Automatic bean sprout watering device

A watering device and technology of bean sprouts, applied in botany equipment and methods, soilless cultivation, cultivation, etc., can solve the problems of dry bean sprouts, difficulty in watering, affecting the color and fragrance of bean sprouts, and reduce labor intensity and workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

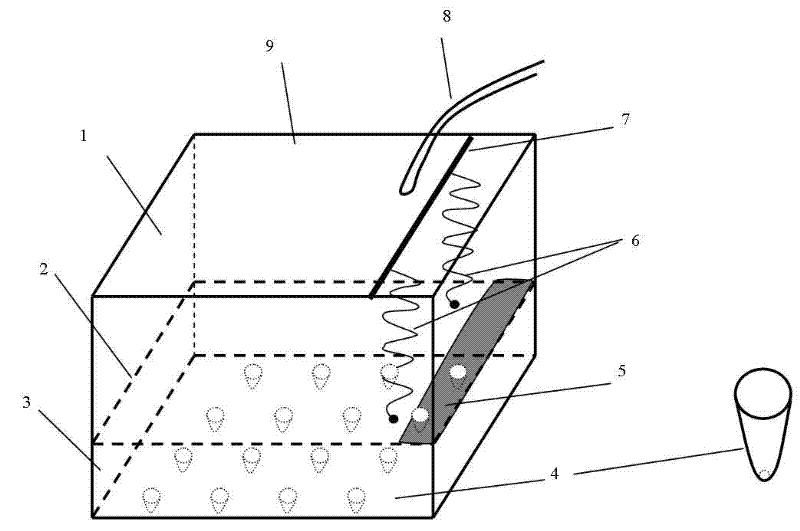

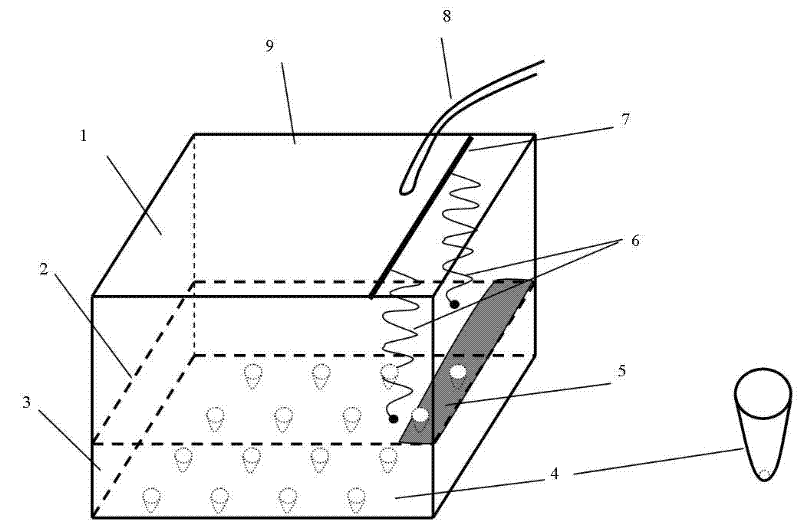

[0008] specific implementation plan

[0009] A water tank (9) is divided into an upper part (1) and a lower part (3), and it is suggested that the volume of the upper part is slightly larger than that of the lower part. A thin rod (7) fixes two springs (6), the springs pull the water tank partition (2), one end of the water tank partition (2) is fixed and can rotate, and the other end is wrapped with an iron piece, and the iron piece is fixed by a permanent magnet (5) Attraction, the plastic gasket is used to seal around the partition of the water tank to ensure that the water in the upper part of the water tank will not leak to the lower part.

[0010] The running water pipe (8) is a plastic hose, and the size of the water pipe controls the size of the incoming water. If the volume of the water tank is about 10 liters, the diameter of the water pipe is suggested to be 1mm. Water is continuously injected into the upper part of the water tank, and continuously gives a downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com