Acrylic resin and preparation method thereof and paint comprising acrylic resin

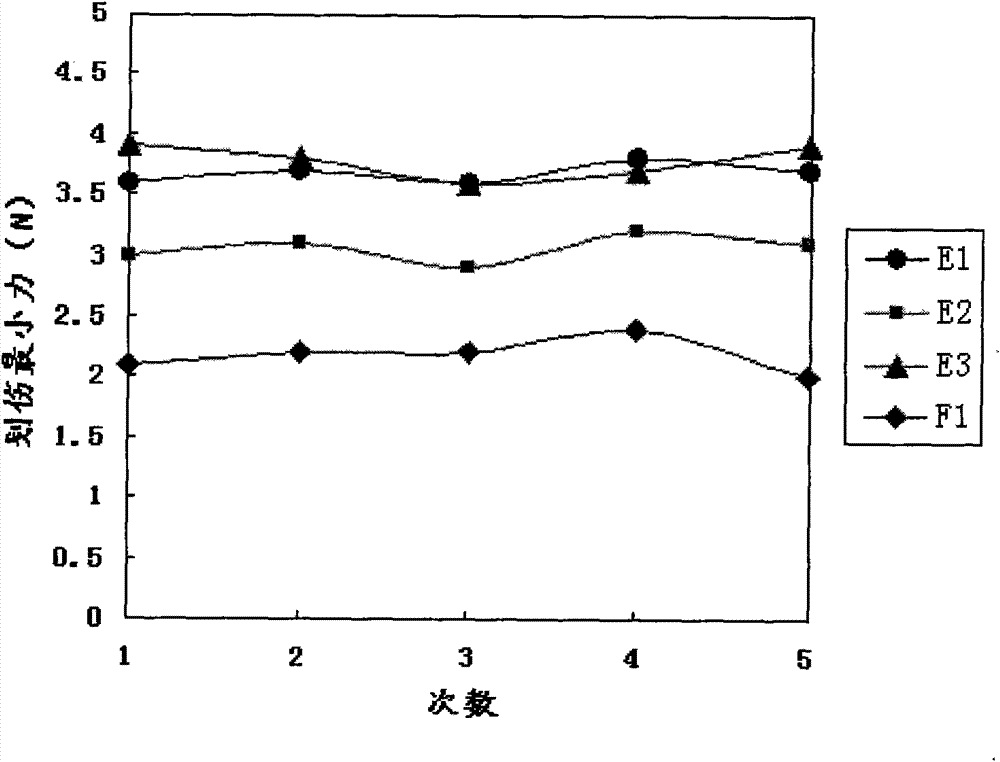

A technology of acrylic resin and acrylic acid, applied in the direction of coating, etc., can solve the problems of poor scratch resistance and achieve the effect of improving scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing acrylic acid, the method comprising: polymerizing monomer 1, monomer 2, monomer 3, and monomer 4 under the action of an initiator to obtain an acrylic resin;

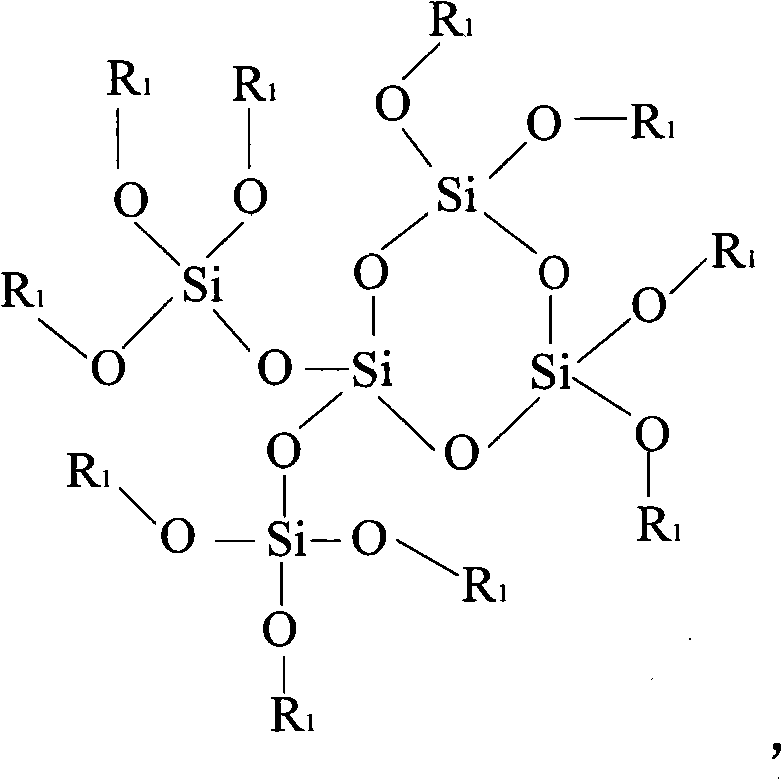

[0038] Among them, monomer 1 is

[0039]

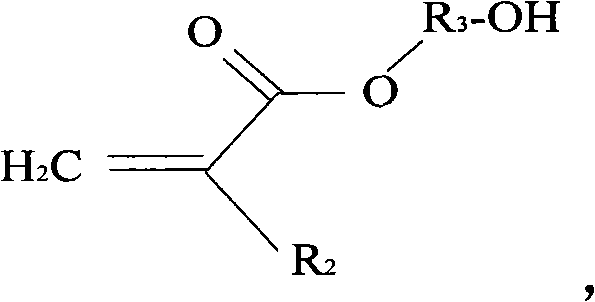

[0040] Monomer 2 is

[0041]

[0042] Monomer 3 is

[0043]

[0044] Monomer 4 is

[0045]

[0046] Among them, R 1 for R 2 , R 4 , R 5 and R 6 is hydrogen or alkyl, R 3 , R 7 For the alkyl.

[0047] According to the preparation method of the acrylic resin provided by the present invention, the initiator is an azo initiator and / or an organic peroxy initiator. More preferably, the initiator is azobisisobutyronitrile and / or benzoyl peroxide.

[0048] According to the preparation method of acrylic resin provided by the present invention, the method may further comprise the steps:

[0049] (1) Mix monomer 1, monomer 2, monomer 3, monomer 4 and initiator uniformly to obtain a mixed solution; ...

Embodiment 1

[0069] 1. Synthesis of Monomer 1

[0070] The device is equipped with a heating device, a heating and heat preservation device, and a dripping device. Add 31.5g of water and 143.5g of ethanol to the container, adjust the pH value to 3.5 with hydrochloric acid, and the temperature is 25°C. Add 51g of ethyl orthosilicate, stir and hydrolyze for about 0.5h; then drop 62g of γ-methacryloxy-propyl-trimethoxysilane into the above liquid within 2h through the dripping device, and continue to keep warm for about Discharge after 5.5h. Stir and heat throughout. The transparent monomer 1 was obtained.

[0071] 2. Synthesis of acrylic resin

[0072] The synthetic formula of acrylic resin is shown in Table 1.

[0073] Table 1

[0074]

[0075] The device is equipped with a stirring device, a condensation reflux device, a heating and heat preservation device, and a dripping device. Add component 1 to the container and heat to 80°C; add component 2 to the container within 3 hours w...

Embodiment 2

[0077] Monomer 1 The monomer 1 synthesized in Example 1 was used.

[0078] The synthetic formula of modified acrylic resin is shown in Table 2.

[0079] Table 2

[0080]

[0081]

[0082] The synthesis process was the same as in Example 1 to obtain acrylic resin A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com