58-core composite cable

A technology of integrated cables and cable cores, applied in the direction of insulated cables, flexible cables, cables, etc., can solve the problems of low transmission rate, poor mechanical and physical properties of ethylene-propylene rubber insulation, and inability to guarantee signal integrity, etc., and achieve low hardness , Guarantee the effect of insulation heat shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

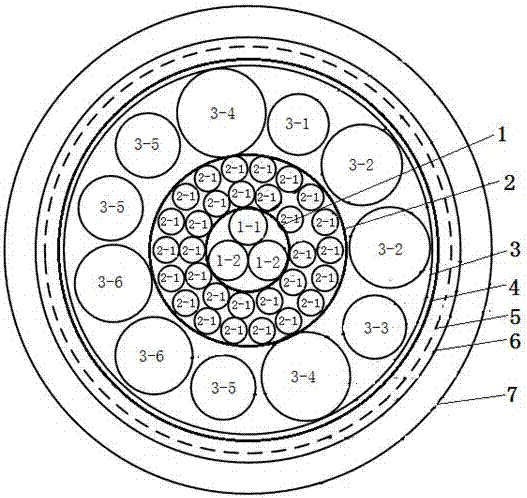

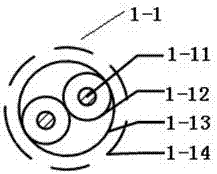

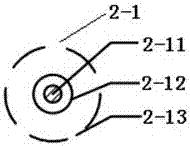

[0020] like Figure 1 to Figure 9 As shown, a 58-core integrated cable, using a 0.35mm 2 The twisted-pair shielded wire 1-1 and the two 1553B data buses 1-2 are twisted into a bundle to form a cable core I1, and 12 0.35mm cables are arranged in sequence outside the cable core I1 2 Shielded single wire 2-1 and 18 0.35mm 2 The shielded single wire 2-1 is bundled to form the cable core II2, and a 1.5mm 1.5mm line is arranged clockwise outside the cable core II2. 2 Twisted pair 3-1, two 2.5mm 2 3-2 twisted pairs, one 1.2mm 2 3-3 twisted pairs, one 3.0mm 2 3-4 twisted pairs, one 1.2mm 2 Twisted pair shielded wire 3-5, two 2.0mm 2 Twisted pair shielded wire 3-6, two 1.2mm 2 Twisted pair shielded wire 3-5, one 3.0mm 2 The twisted pairs 3-4 are bundled to form a cable core III3, and a layer of flame-retardant isolation layer I4, a layer of general shielding layer 5, a layer of flame-retardant isolation layer II6, and a layer of sheath 7 are arranged in sequence outside the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com