Volute shaped pump casing for a centrifugal pump

A centrifugal pump and volute technology, which is applied to the components, pumps, and pump elements of a pumping device for elastic fluids, can solve the problems of increased mass and high cost of double volutes, and achieves a reduction in material quality and distance, the effect of reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

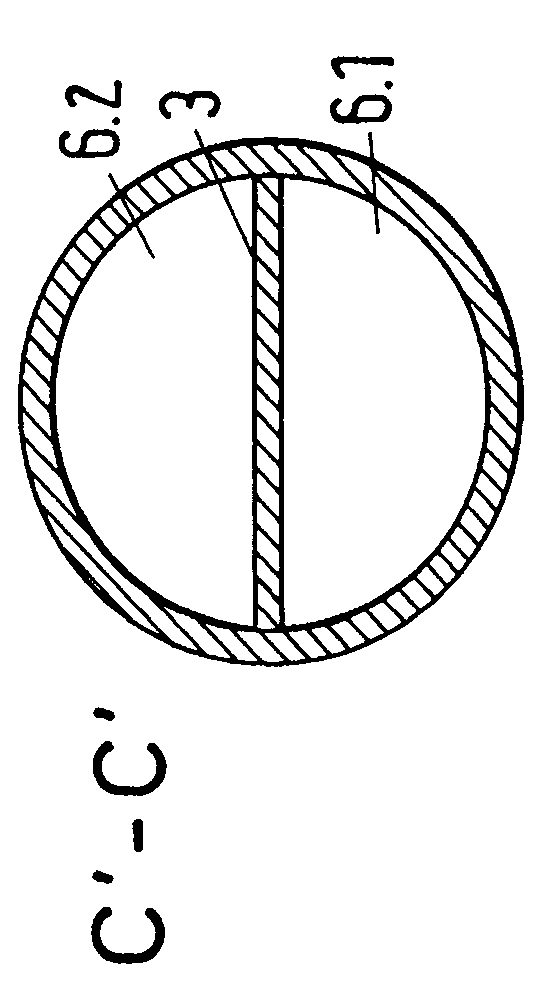

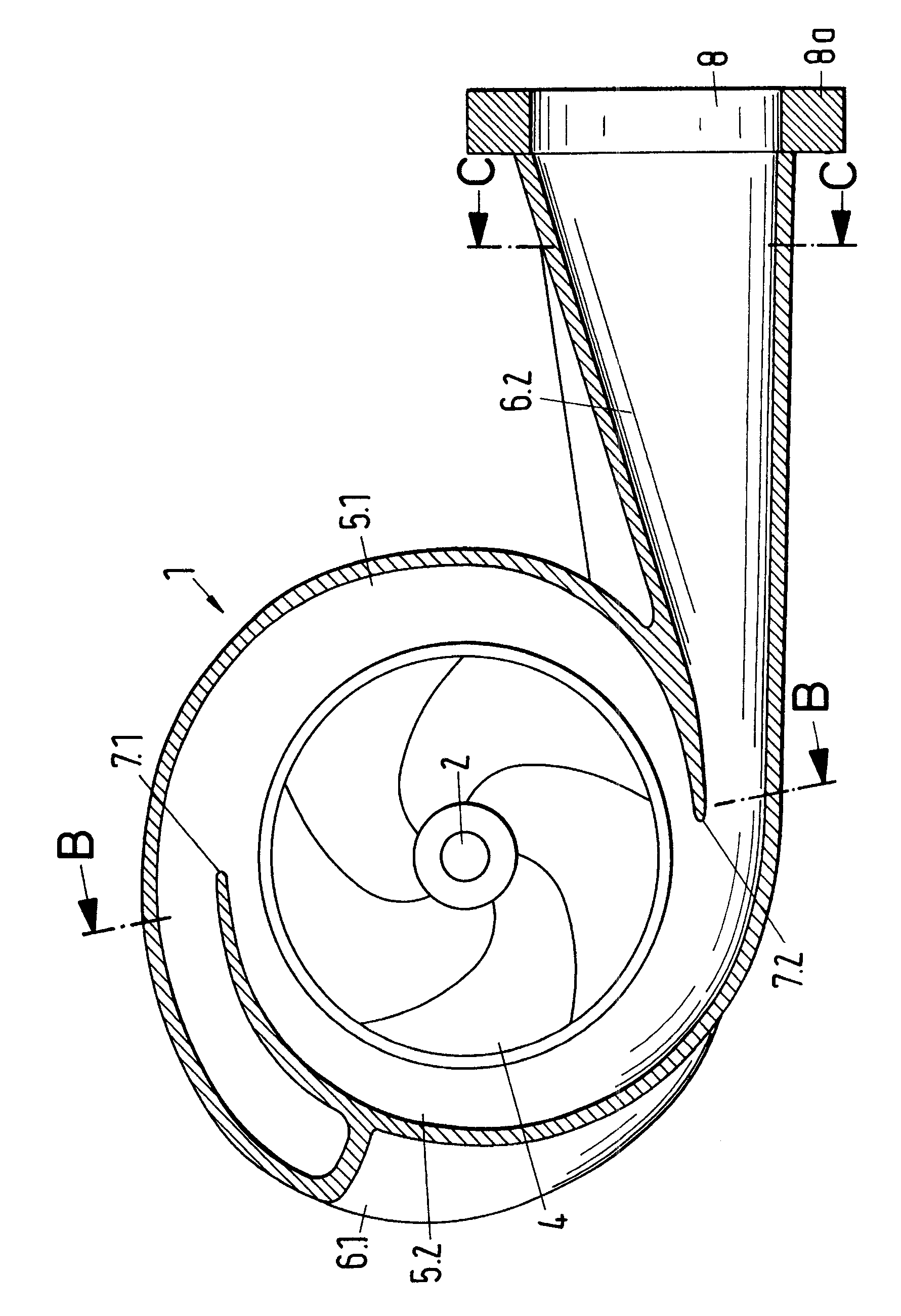

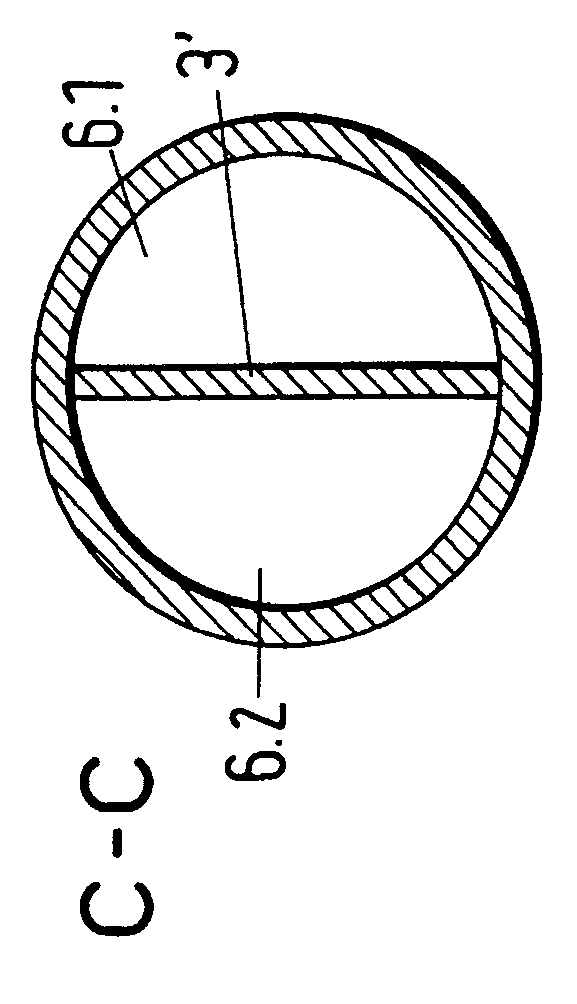

[0028] figure 1 , 1A and 3 show a conventional volute-shaped pump casing 1 for a centrifugal pump, where figure 1 is the section A’-A’ perpendicular to the axis of rotation, Figure 1A is the section C’-C’ through the outlet section, and image 3 is the axial section B'-B' through a conventional volute-shaped pump casing. The illustrated volute-shaped pump casing comprises a chamber for housing at least one impeller 4 mounted on the shaft 2 for rotation about an axis of rotation 2a when driven, for example by a motor. The housing further comprises a volute chamber forming a flow channel which is divided into a first volute 5.1 extending generally half a circle or less than half a circle respectively, and a first channel 6.1 and a second channel 6.2 As well as the second volute 5.2, the first channel 6.1 and the second channel 6.2 are respectively connected to the first and second volute to lead out the pumped medium.

[0029] Advantageously, the casing comprises at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com