FISHFARM float section experiment model

An experimental model and segmented module technology, which is applied in the field of marine engineering, can solve the problems of no buoy segmented boundary processing, large scale effect, and can only measure the overall force of the net, so as to solve the boundary effect and avoid the scale effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

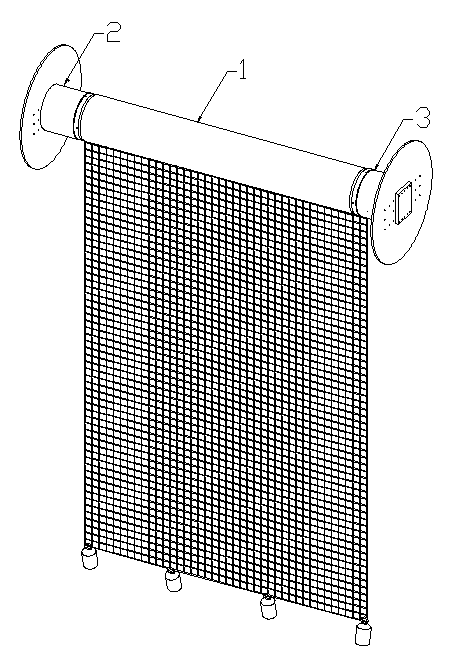

[0019] Such as figure 1 and Figure 5 As shown, the experimental model provided according to the present invention includes: a pontoon segment module 1, a first end prosthesis module 2, a second end prosthesis module 3 and a measurement analysis module 4, wherein: both ends of the pontoon segment module 1 They are respectively connected to the first end prosthesis module 2 and the second end prosthesis module 3, and the measurement analysis module 4 is respectively connected to the buoy segment module 1, the first end prosthesis module 2, and the second end prosthesis module 3 connected.

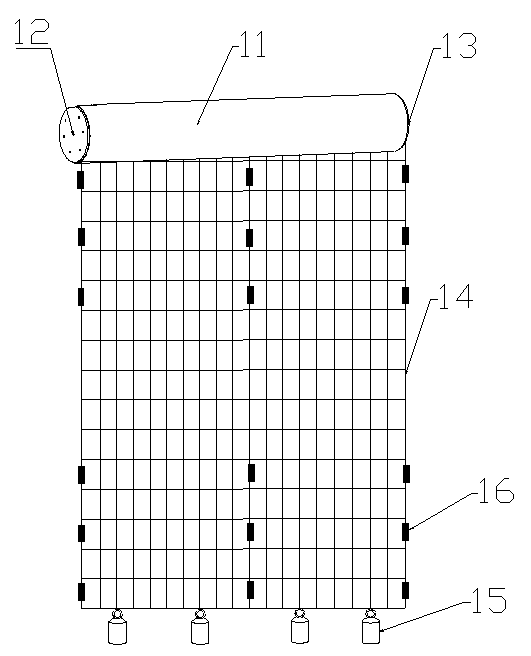

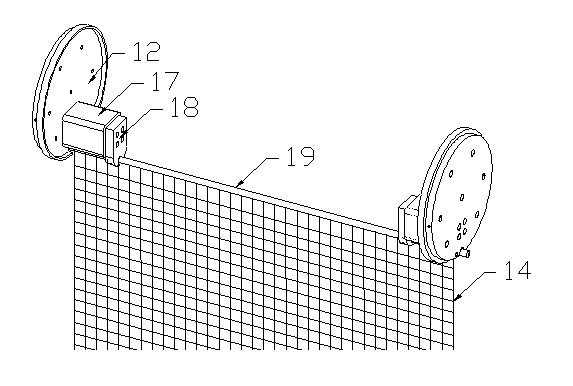

[0020] Such as figure 2 and image 3 As shown, the buoy segment module 1 includes: a support rod 19, a hook 18, an optical fiber sensor 16, a weight 15, a fishing net 14, a buoy segment model 11, a first fixed joint 12, a second fixed joint 13 and two The third three-component force meter 17, wherein: the optical fiber sensor 16 is arranged on the fishing net 14, the weight 15 is arrang...

Embodiment 2

[0024] In this embodiment, the shapes of the first end prosthesis module 2 and the second end prosthesis module 3 can be changed accordingly in order to meet the boundary conditions, such as Figure 6 As shown, this does not affect the essence of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com