Horizontal well landing geosteering method

A horizontal well and geosteering technology, applied in directional drilling, earthmoving, wellbore/well components, etc., can solve the problems of poor seismic data quality, low well control degree, large structural interpretation error, etc., and achieve calibration design Structural error, ensuring the success rate of drilling, the effect of ensuring the success rate of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

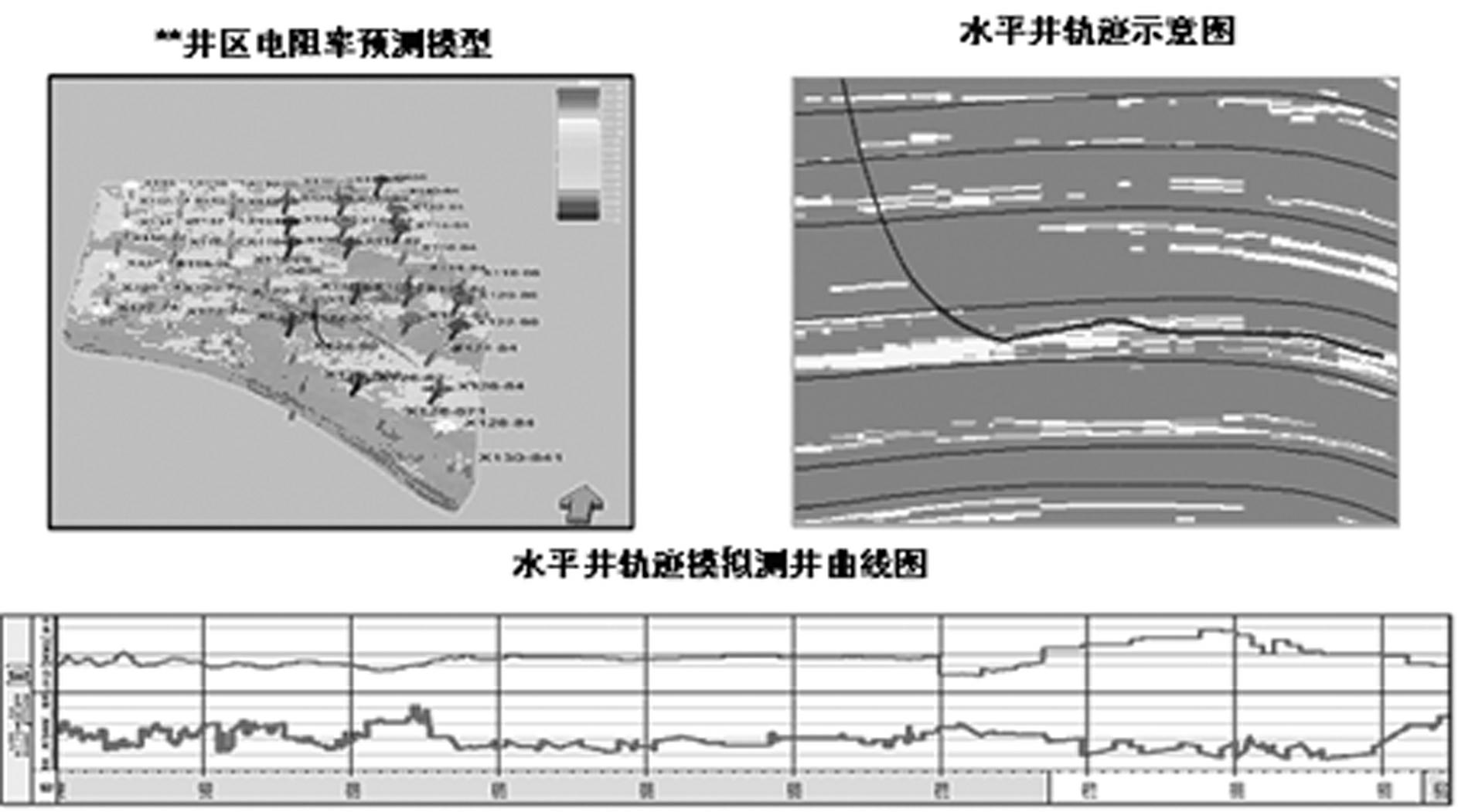

[0037] Example 1. Well N243-P297, the design target layer is PI4-3 layer, and the structural sand body model of the target area is established. The vertical depth of the landing point of the target layer is estimated to be 1272.84m, see Figure 4 .

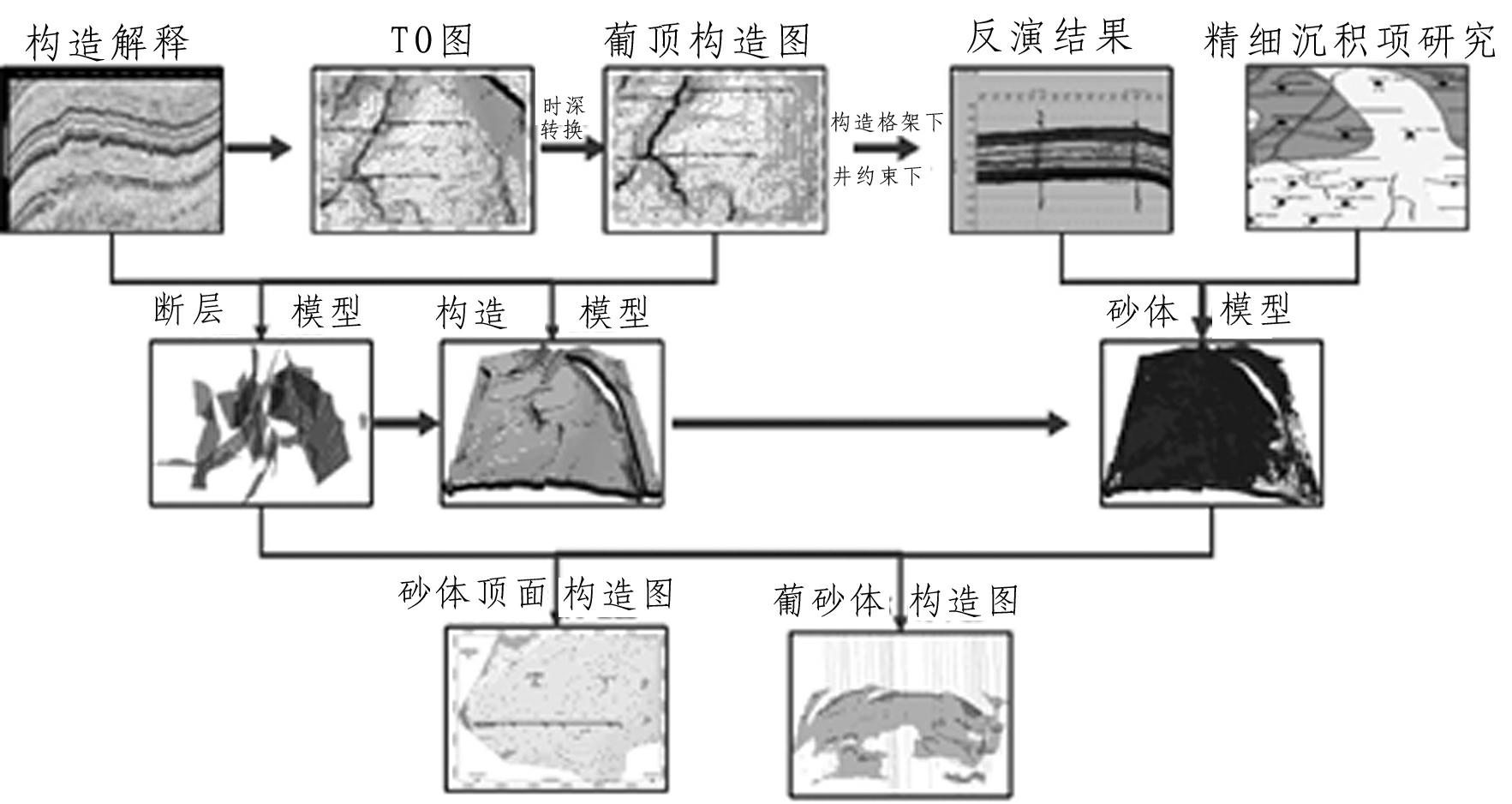

[0038] Based on the establishment of the structural sand body model, combined with the electrical logging curves of the surrounding wells, the electrical influence model of the target area is established to realize the purpose of real-time simulation of the logging curves with any trajectory, see figure 2 .

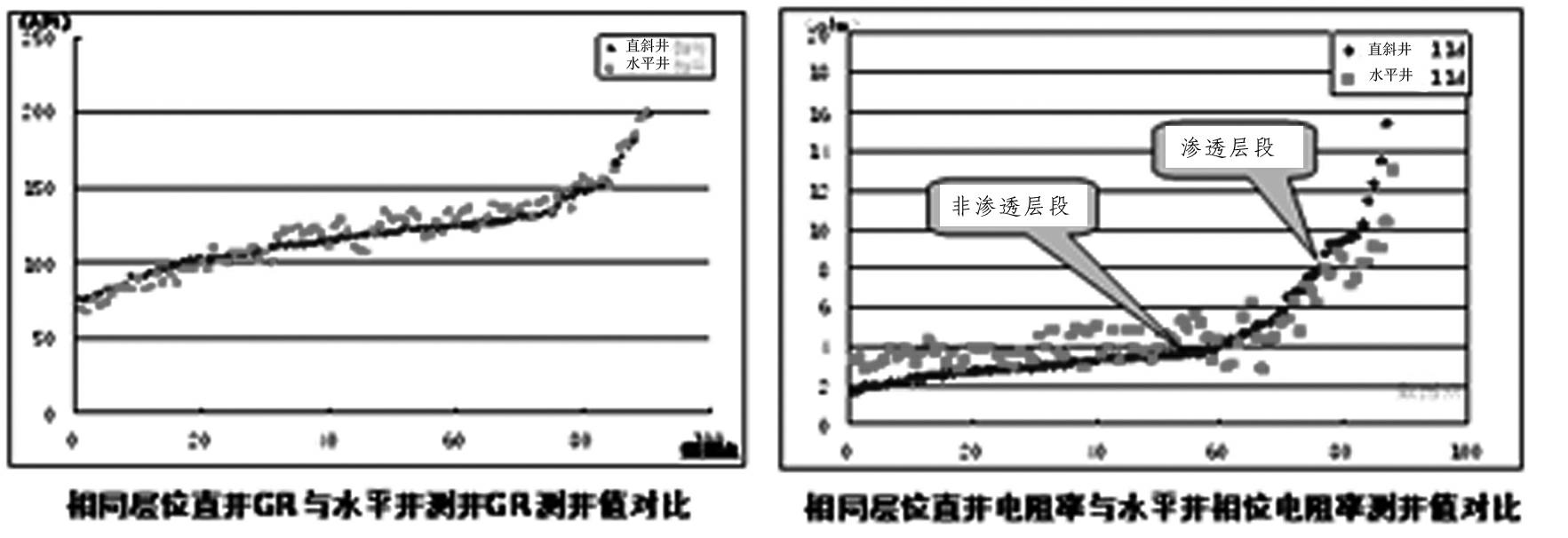

[0039] During the landing process, the real drilling curve data will be corrected by software first. Adding it to the landing comparison model, comparing the shape difference between the horizontal well curve and the vertical well curve, can accurately identify the currently drilled layer. Compare sections one by one to judge structural changes, determine the true vertical depth of the landing point, and design the most re...

Embodiment 2

[0043] Example 2: Well N266-P251, the design target layer is PI1-2 layer, and the vertical depth of the target layer at the expected landing point is 1260.62m.

[0044] When drilling to mark point 6, according to the calculation of Well N266-250, the current vertical depth should be 1252.5m (actually drilled 1247.5m), which is 5.0m shallower than the design. According to the calculation of Well N266-252, the current vertical depth should be 1253.1m (actual Drilling 1247.5m), 5.6m shallower than the design ( Figure 9 ). It is considered that the wellbore trajectory needs to be adjusted in time to prevent layer penetration.

[0045] After section-by-section comparison, it was finally determined that the actual drilling target layer was 5.6m ahead of the design ( Figure 10 ), redesign the well trajectory, increase the inclination at a large angle, and finally land smoothly. The drilling rate of this well was 94.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com