Concrete collapsed slump on-line monitoring method and detection device

A detection device and slump technology are applied in the field of concrete slump on-line monitoring and detection devices, which can solve the problems of high price, inaccurate measurement accuracy, and inability to detect changes in slump, and achieve low cost and guaranteed measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

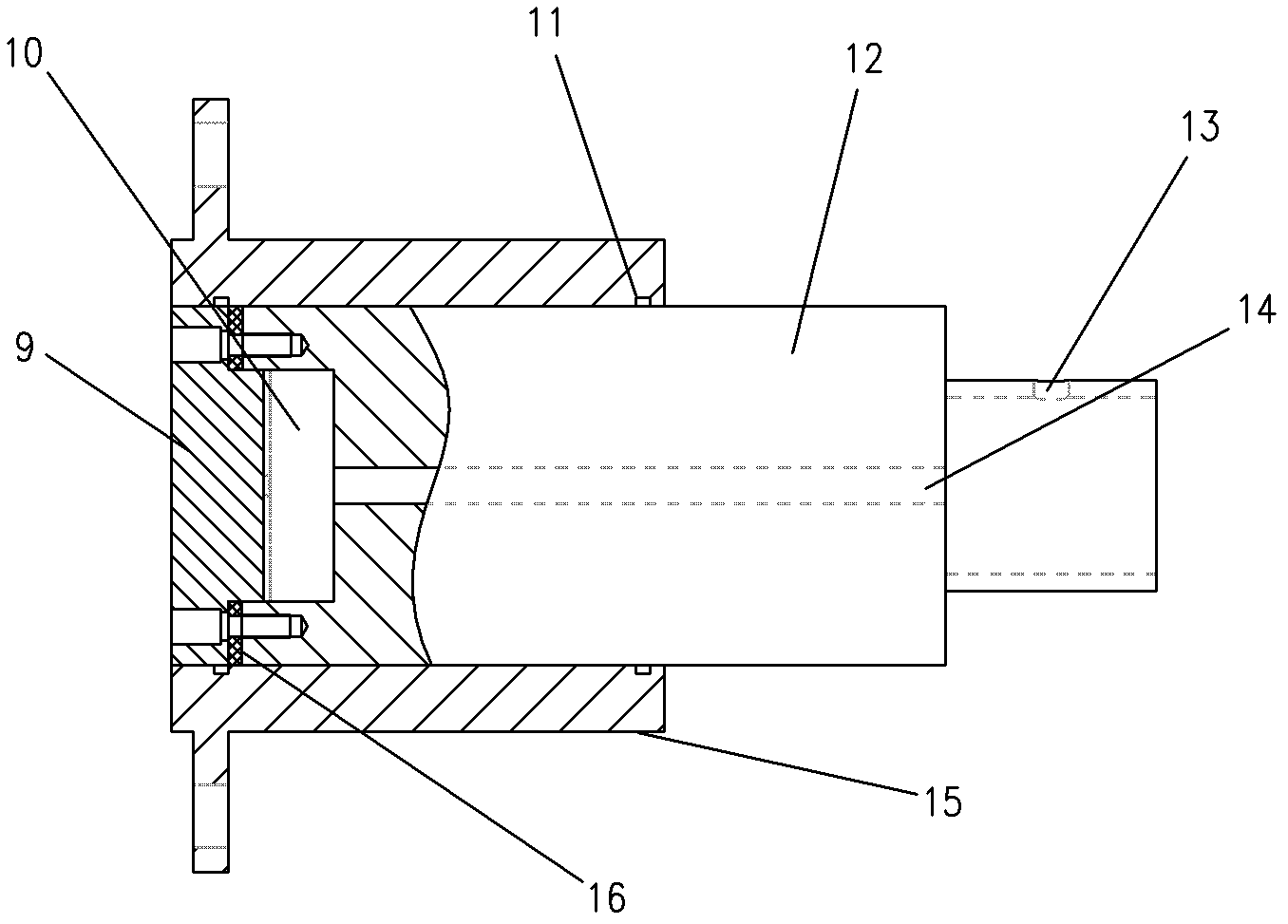

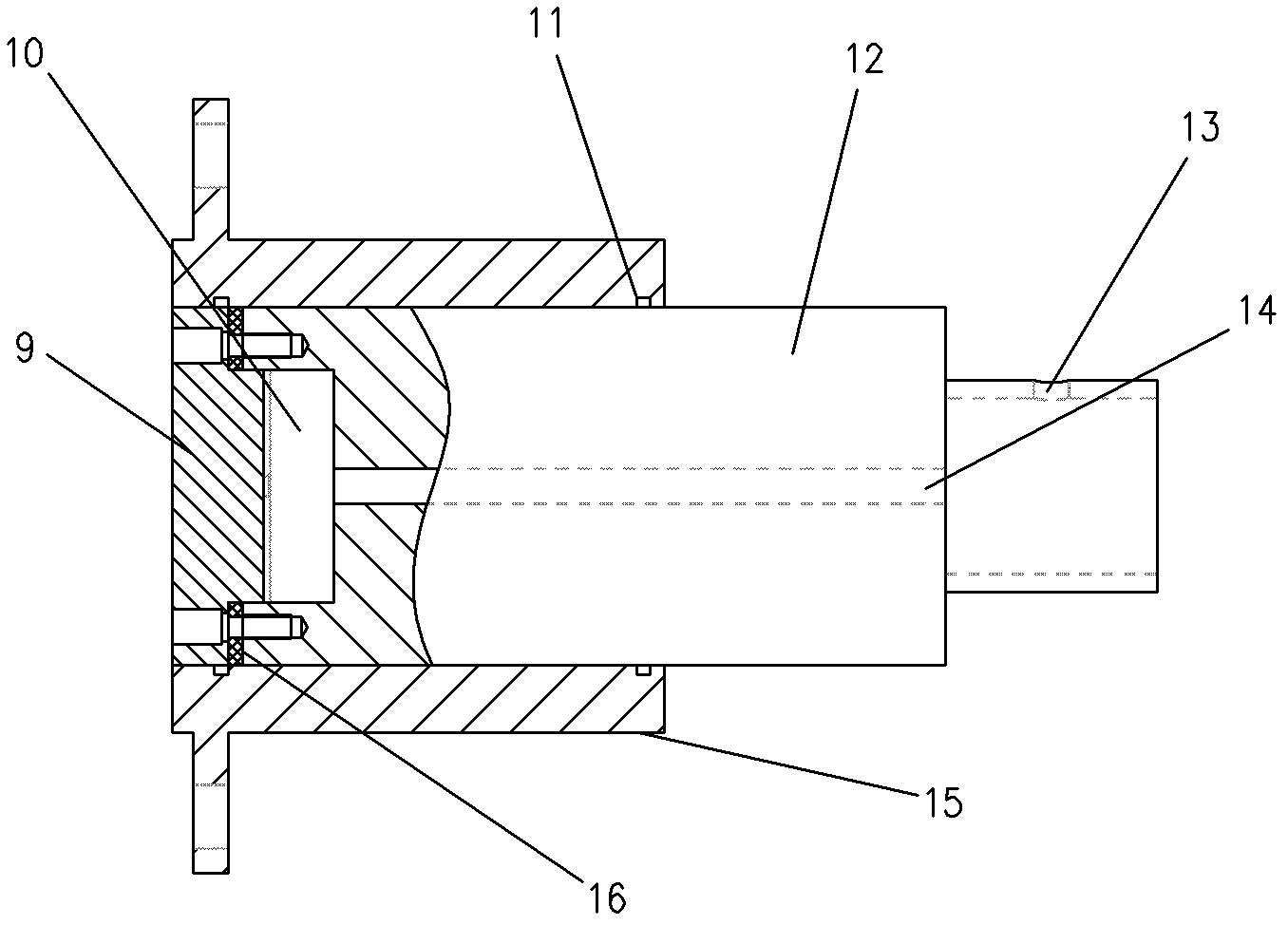

[0024] refer to figure 1 , a concrete slump detection device of the present invention, comprising a housing 15, a detection head 9, a load cell 10, a support 12, a drive motor is also provided behind the support 12, which is not shown in the figure, and a detection circuit and The computer, the detection head 9 , the load cell 10 and the support 12 are all installed in the housing 15 . An elastic body 11 is disposed between the shell 15 and the support member 12 . The detection head 9 is provided with an elastic block 16 for elastically supporting the detection head 9 to separate the detection device from the concrete and protect the detection device. The support member 12 is provided with through holes 13 and 14 for leading out the wires of the load cell 10 .

[0025] refer to figure 1 , one end of the detection head 9 is in direct contact with the concrete to be detected, and its shape is such that it can transmit force backwards and has a limited position in the forward ...

Embodiment 2

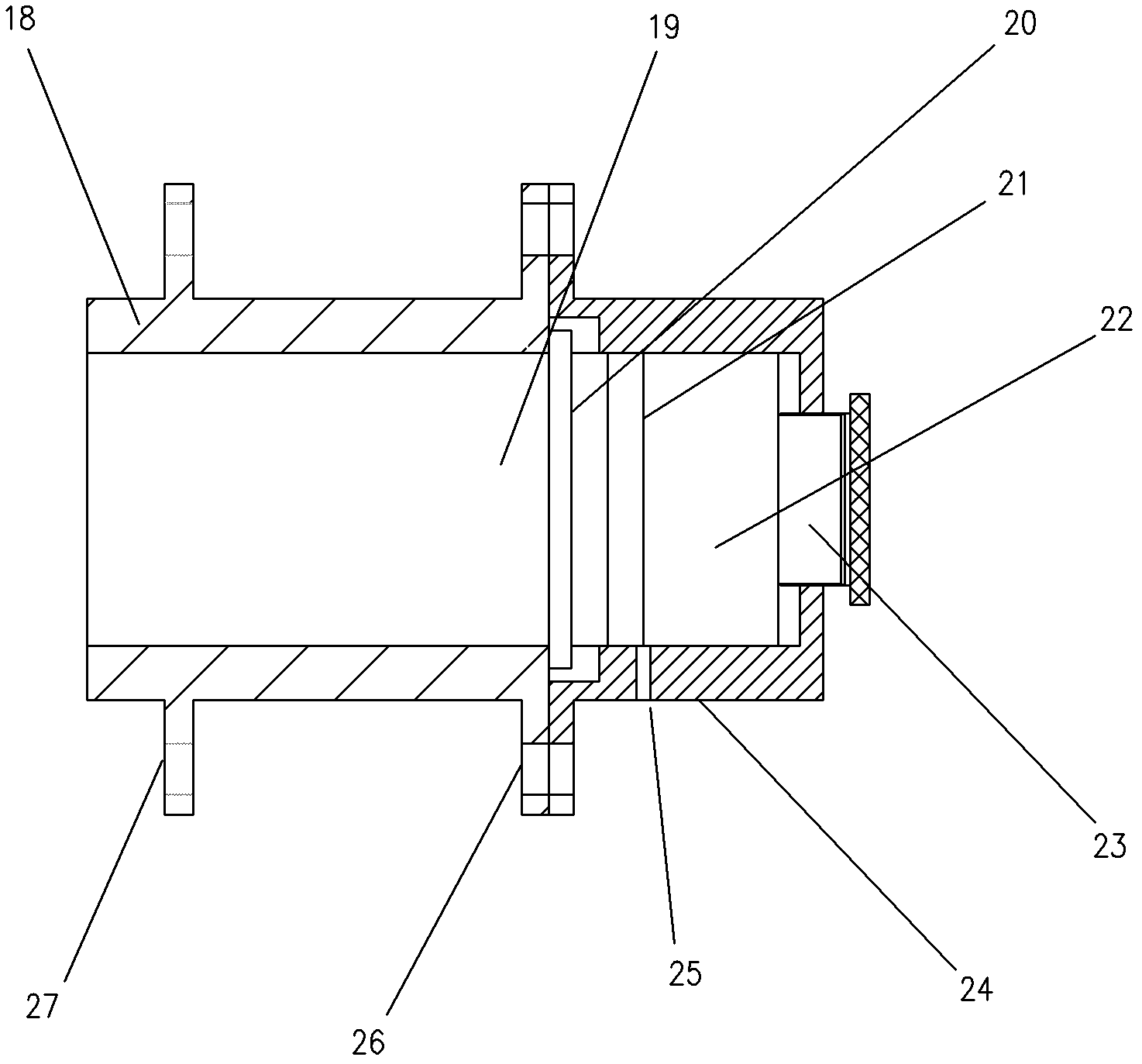

[0028] refer to figure 2 , A concrete slump detection device of the present invention includes a front housing 18, a rear housing 24, a detection head 19, a load cell 21, a support member 22, a handwheel 23, a detection circuit and a computer. One end of the detection head 19 is in direct contact with the concrete to be detected, and its shape is such that it can transmit force backwards and has a limited step 20 in the direction of forward contact with the concrete for force transmission. The other end is connected with the load cell 21 to apply force to the test On the force sensor 21, a support member 22 is provided at the rear end of the force sensor 21, and the support member 22 applies a preload through the hand wheel 23, and the hand wheel 23 is connected with the rear shell 24 through threads; the rear shell 24 and the front shell 18 are used through bolt holes 26 The bolts are connected to each other, and are fixedly connected to the mixing cylinder through the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com