Machine to join or tape a fabric

A technology of textiles and equipment, applied in the field of equipment for jointing or belt jointing textiles, which can solve problems such as inconvenience and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

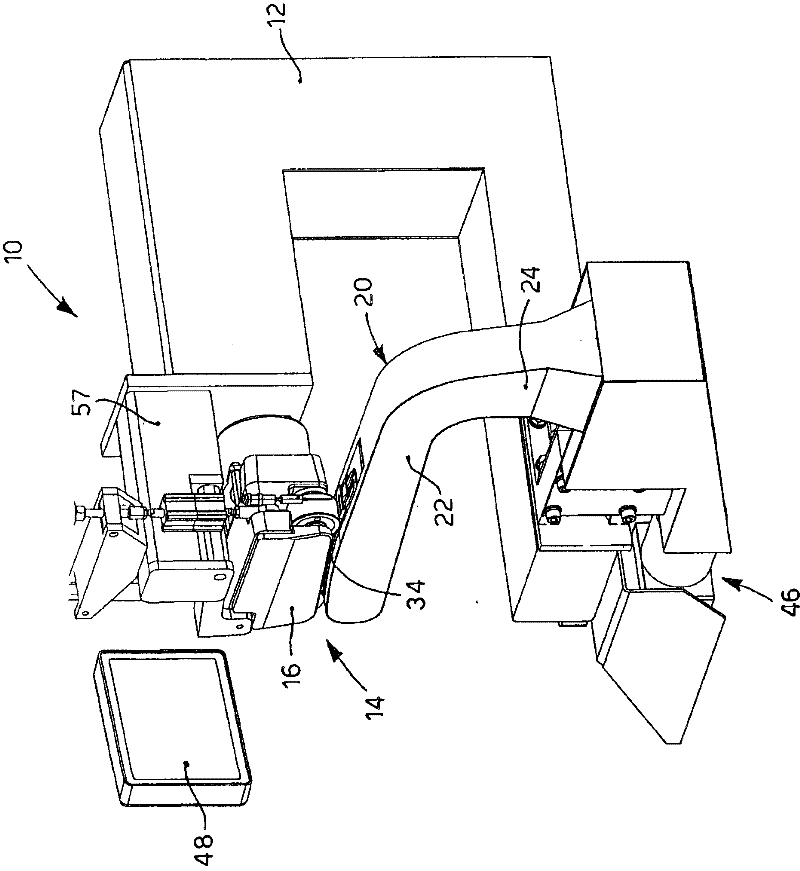

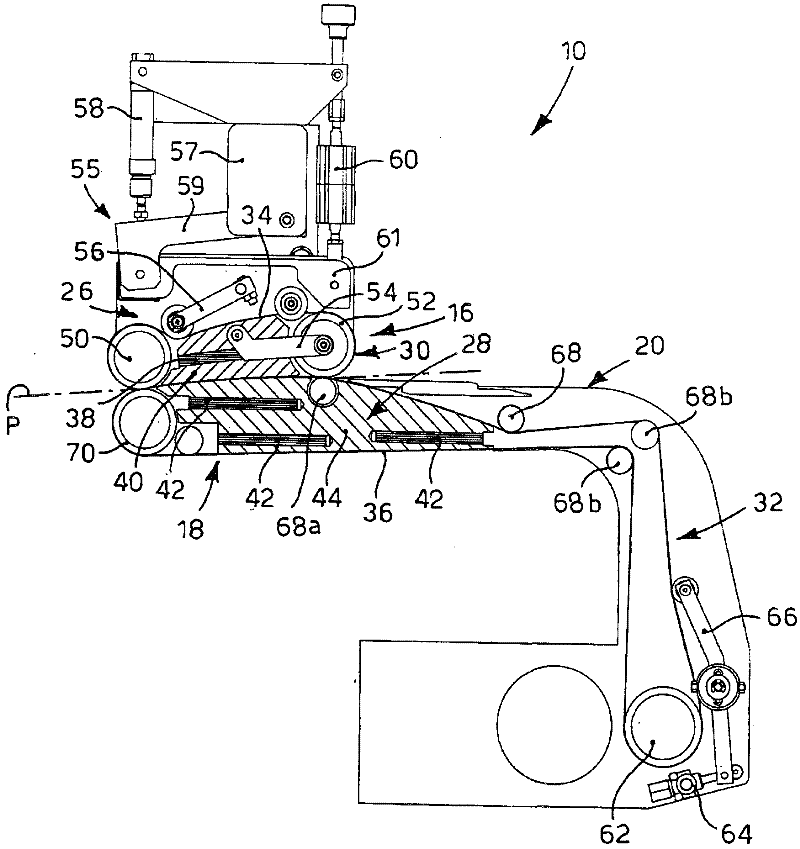

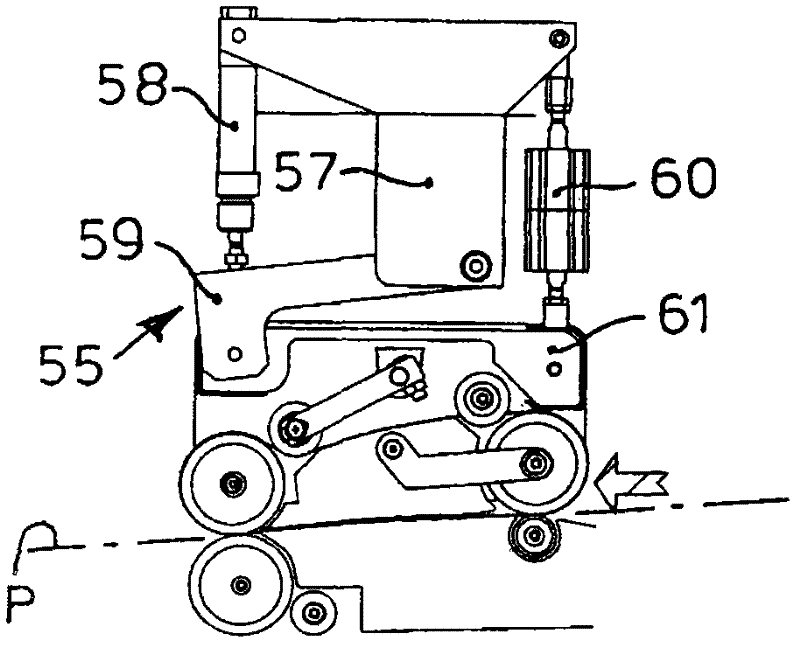

[0051] Referring to the figures, a device 10 according to the invention is used for joining a textile 11 . Specifically, joins such as Figure 6 The two edges 11a, 11b of the separated textile shown in, or the belt joins as Figure 11 The textile shown in has joined the two edges 11a, 11b.

[0052] In the case of joining (this joining operation is also referred to as combining), the two edges 11a, 11b of the textile are joined by an adhesive 13 (usually thermoplastic) that has been placed on the two edges 11a, 11b, the adhesive The binder 13 is used to melt and at the same time apply pressure from one edge to the other. The above-described operations can be carried out in an open mode (ie, the two edges are on a horizontal plane for docking) or a closed mode (ie, the two edges are folded into a tubular structure).

[0053] In the case of belt joining, the two edges 11a, 11b have been combined, but usually the constraints of joining the two edges do not guarantee a mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com