Vertical farm

A technology for farms and nutrient solutions, applied in the field of vertical agriculture, can solve the problems of inability to recycle water resources, inaccurate watering control, and unfavorable plant growth, and achieve the effects of convenient transportation nearby, conducive to growth, and water conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

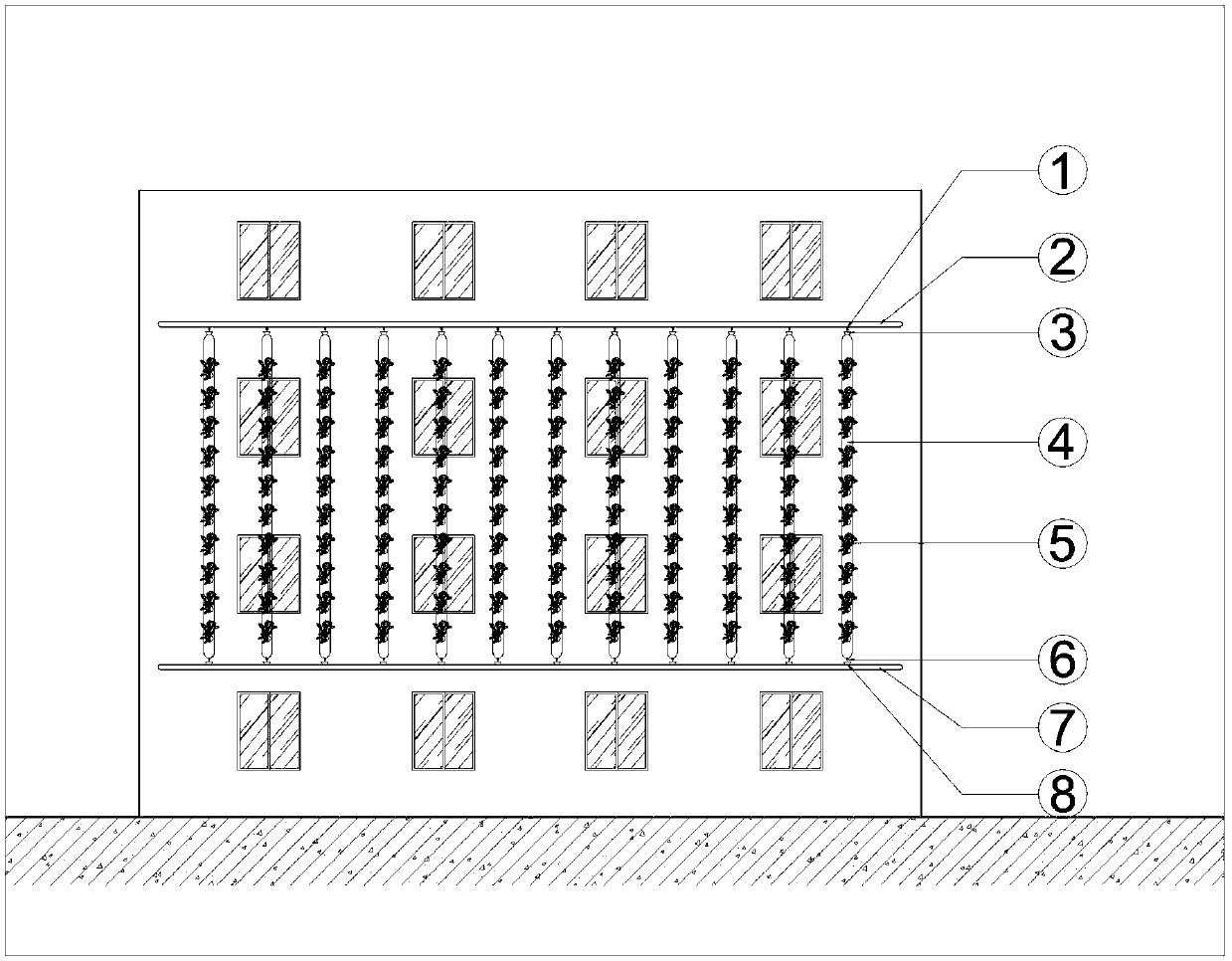

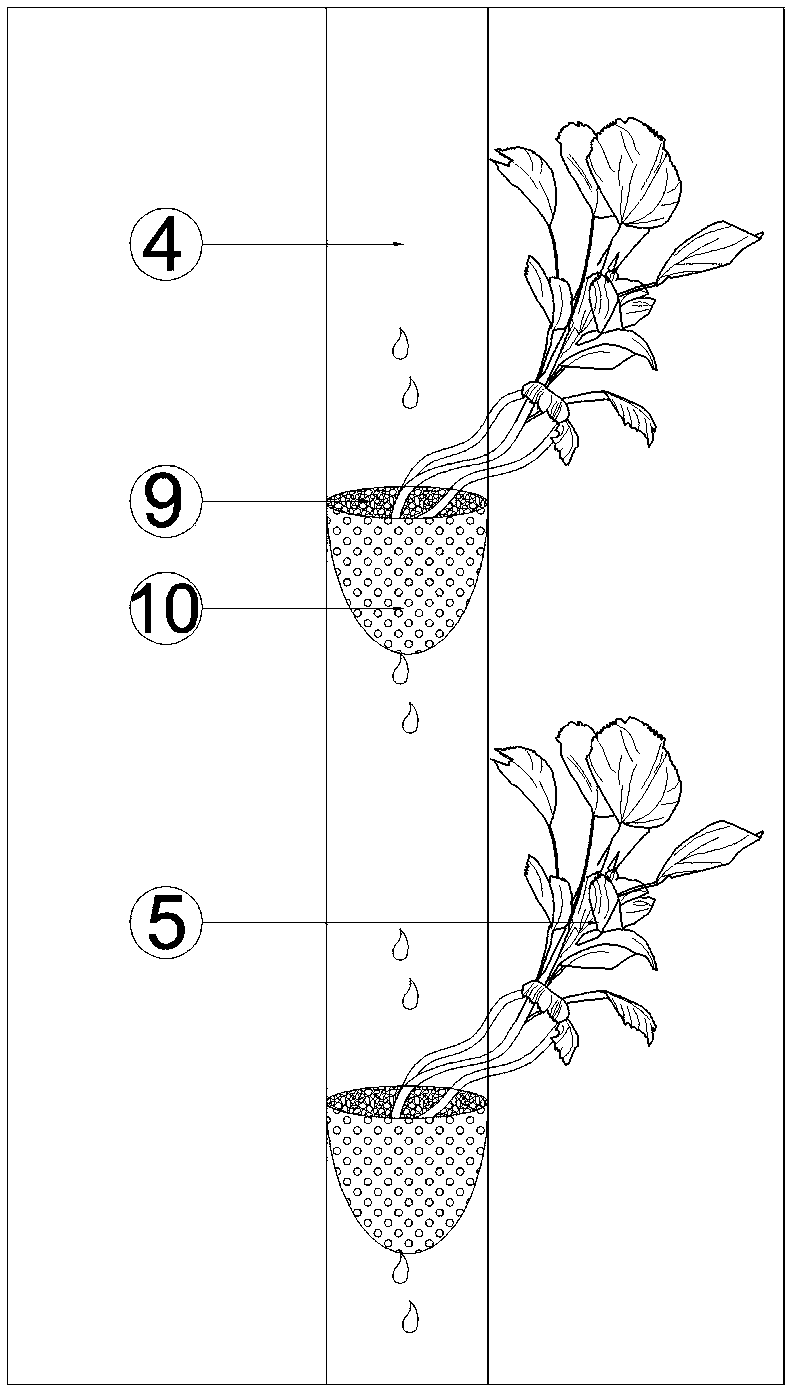

[0020] as attached figure 1 Shown: the nutrient solution enters the supply funnel 3 from the nutrient solution supply pipeline 2 through the nutrient solution nozzle 1, and flows through the vertical planting pipeline 4 to irrigate the cultivation substrate 9, and the excess nutrient solution will flow from the nutrient solution outlet 6 at the lower end to the recovery funnel 8 Collect to the nutrient solution recovery pipeline 7 to recover the nutrient solution.

[0021] The nutrient solution circulates evenly in the system to ensure the stability and health of the vertical farm.

[0022] The above are only preferred embodiments of the present invention, and are not intended to limit the present invention in any form. Any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention still belong to the present invention. within the scope of the technical solution of the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com