Corner cutting circuit in LCD driving system

A driving circuit and driving system technology, applied in the field of LCD driving, can solve problems such as temperature rise of the discharge module, burning of the discharge module, high temperature generation, etc., and achieve the effect of releasing control board space, avoiding crowded arrangement, and avoiding high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

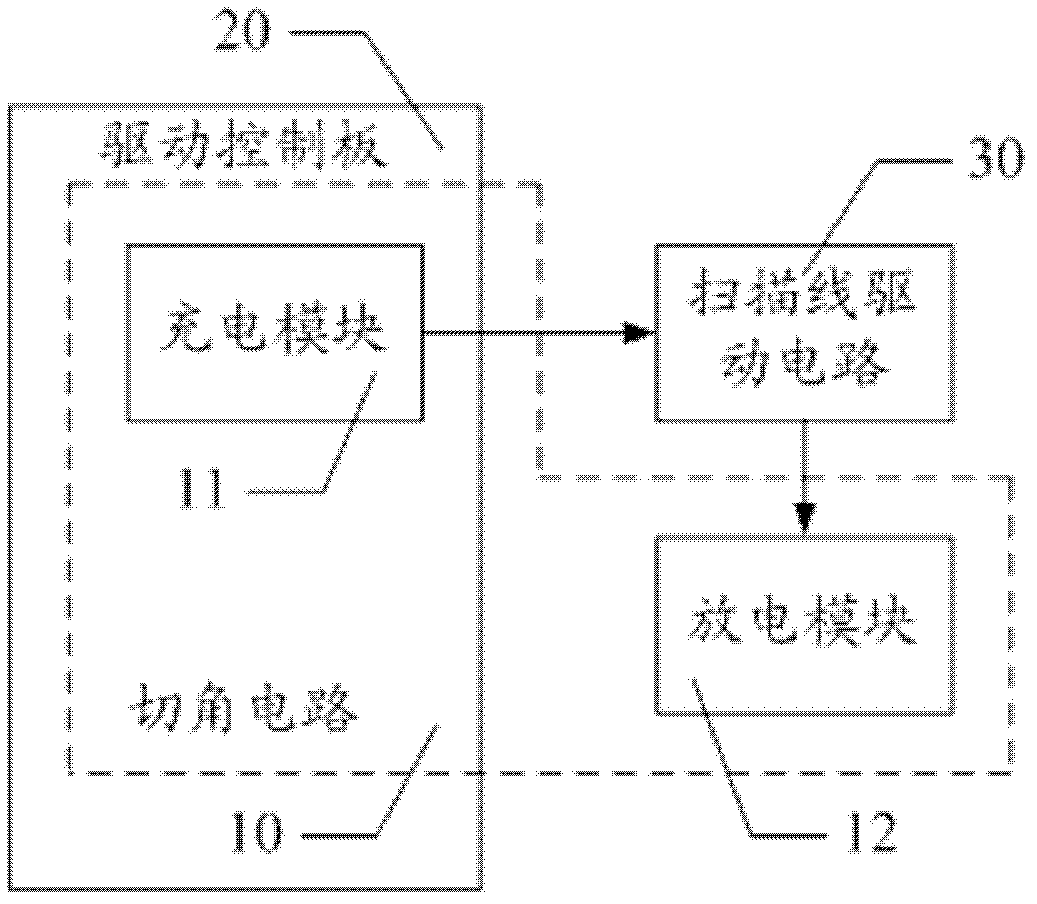

[0037] Such as figure 1 As shown, the corner cutting circuit 10 in the LCD driving system mentioned in the embodiment of the present invention is connected to a plurality of scanning line driving circuits 30, including:

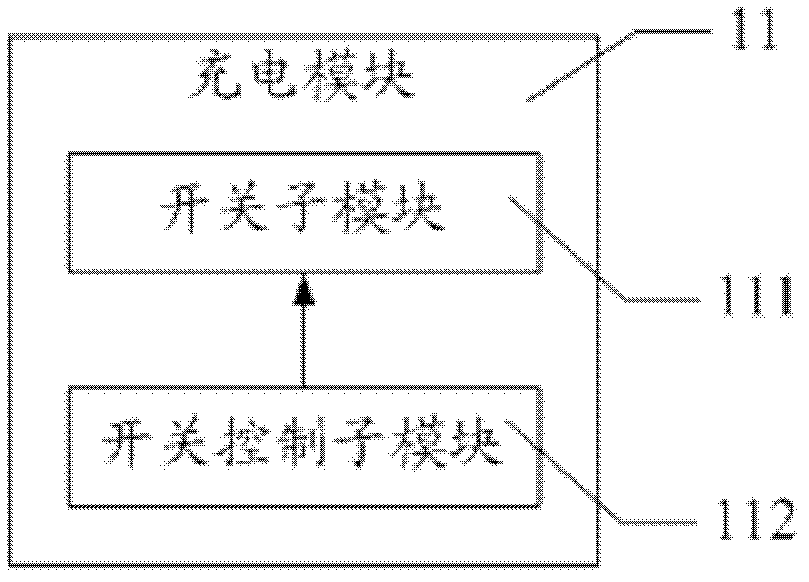

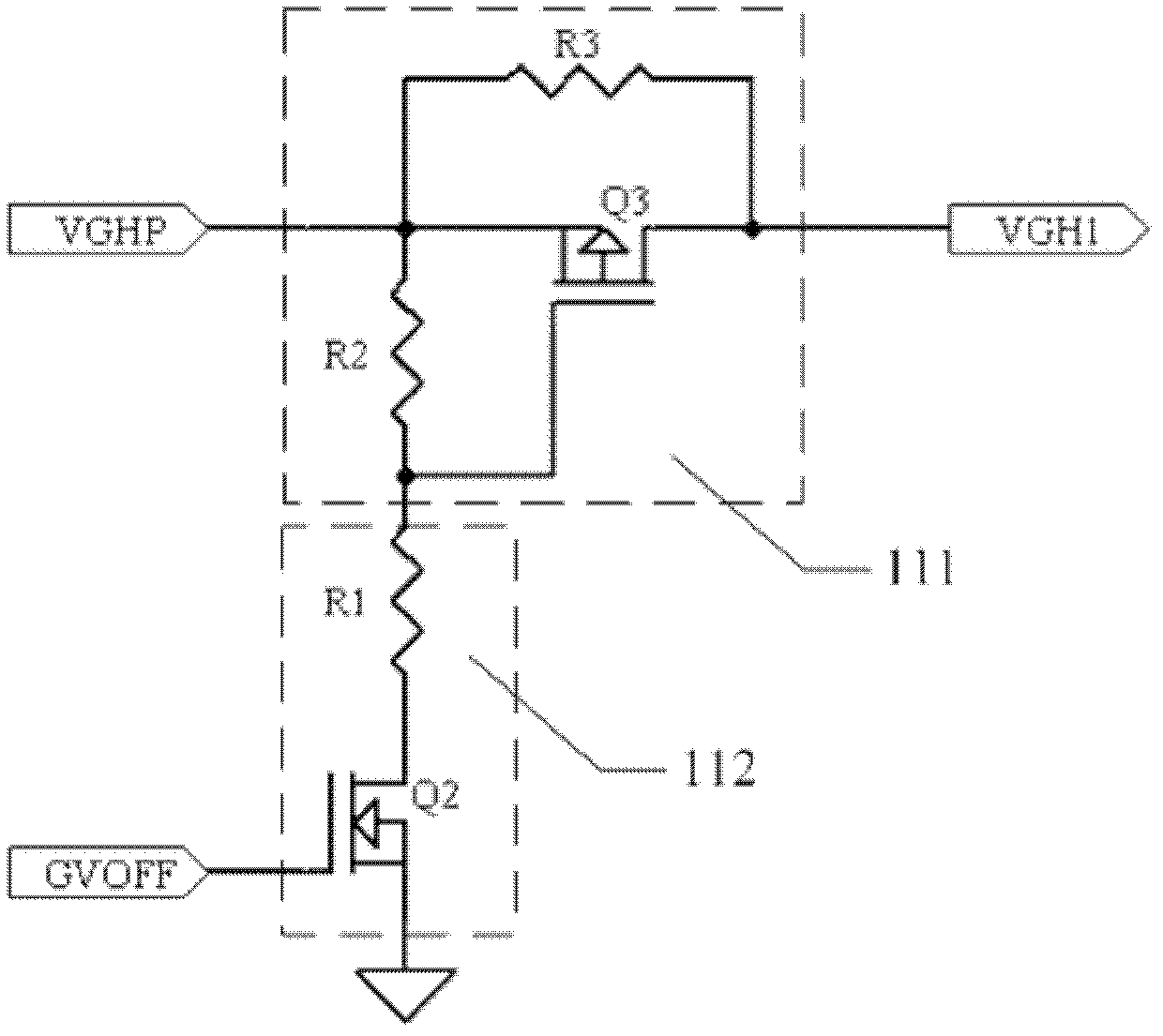

[0038] The charging module 11 is integrated on the control board 20, accepts the input of the DC driving voltage, and outputs the turn-on voltage to charge the scanning line driving circuit 30;

[0039] A plurality of discharge modules 12 are respectively integrated on each scanning line driving circuit 30 to control the corresponding scanning line driving circuit 30 to discharge.

[0040] In this embodiment, there may be multiple discharge modules 12 that control the discharge of the scan line drive circuit 30. This embodiment only takes one discharge module 12 as an example, and each discharge mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com