Temperature sensing type integrated thermostat device used in engine oil module

A technology of temperature-sensing and thermostat, which is applied in the direction of machine/engine, lubrication indicating device, engine lubrication, etc. It can solve the problems of weak firmness, cumbersome installation, difficult disassembly and maintenance, etc., so as to save design space and facilitate The effect of dismantling maintenance and optimizing the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

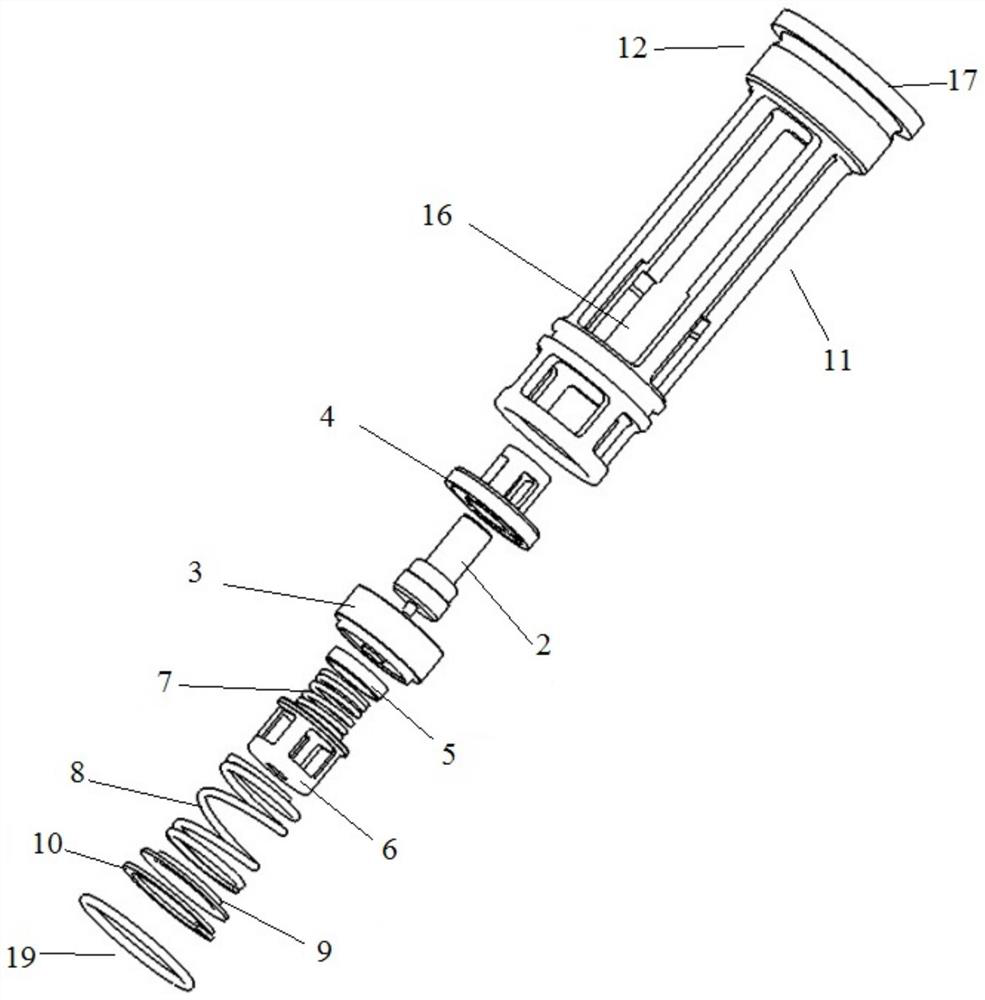

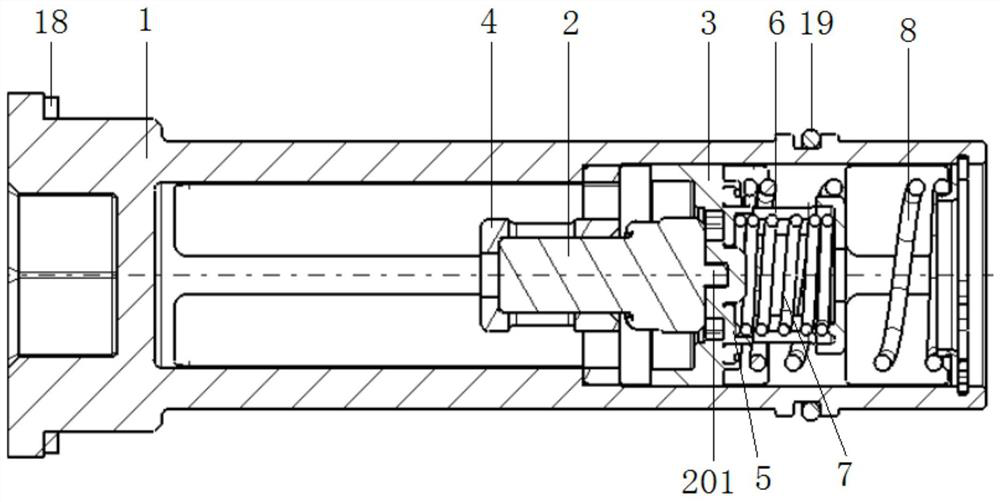

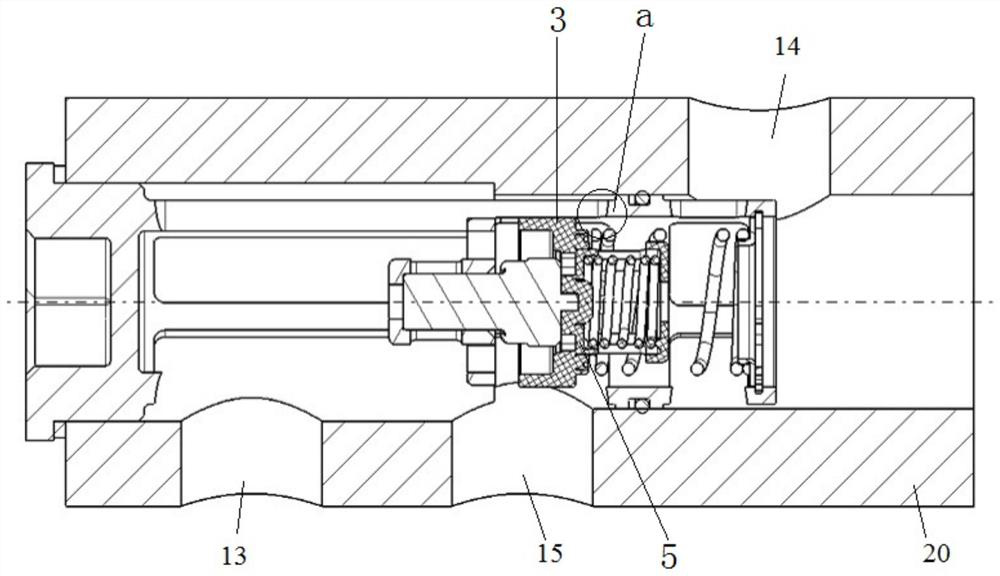

[0034] refer to Figure 1-4 , a temperature-sensing integrated thermostat device used in an oil module, including a housing 20, a bracket 1, a temperature-sensing element assembly, a bypass valve assembly, and a retractable limit assembly, wherein the housing 20 There is a hollow cavity, the bracket 1 is installed in the hollow cavity of the housing 20, the temperature sensing element assembly and the bypass valve assembly are integrally installed inside the bracket 1, and are limited by the retractable limit assembly installed at one end of the bracket 1. Position, the retractable limit assembly includes a spring 8, a spring retainer 9 and a circlip 10 connected in sequence, the spring is connected to the end of the bypass valve seat 6, and the circlip 10 is connected to the bracket 1 in a limited position.

[0035] The support 1 is a hollow sleeve structure, including a support cylinder 11 and a support cover 12, the support cover 12 is arranged at one end of the support cyl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap