Stepping motor

A technology of stepping motors and rotating shafts, applied to electrical components, electromechanical devices, electric components, etc., can solve problems such as unreliable center guides, complicated manufacturing processes, and motor failures, and achieve small size and thickness and reduced number of components , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, a stepping motor according to the present invention will be described in detail with reference to the accompanying drawings.

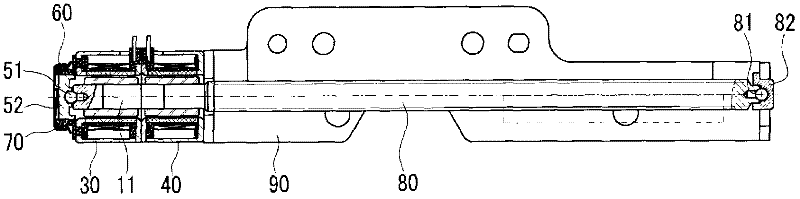

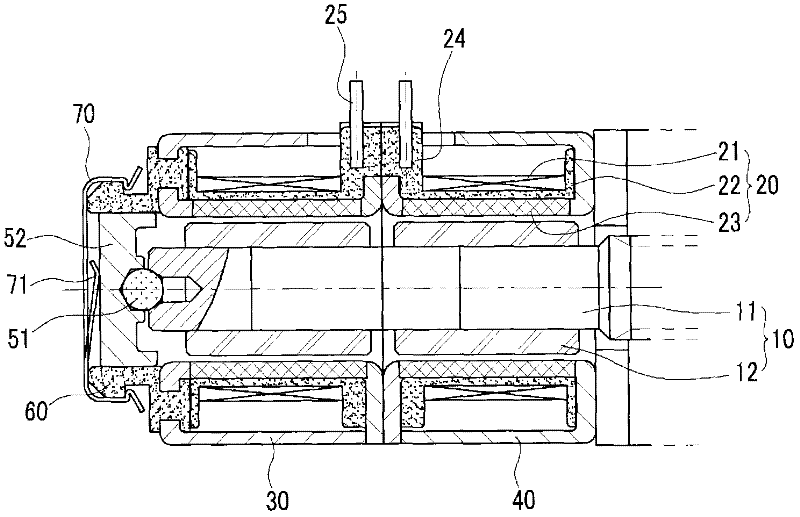

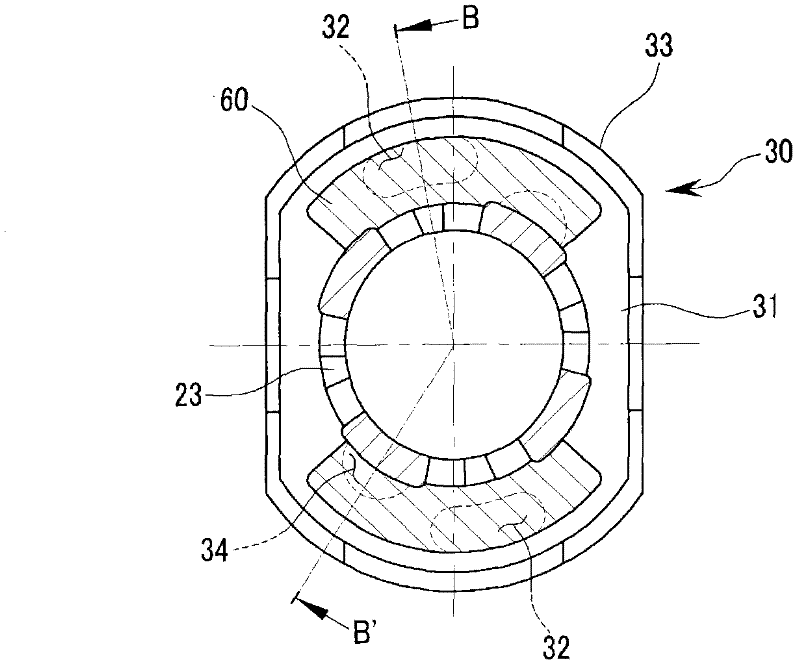

[0025] figure 1 For a view showing the overall configuration of a stepping motor according to the present invention, figure 2 for figure 1 An enlarged view of the motor part of the stepper motor; image 3 is a plan view illustrating an embodiment of a stepping motor housing according to the present invention; and Figure 4 for along image 3 A cross-sectional view taken along line B-B' of , showing the connection of the elastic member to the housing.

[0026] Such as figure 1 and figure 2 As shown, the stepping motor according to the present invention includes a motor portion and a lead screw 80 . The motor part includes a rotor 10 , a stator 20 , and cases 30 and 40 . The rotor 10 includes a rotating shaft 11 and a magnet 12 provided on a circumferential outer surface of the rotating shaft 11 . The stator 20 includes a b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap