LED (Light Emitting Diode) lamp tube

A technology for LED lamps and lamps, applied in the field of LED lamps, can solve the problems of high manufacturing cost and low manufacturing efficiency, and achieve the effect of improving manufacturing efficiency and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

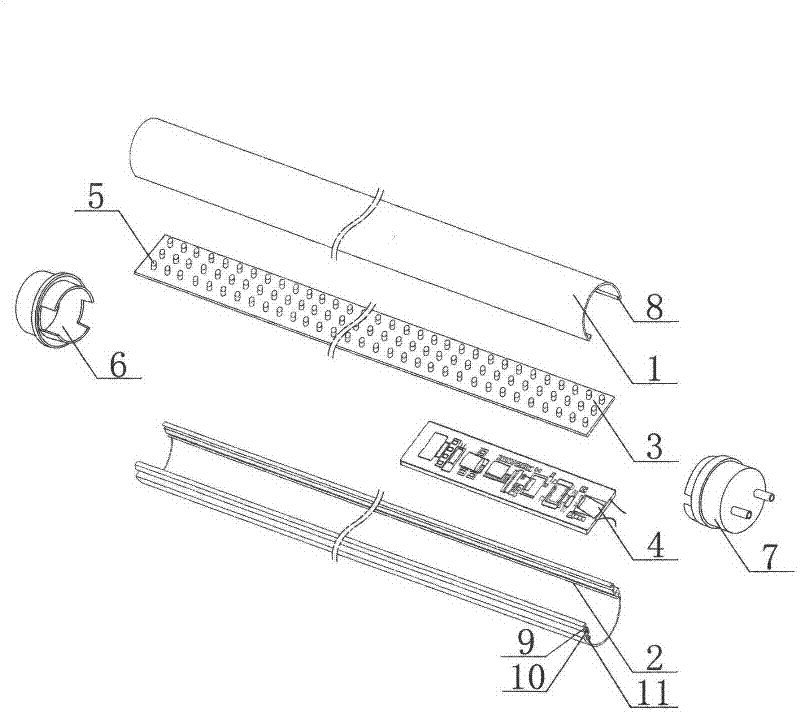

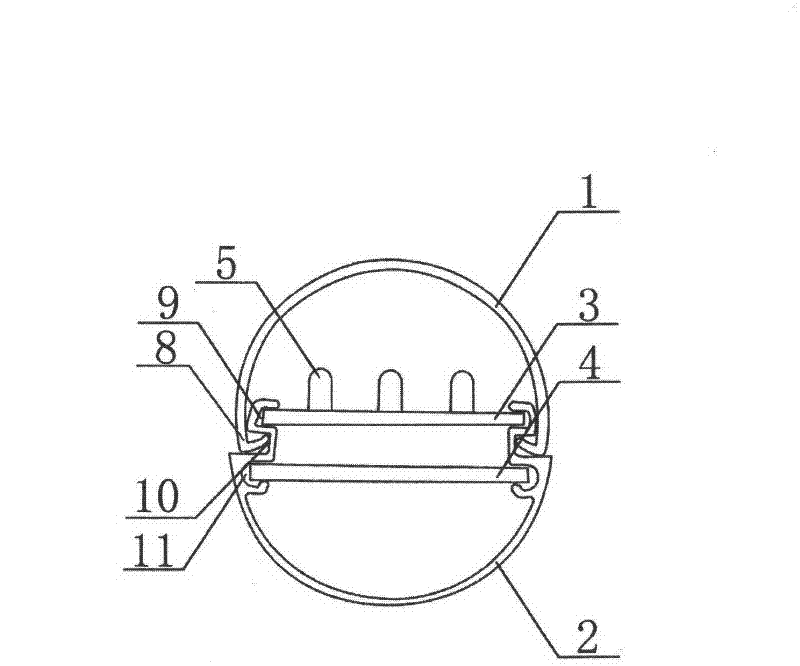

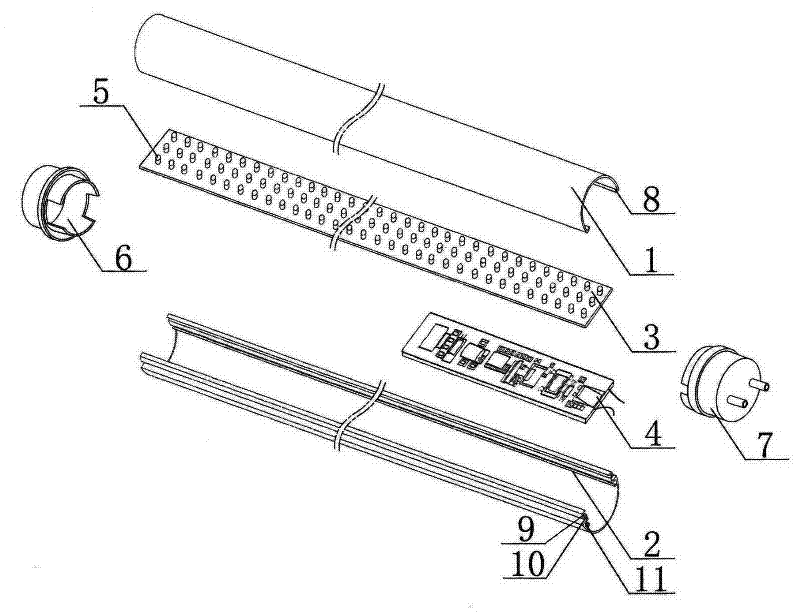

[0012] See figure 1 , figure 2 As shown, the present invention provides an LED lamp tube, which includes a lampshade 1, a load-carrying lamp board 3, a driving power supply 4, a lamp holder 2, a left end cover 6 and a right end cover 7. The lamp shade 1 and the lamp holder 2 are in a semicircle shape. The inner wall of the lampshade 1 is provided with a barb 8, and the inner wall of the lamp holder is provided with a card slot I, a card slot II, and a card slot III. The barb 8 is embedded in the card slot II 10 so that the lamp shade 1 and the lamp holder 2 are tightly connected to each other to form a circle. Shaped lamp tube, an accommodating space is formed in the inner hole of the circular lamp tube, a load-carrying lamp board 3 and a driving power supply 4 are arranged in the accommodating space, and the left end cap 6 and the right end cap 7 are embedded into the inner walls of both ends of the lamp tube.

[0013] Wherein, the lamp carrying board 3 is inserted into the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap