Air filter assembly

An air filter and filter technology, applied in the direction of fuel air filter, combustion air/combustion-air treatment, machine/engine, etc., can solve the complex structure of air filter, fatigue fracture of air filter bracket, Large installation space and other problems, to achieve the effect of improving appearance and product consistency, avoiding fatigue fracture, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

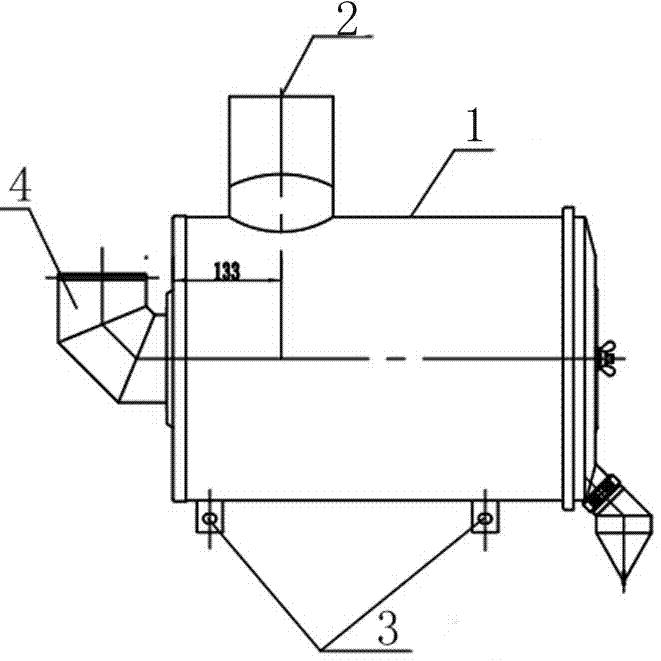

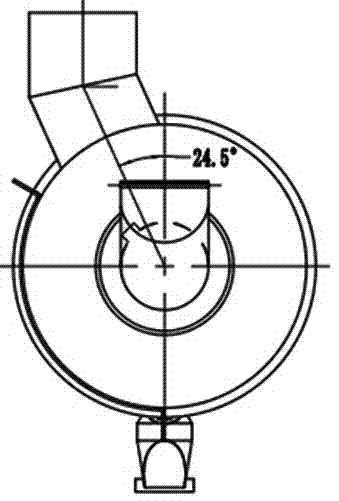

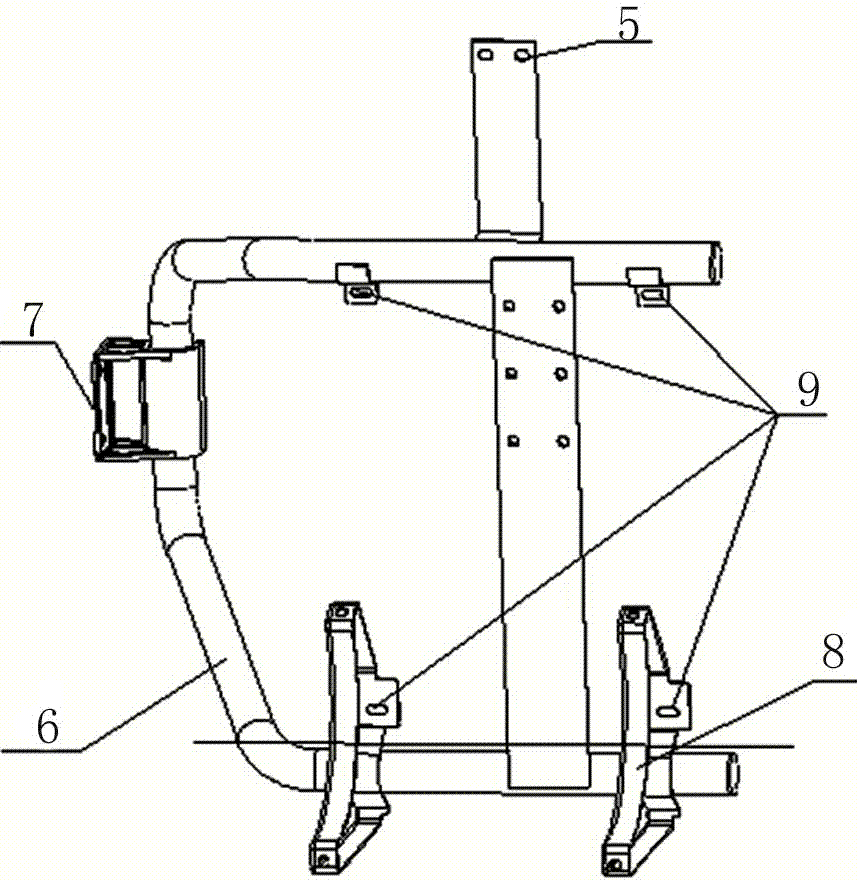

[0017] The present invention as figure 1 , 2 , 3, 4 shown.

[0018] An air filter assembly, including an air filter body (1), a filter element and an air filter bracket (6) arranged in the filter body (1), and the air filter body (1) passes through a clamp (3) Connected to the air filter installation support (8), the air filter body (1) air inlet (2) is connected to the air intake pipe of the T702 body through a telescopic rubber hose, and the air outlet is connected to the intake steel pipe to provide air intake for the engine ;The air filter bracket (6) is fixed on the outer wing surface of the vehicle frame through the installation plane (7), and the upper part of the air filter bracket (6) contains a connecting plate and a mounting hole (5) for fixing the air induction pipe, and at the same time the air filter The inner frame of the bracket (6) is provided with four fender mounting holes (9) for assembling the fender bracket.

[0019] The air inlet (2) of the air filter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap