Broken yarn pneumatic processing device of ring spinner

A ring spinning machine and processing device technology, applied in textiles and papermaking, etc., can solve problems such as inconvenient operation, inconvenient operation, and defective detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

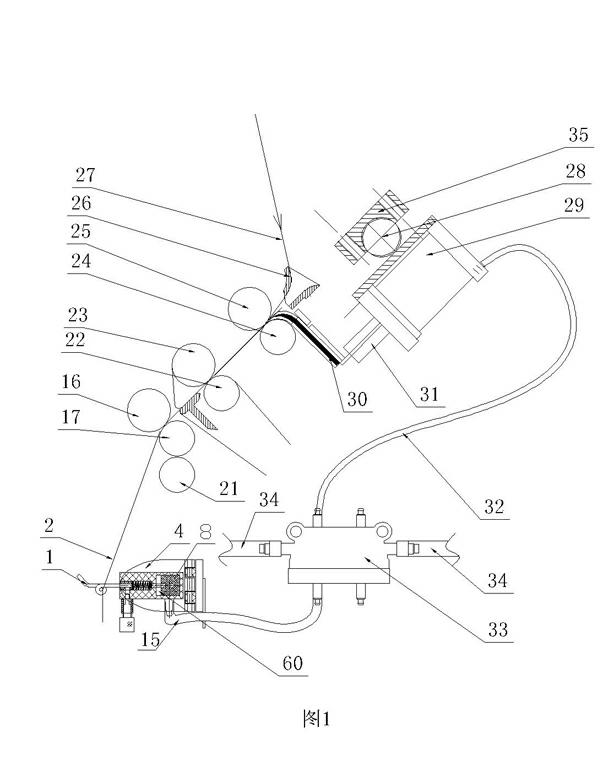

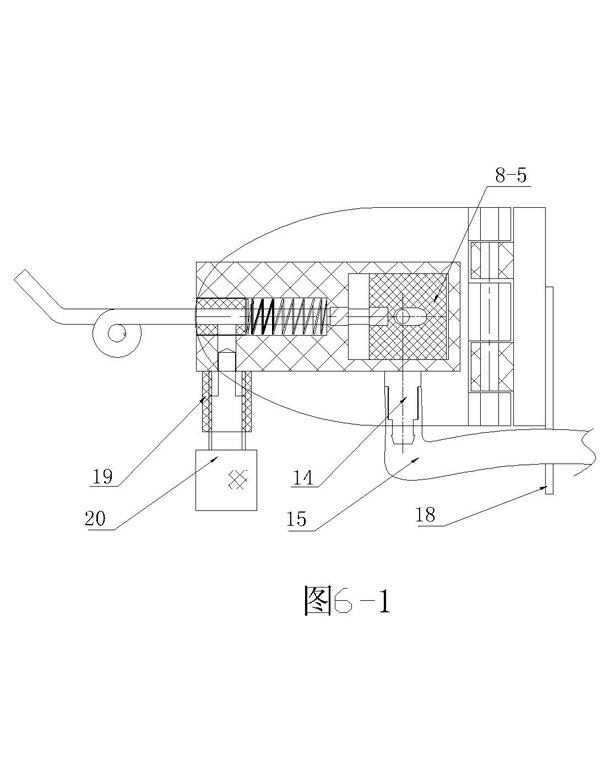

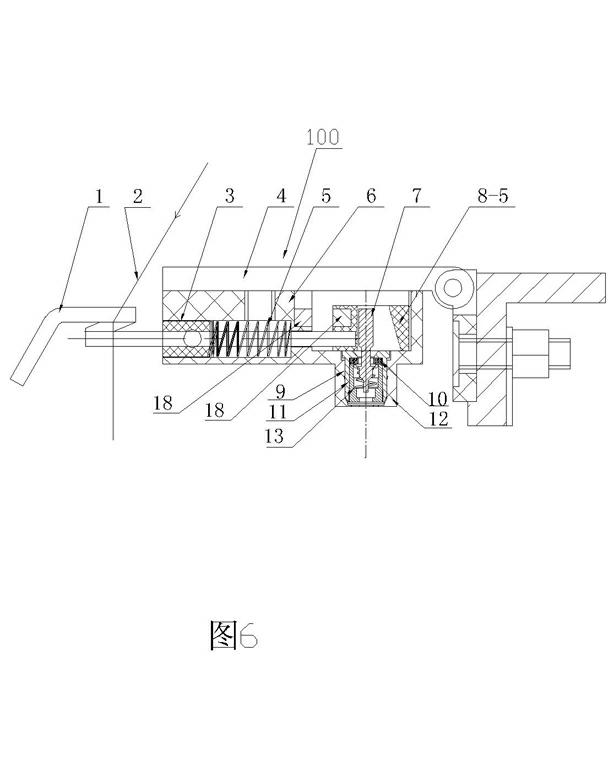

[0034] Such as figure 1 As shown, it is a schematic diagram of the operation of the pneumatic processing device for broken yarn on the ring spinning machine of the present invention when the yarn is guided. Such as figure 2 , diagram 2-1 Shown is a schematic structural view and a top view of the gas valve switch in the embodiment of the present invention.

[0035] In the ring spinning machine, the roving 27 enters the holding area formed by the rear roller 24 and the rear top roller 25 through the yarn guide 26, and guides the holding area between the middle roller 22 and the middle top roller 23, and then guides the front The gripping area between the roller 17 and the front top roller 16 forms the yarn 2 after multi-pass drafting and twisting, and the yarn guide hook 1 is installed under the front roller 17 and the front top roller 16. The above structure is a common technology in the field of ring spinning machines, and will not be repeated here.

[0036] The broken y...

Embodiment 2

[0048] Such as image 3 , Figure 3-1 As shown, the structure and working principle are the same as in Embodiment 1, the difference is that the inside of the limit block is wedge-shaped, the slope faces to the left, a pair of magnetic devices are formed, and the trachea faces downward.

Embodiment 3

[0050] Such as Figure 4 , Pic 4-1 As shown, the structure and working principle are the same as in Embodiment 1, the difference is that the inside of the limit block is ring-shaped, two sets of paired magnetic devices, and the trachea faces to the right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com