Polymer hollow microspheres, preparation method thereof and preparation method for coating inorganic mineral matters by utilizing polymer hollow microspheres

A technology for polymer and hollow microspheres, applied in the field of preparation of polymer hollow microspheres, can solve the problems of high pollution, small rigidity modulus, collapse, etc., and achieve the effects of safe preparation process, improved environmental protection, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

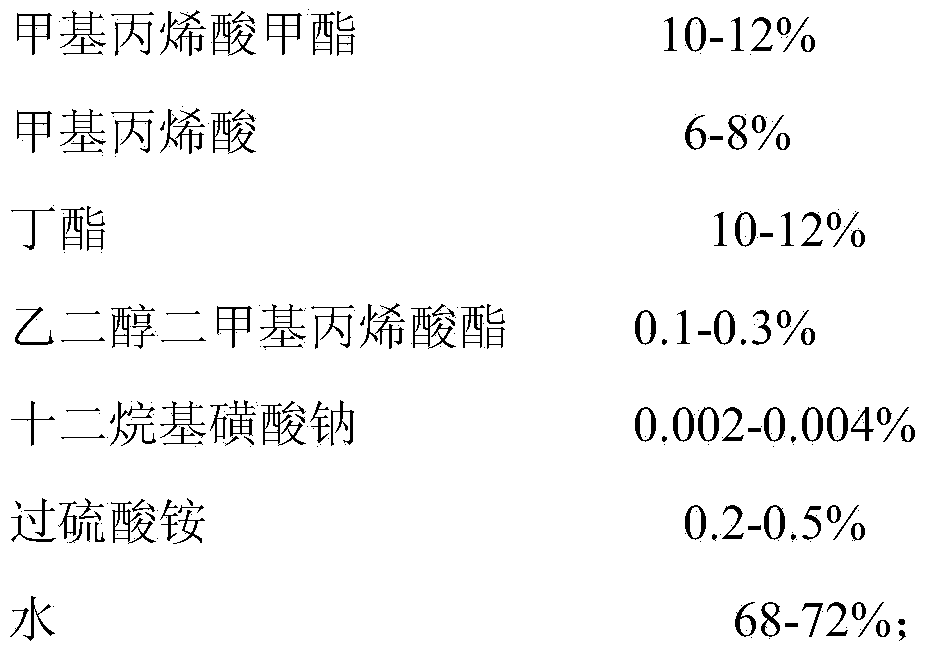

[0056] The preparation process of the above-mentioned polymer core is as follows: first add all the water, ammonium persulfate accounting for 1 / 4 of the total amount, and methyl methacrylate, methacrylic acid, butyl ester and ethylene glycol 2 accounting for 1 / 20 of the total amount. Methacrylate, in 80 o Polymerize at C for 40 minutes, and then add dropwise the remaining 19 / 20 methyl methacrylate, methacrylic acid, butyl ester, ethylene glycol dimethacrylate and the remaining 3 / 4 of ammonium persulfate. This process needs to be at 80 o It lasts for 4.5 hours at C, then it rises to 90 o C keep this temperature for 30 minutes at the same time to obtain a synthetic polymer core emulsion;

[0057] The main components and weight ratios of the first embodiment are as follows:

[0058] Methyl methacrylate 10%

[0059] Methacrylic acid 6%

[0060] Butyl 11.398%

[0061] Ethylene glycol dimethacrylate 0.1%

[0062] Sodium dodecyl sulfonate 0.002%

[0063] Ammonium persulfate 0.5%

[0064] Water 7...

Embodiment 2

[0065] The main components and weight ratios of the second embodiment are as follows:

[0066] Methyl methacrylate 11%

[0067] Methacrylic acid 7%

[0068] Butyl 10%

[0069] Ethylene glycol dimethacrylate 0.2%

[0070] Sodium dodecyl sulfonate 0.003%

[0071] Ammonium persulfate 0.4%

[0072] Water 71.397%

Embodiment 3

[0073] The main components and weight ratios of the third embodiment are as follows:

[0074] Methyl methacrylate 11%

[0075] Methacrylic acid 7%

[0076] Butyl 12%

[0077] Ethylene glycol dimethacrylate 0.25%

[0078] Sodium dodecyl sulfonate 0.003%

[0079] Ammonium persulfate 0.35%

[0080] Water 69.397%

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com