Double-compression roller structure for label delivering machine

A technology of double pressure rollers and pressure rollers, which is applied in the direction of labels, labeling machines, packaging, etc., can solve problems such as the trouble of threading labels 22, the label channel is not open, and the label backing paper 21 is easy to be pulled off, etc., and achieves ingenious design , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

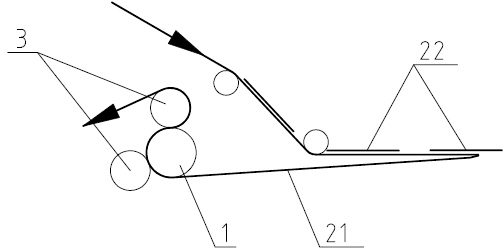

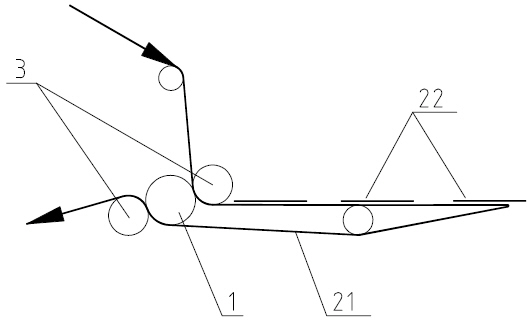

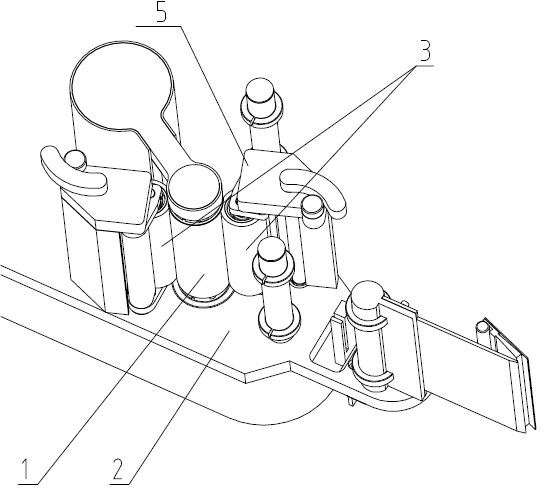

[0026] The structure diagram of the present invention is as figure 2 , 3 As shown, the double pressure roller structure used for the label feeder of the present invention includes a driving roller 1 installed on the main board 2 of the label feeder and two groups of pressure rollers 3. The two groups of pressure rollers 3 are identical in structure. The set of pressing rollers 3 are arranged on both sides of the driving roller 1, wherein the label backing paper 21 and the label 22 are pressed on the surface of the driving roller 1 by one of the pressing rollers 3, after the label 22 is separated from the label backing paper 21, the label backing paper 21 is again It bypasses the active roller 1 of the label feeder and is pressed on the surface of the active roller 1 by another pressure roller 3 .

[0027] In this embodiment, the lower end of the pressure roller 3 is installed on the main board 2 of the marking device through the lower bearing 32, and the upper end of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com