Rubber membrane seal gas tank with air-jet air cushion buffer device

A technology of buffer device and gas tank, applied in the field of gas tank, can solve the problems of collision friction, easy peeling off of rubber film, damage of outer casing, etc., and achieve the effect of high-efficiency operation, optimization of piston weight adjustment system, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below.

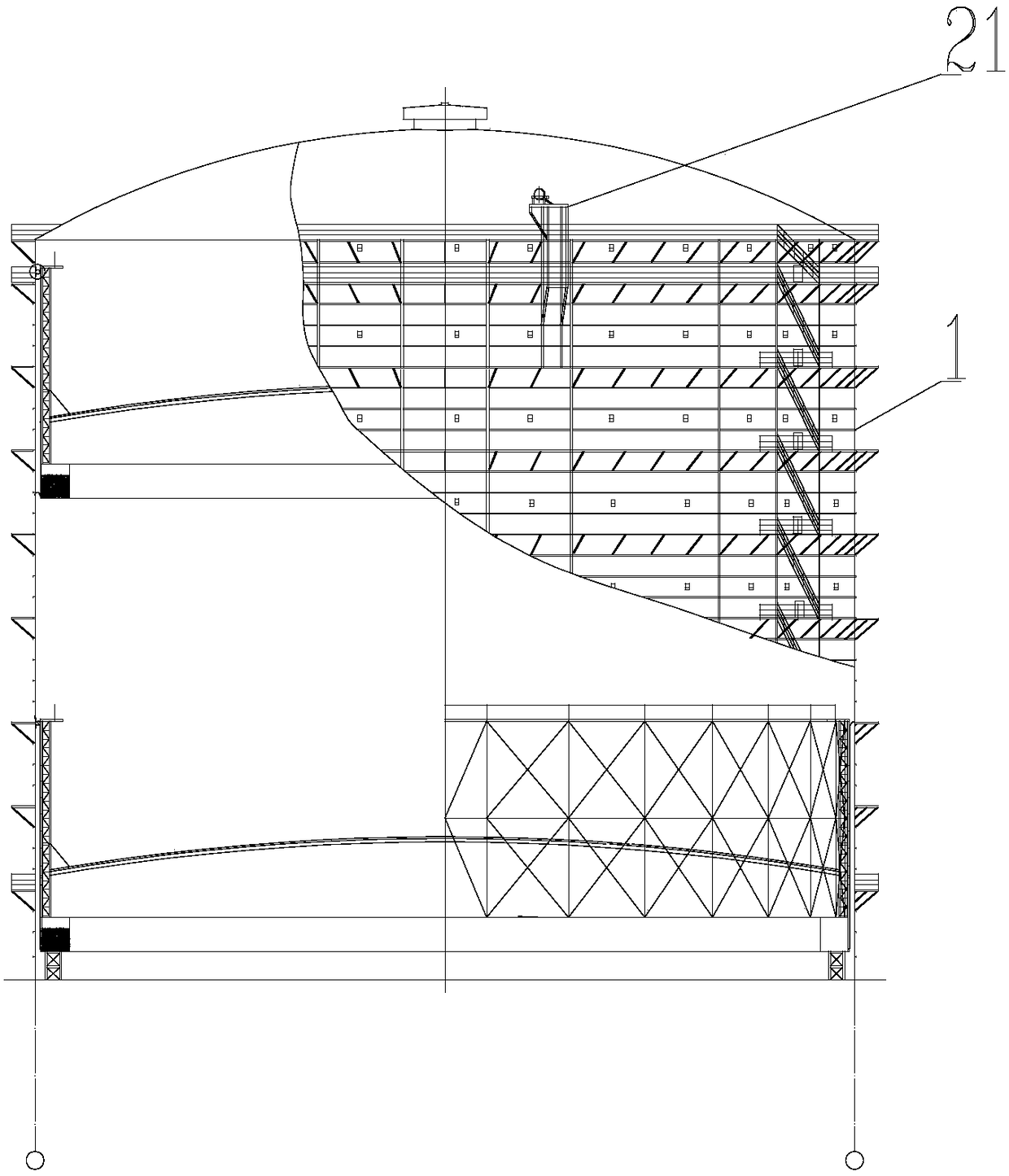

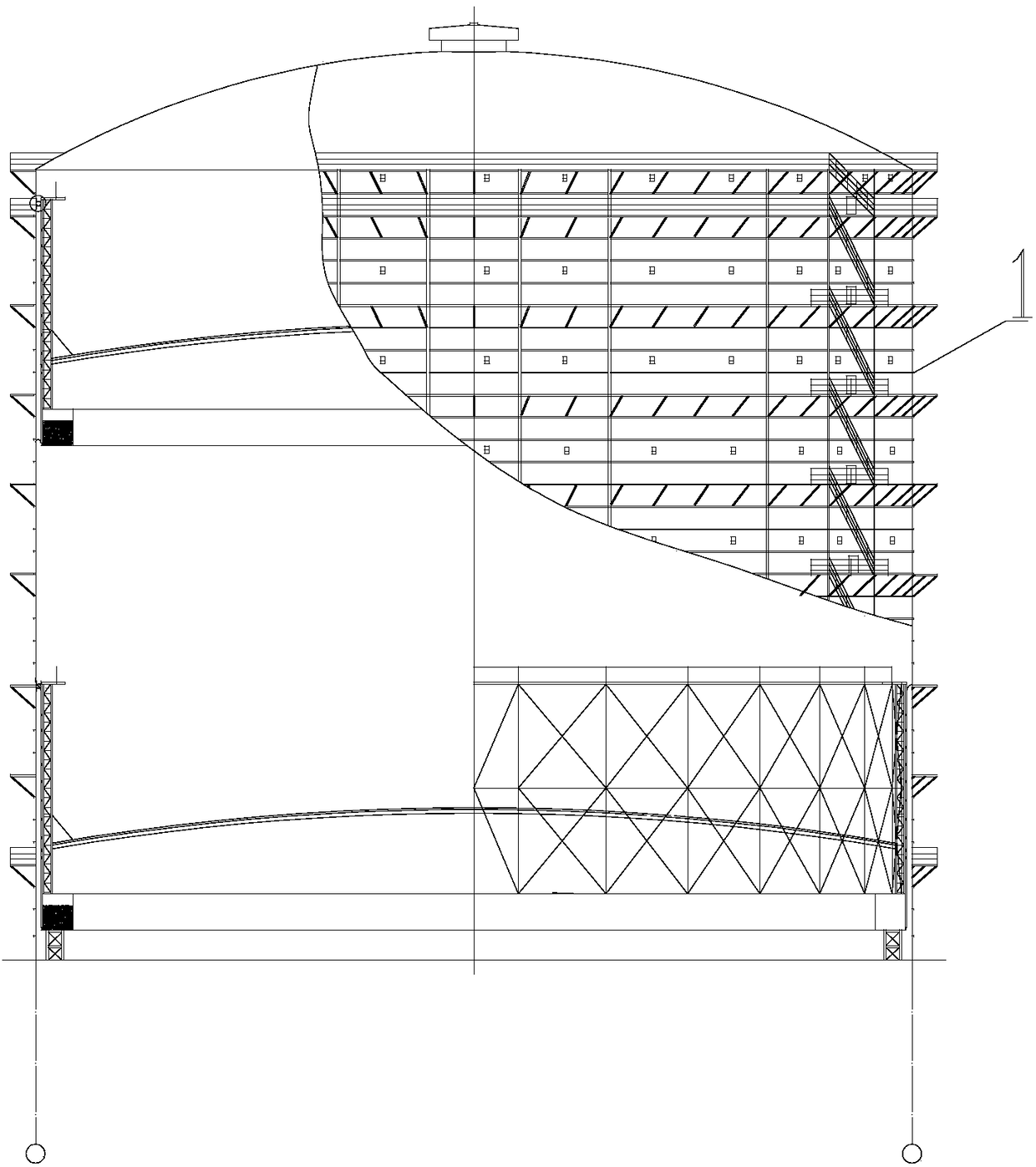

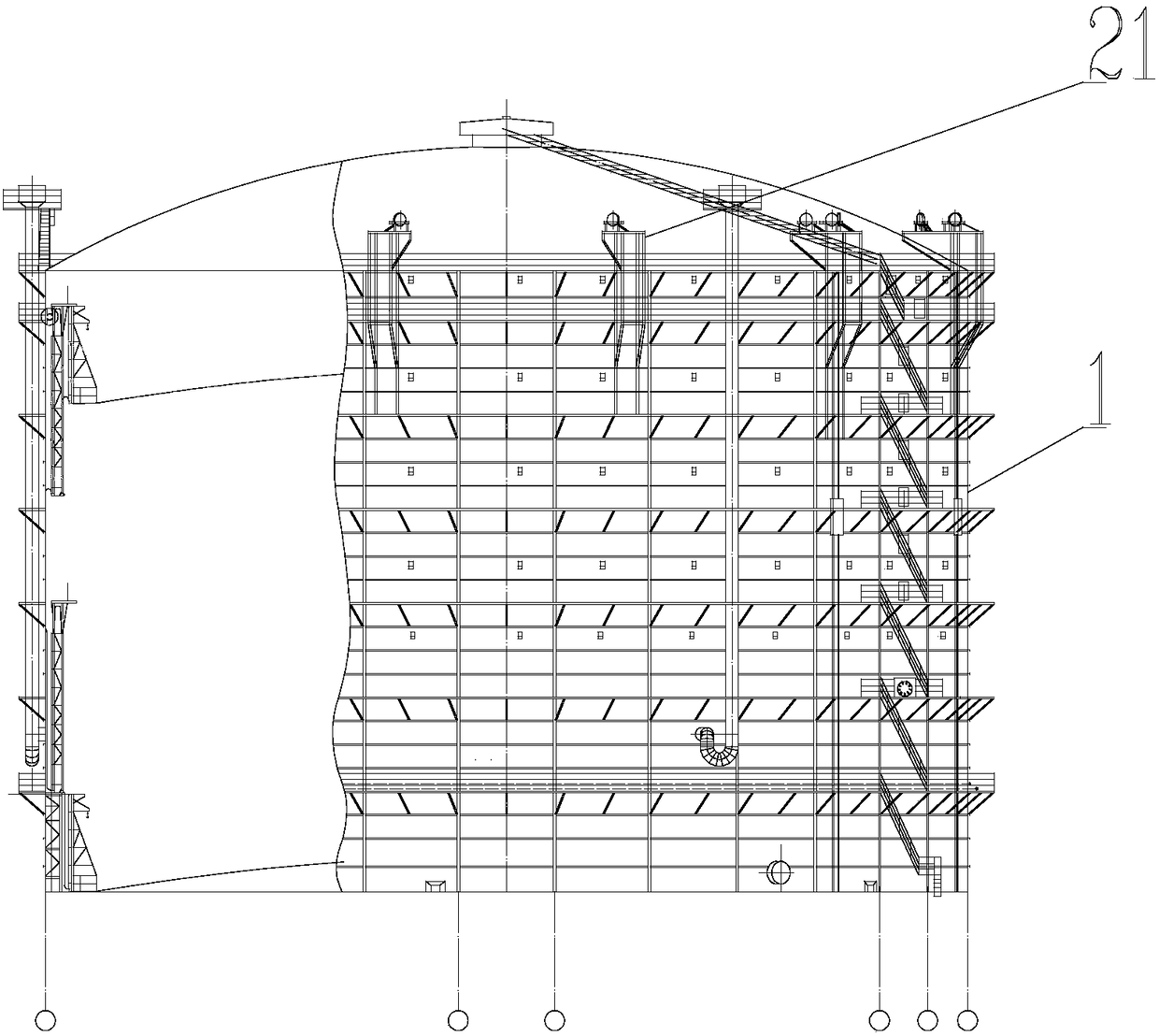

[0033] The reference signs in the accompanying drawings of the specification include:

[0034] Gas tank cylinder 1, rubber membrane 2, gas tank piston 3, jet air cushion airbag 4, jet cylinder skirt 5, air cushion 6, air cushion inner sealing plate 7, first jet air cushion airbag pressure 8, piston anti-tilt guide wheel 9, Jet air cushion airbag fixing device 10, gas inlet pipe 11, gas inlet control valve 12, gas inlet control valve instrument control line 13, gas inlet pipeline 14, gas source 15, second jet air cushion airbag pressure 16, piston buoyancy center 17 , piston mass center of gravity 18, rubber membrane gyration center 19, gas pressure stored in the first gas tank 20, weight leveling device 21, cabinet top wire rope guide wheel frame 22, cabinet top wire rope sleeve 23, leveling wire rope 24, pulley Platform rope guide frame 25, first group of steel wire ropes 26, second gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap