Extraction guide device of drawer

A guide device and drawer technology, which is applied to drawers, furniture parts, household appliances, etc., can solve the problems of complex structure of extracting guide devices, unstable drawing process of drawers, poor stability of guide rails, etc. Smooth effect of pulling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

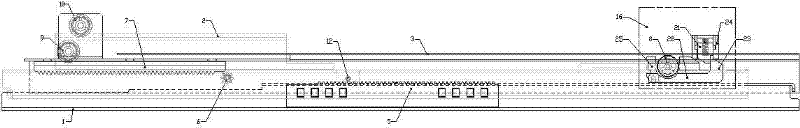

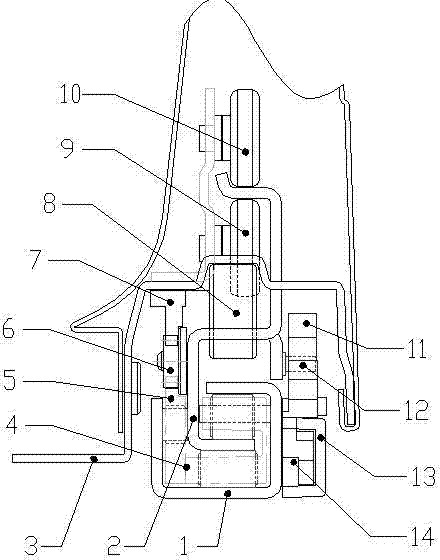

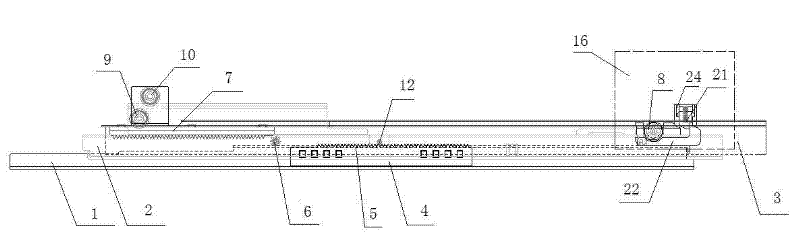

[0029] Such as Figure 1-5 As shown, the present invention includes two guide units arranged on the left and right sides of the drawer. The aforementioned guide units include the lower rail 1, the middle rail 2, the draw-out rail 3, the draw-out rail 3 and the middle slide rail which are buckled sequentially from bottom to top. 2 are provided with rollers 8, 9, 10, and the rollers 8, 9, 10 transmit the load between the guide rails; at least one of the middle slide rails 2 of the guide unit is provided with a connecting device 16, with the help of the connecting device 16, when the drawer is about to close At the same time, the middle slide rail 2 and the draw-out rail 3 can be connected at the ends of their sliding paths; the buckle between the middle slide rail 2 and the lower slide rail 3 is provided with a b-shaped ball seat 4, and the balls on the ball seat 4 To f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com