Injection molding method and injection molding device

A technology of injection molding and stop position, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., and can solve problems such as reduced reliability, increased cost, and lengthened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

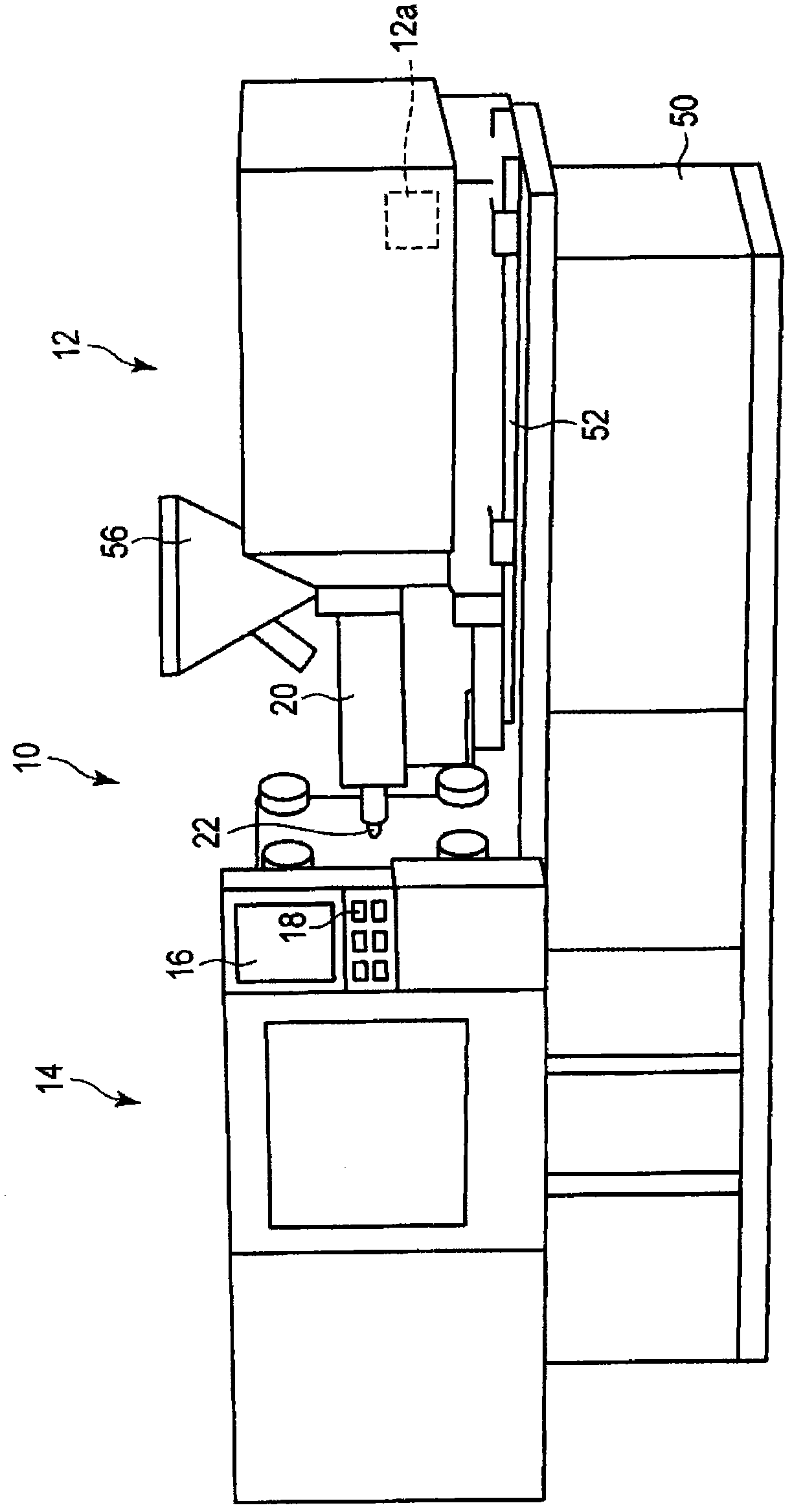

[0016] figure 1 It is a perspective view showing the injection molding apparatus 10 for carrying out the injection molding method of the present invention. The injection molding device 10 has a base 50 on which the injection device 12 , the mold clamping device 14 , the display device 16 , and the operation panel 18 are provided. The injection molding apparatus 10 mainly molds molded products having fine shapes.

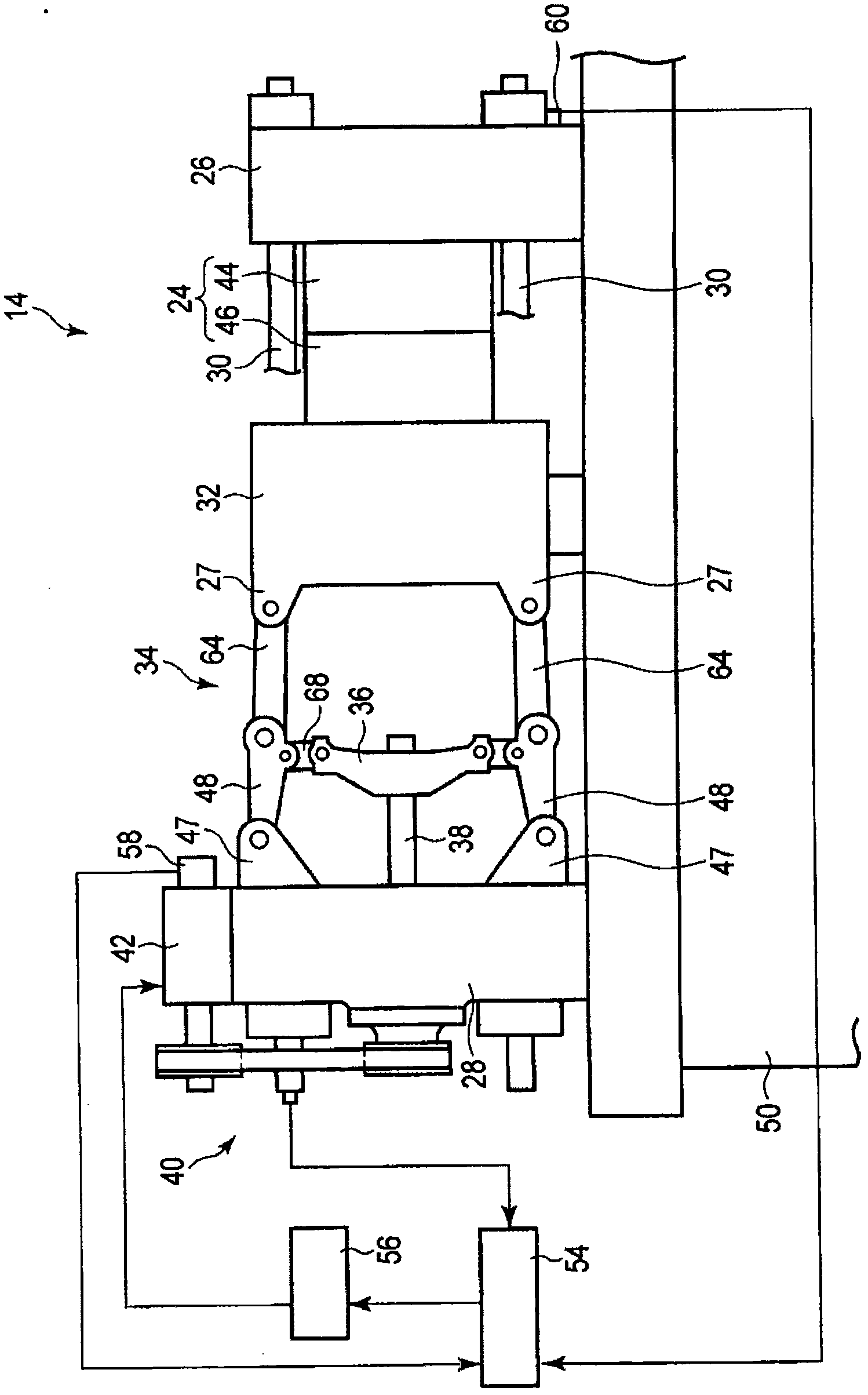

[0017] The injection molding device 12 includes: a cylinder body 20; a screw rod that is arranged to be rotatable and can advance and retreat inside the cylinder body 20; a screw drive mechanism that makes the screw rod rotate inside the cylinder body 20 and advance and retreat; and a heater that heats the cylinder body 20 The above-mentioned injection molding device 12 is set to be freely movable on the guide rail 52 . The injection molding device 12 is controlled by the injection control unit 12a that operates together with the mold control unit 54 described late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com