A laser pipe cutting machine

A tube cutting machine and laser cutting technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problem of inability to take out small sections of pipes in sections, and achieve the goal of improving the quality rate, avoiding crowding, and improving working hours. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

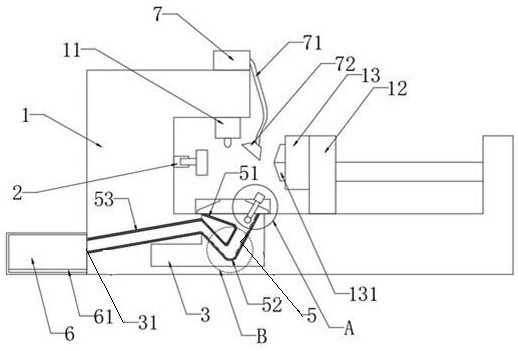

[0036] Embodiment one, with reference to figure 1 As shown, a laser pipe cutting machine includes a device body 1, a push plate 2 is fixed on one side of the inner wall of the working space of the device body 1, and a laser cutting part 11 is fixed on the top of the inner wall of the working space. The laser cutting part 11 is a working part. A fixed plate 12 is fixed on the bottom of the inner wall of the working space, and a fixed block 13 is arranged on the side of the fixed plate 12 close to the push plate 2 , and a chuck 131 is arranged on the fixed block 13 . The chuck 131 is facing the platen 2 . One side of the device body 1 is provided with a cooling oil placement groove 3 , and cooling oil is placed inside the cooling oil placement groove 3 . When the small section of pipe enters the inside of the cooling oil placement groove 3, due to the effect of the cooling oil, the small section of pipe will not directly contact with the cooling oil placement groove 3, so as t...

Embodiment 2

[0045] Embodiment two: refer to Figure 2-Figure 3 As shown, the difference between embodiment two and embodiment one is:

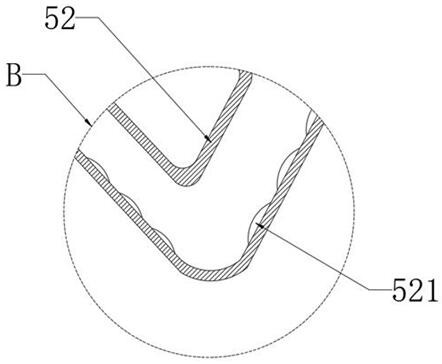

[0046] One side of the inner wall of the V-shaped tube 52 is provided with a plurality of clamping pads 521 equidistantly along its own shape;

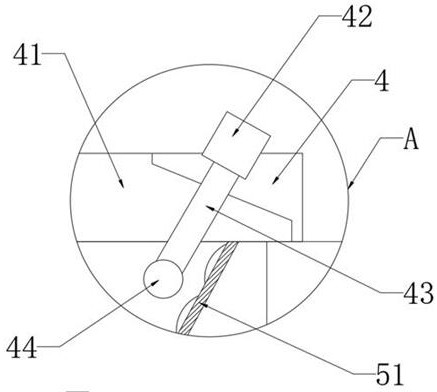

[0047] The top of the splash-proof block 4 is provided with a telescopic part 42, the moving end of the telescopic part 42 is fixed with a connecting rod 43, and the other end of the connecting rod 43 is fixed with a push block 44; parallel.

[0048] The specific implementation process,

[0049] In actual work, the cut small section of pipe falls into the inside of the tapered through hole 41 inside the splash block 4 , and the small section of pipe falls from the tapered through hole 41 into the horn through pipe 51 . At this moment, the small section pipe is submerged in the cooling oil in the cooling oil placement groove 3 inside.

[0050] Due to its own gravity, the small section of pipe enters the V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com