Temperature-sensitive printing color paste and color-temperature clothing

A printing color paste and printing technology, which is applied in the field of temperature-sensitive printing color paste and temperature-sensitive color-changing clothing, can solve the problems of printing color paste color stability to be improved, color change insensitivity, etc., to improve permeability and sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

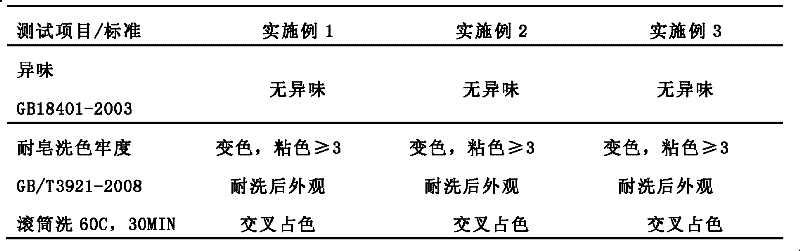

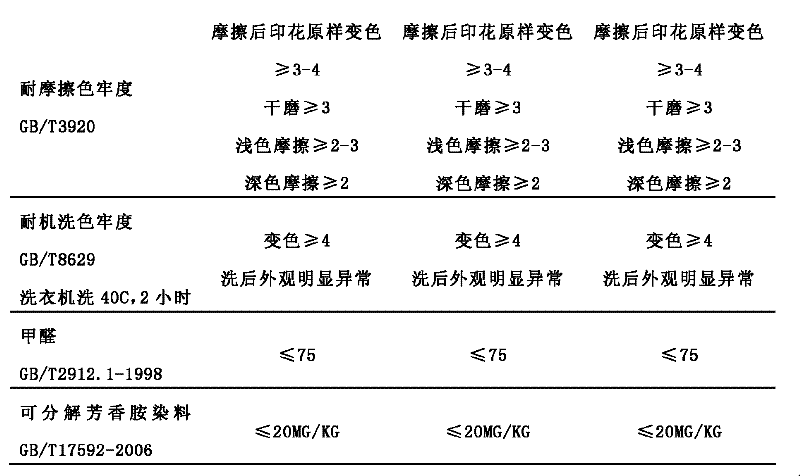

Examples

Embodiment 1

[0046] Weigh 80 kg and 17 kg of printing white paste and printing transparent paste, add the printing white paste and printing transparent paste into a mixer, mix and stir evenly, and set the stirring speed to 800 rpm. After stirring evenly, continue to add 2kg of temperature-sensitive pigment into the mixer, and after stirring evenly, add 1kg of fastening agent into the mixer to obtain a temperature-sensitive printing color paste.

Embodiment 2

[0048] Weigh 82 kg and 15.5 kg of printing white paste and printing transparent paste, add the printing white paste and printing transparent paste into a mixer and mix evenly, and set the stirring speed to 700 rpm. After stirring evenly, continue to add 1.5 kg of temperature-sensitive pigment into the mixer, and after stirring evenly, add 1 kg of fastening agent into the mixer to obtain a temperature-sensitive printing color paste.

Embodiment 3

[0050] Weigh 79 kg and 17.2 kg of printing white paste and printing transparent paste, add the printing white paste and printing transparent paste into a mixer and mix evenly, and set the stirring speed to 800 rpm. After stirring evenly, continue to add 2.8kg of temperature-sensitive pigment into the mixer, and after stirring evenly, add 1kg of fastening agent into the mixer to obtain a temperature-sensitive printing color paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com