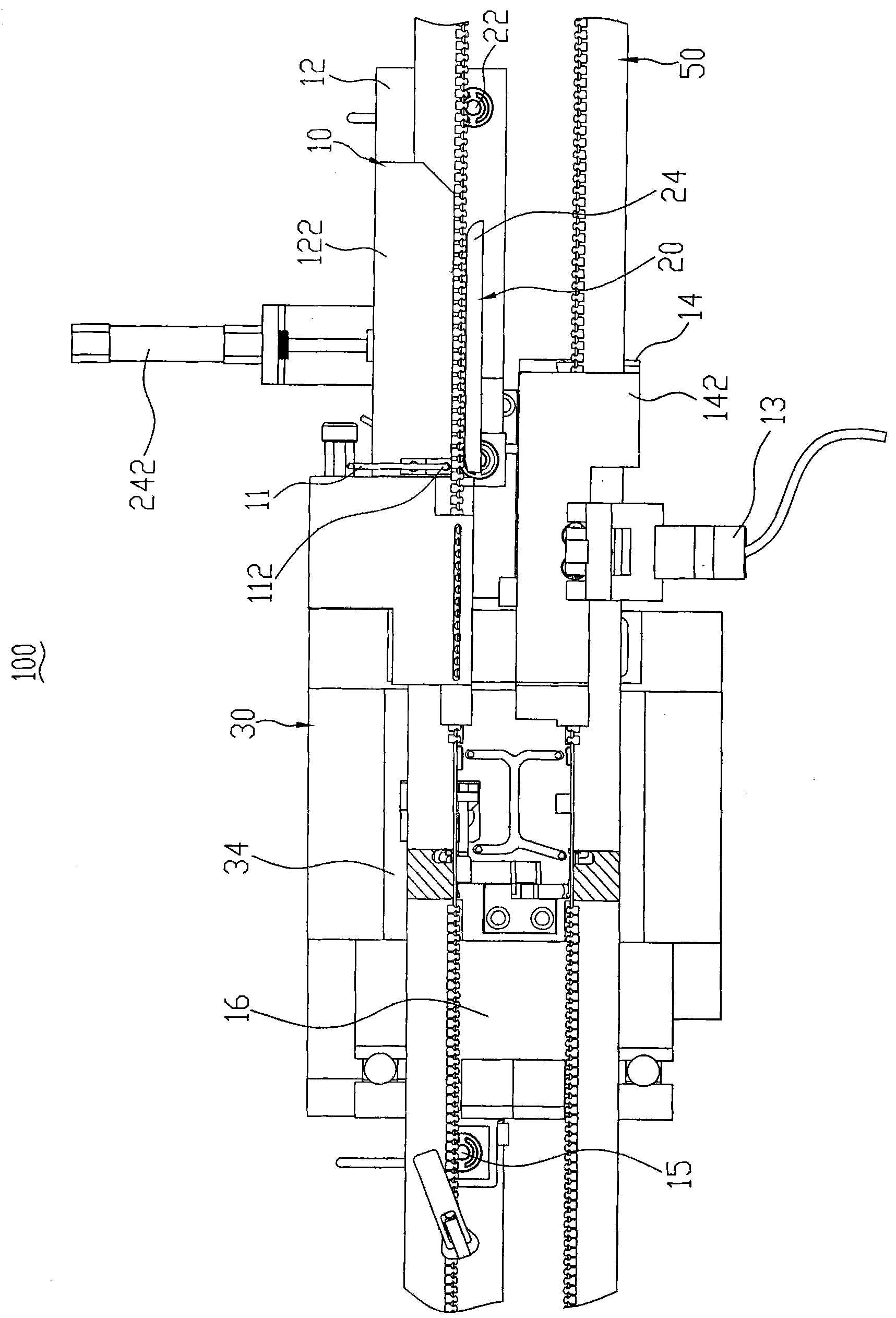

Image

Examples

Embodiment Construction

[0036] Please refer to Figure 9 , which is shown as a perspective view of the open zipper chain 50 to be processed in the present invention. There are several segments of chain teeth 56 , and the distances between each segment of chain teeth 56 are equal to each other to form a plurality of blank segments 58 . Each blank section 58 of the two chain belts 52, 54 is respectively provided with a punching hole 51 close to the bottom stop position, and the two punching holes 51 are respectively close to the cloth ribs 53 of the two chain belts 52, 54, and the cloth is not cut off. Tendon53. The upper and lower stops (not shown) of the long zipper chain 50 are respectively formed on the two ends of the blank section 58 . One end of the bottom stop (not shown) of the zipper chain 50 is adjacent to the fastener element 56 , and the other end extends into the punching hole 51 . Each chain element 56 of the left chain belt 52 is threaded with a slider 55 .

[0037] Please refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com