Electric railway damping automatic passing neutral section system

An automatic over-phase, electrified railway technology, applied in power lines, railway vehicles, motor vehicles, etc., can solve the problems affecting the safety and stability of the traction system and locomotives, reducing the speed and efficiency of trains, and damage to the power supply system and locomotives. Achieve the effect of avoiding the influence of the traction system and the electrical equipment of the locomotive, reducing the adverse influence and weakening the transient overvoltage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

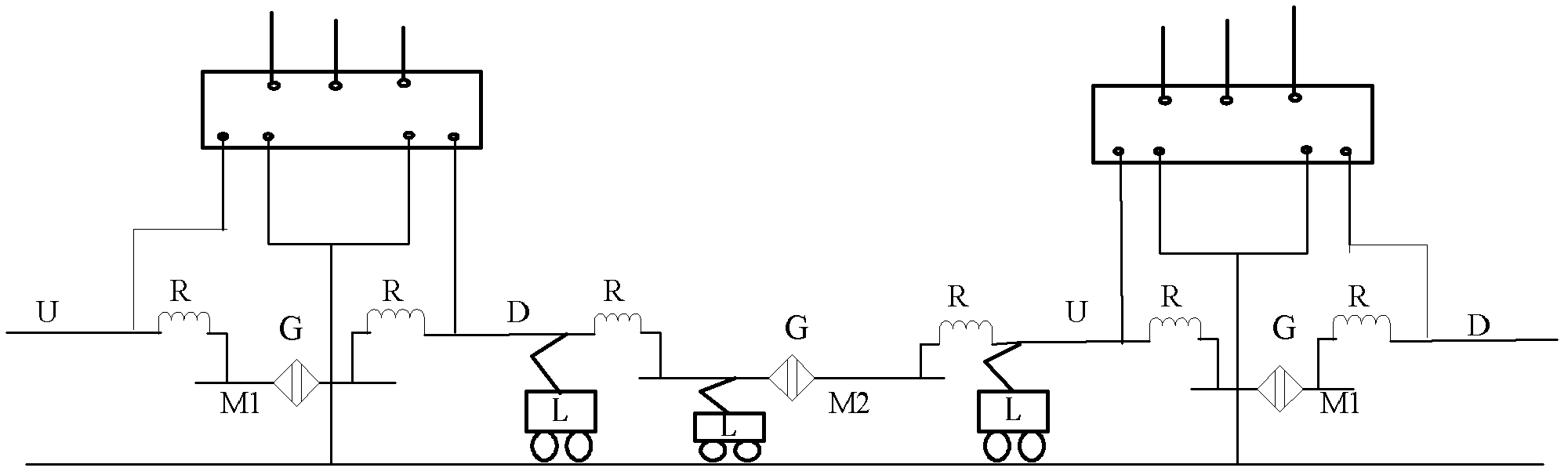

[0019] figure 1 Shown, a kind of specific embodiment of the present invention is:

[0020] An electrified railway damping automatic over-phase separation system, which is composed of: a high-voltage large-capacity resistor R is connected in series between the power supply arms U and D of the traction substation and the catenary neutral section M1 at the exit of the traction substation; A high-voltage large-capacity resistor R is also connected in series between the power supply arms U, D of the power station and the catenary neutral section M2 between the two traction substations; the catenary neutral section M1 at the exit of the traction substation and two Phase-separated insulating elements G are also connected in series in the middle of the catenary neutral section M2 between the traction substations.

[0021] The rated voltage of the high-voltage large-capacity resistor R in this example is 27.5kV, and the capacity is 2-4MW. The resistor R is a non-inductive resistor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com