Pulverized coal burner

A burner, pulverized coal technology, applied in burners, burners burning powder fuel, combustion methods, etc., can solve problems such as shedding, furnace negative pressure fluctuations, affecting the stable operation of burners, etc., to promote ignition and stable combustion. , the effect of increasing the mixing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

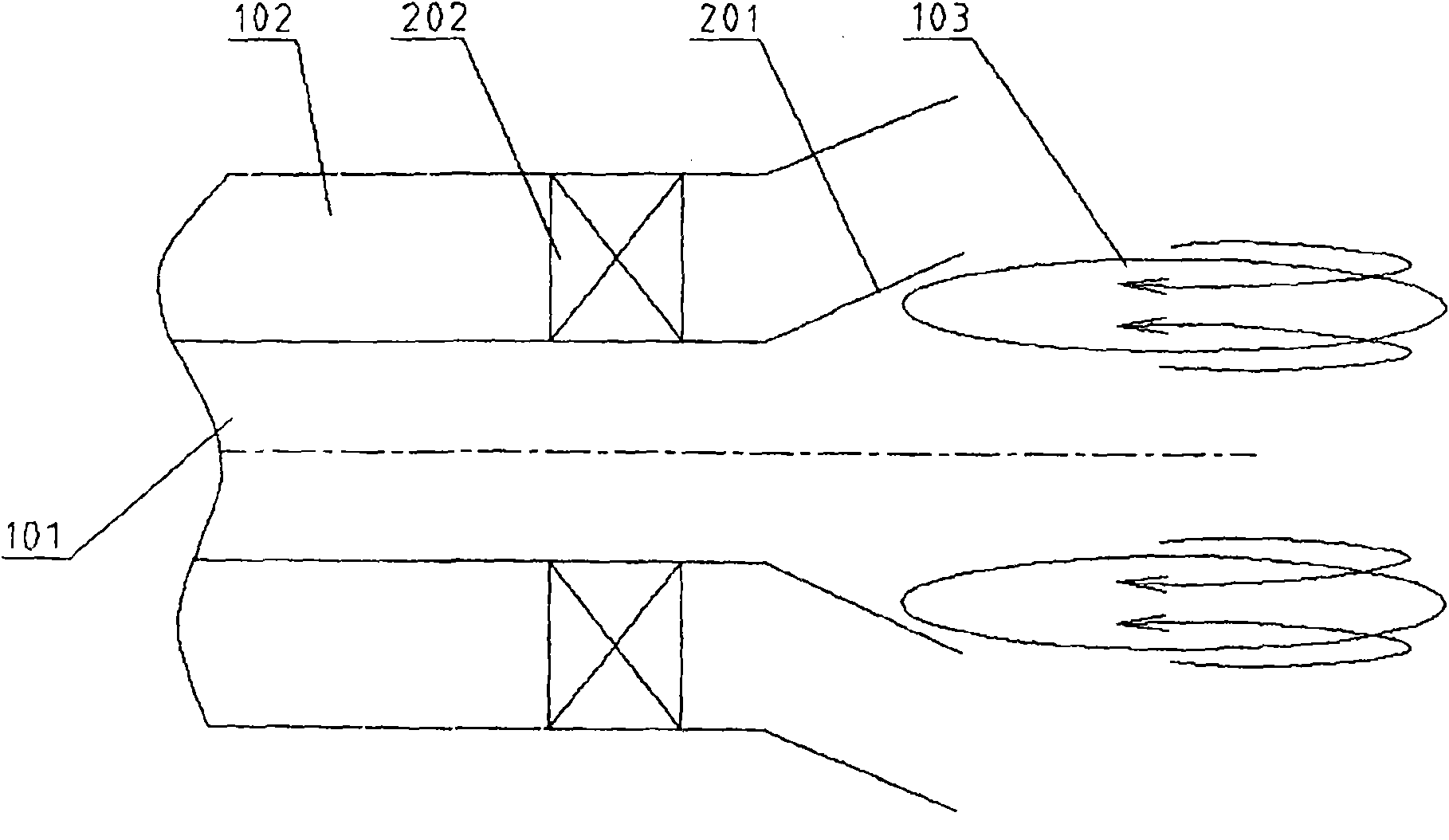

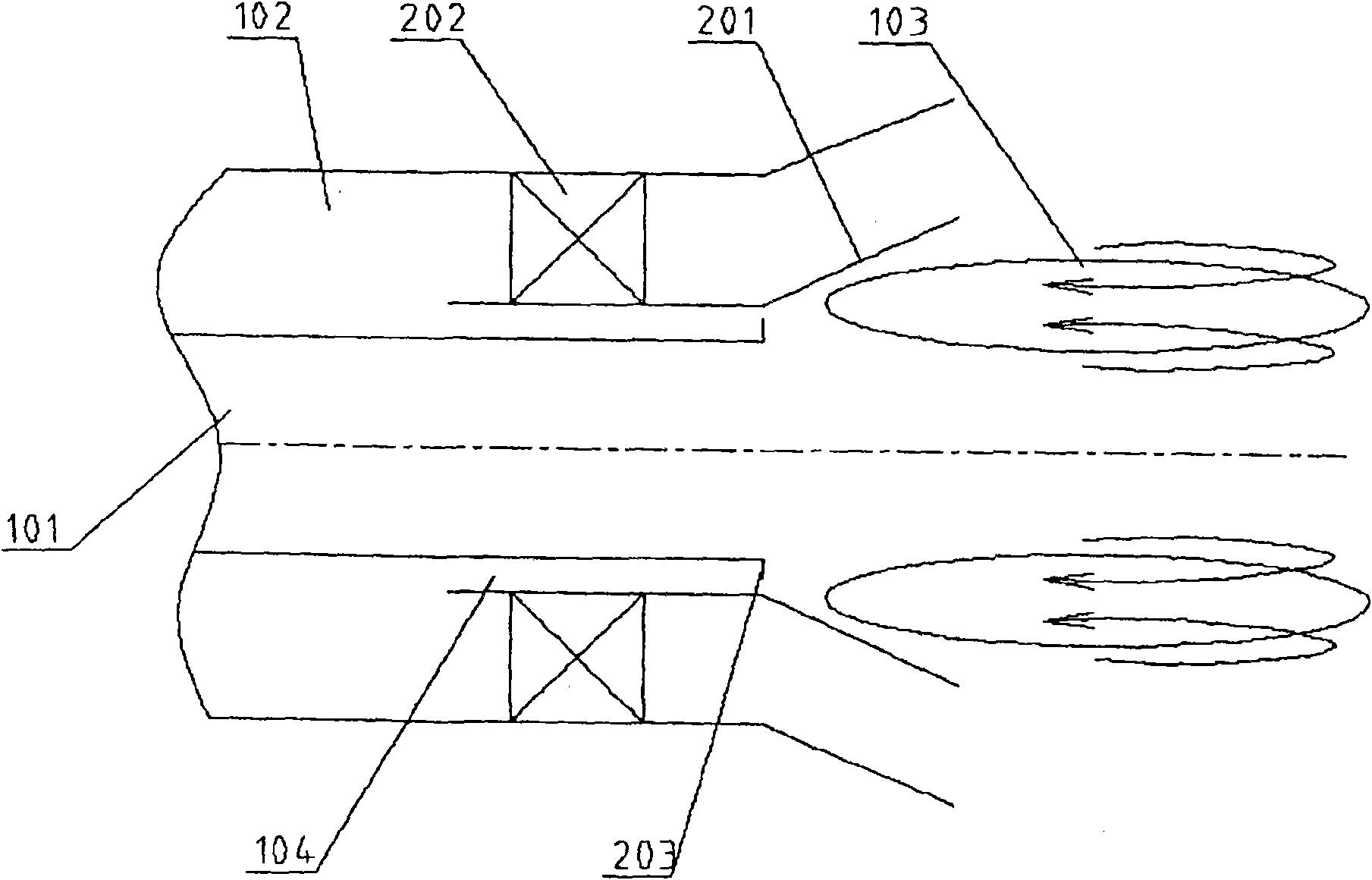

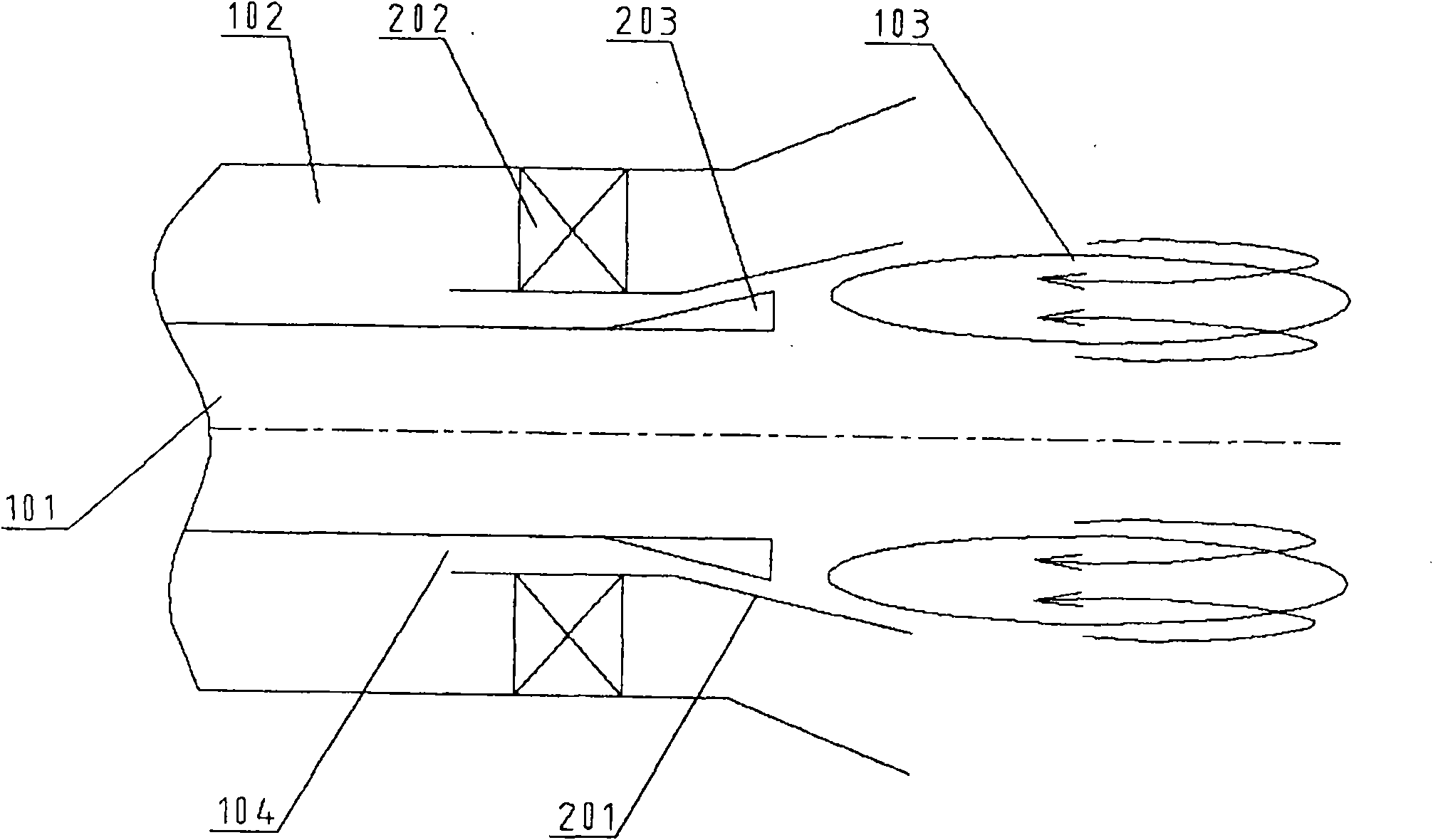

[0023] figure 1 It is a burner with an expanding cone-shaped pulverized coal nozzle and its flow field distribution diagram in the prior art. The primary air pulverized coal airflow passes through the pulverized coal airflow channel 101 and enters the furnace from the inner side of the pulverized coal nozzle 201 . The pulverized coal nozzle 201 is in the shape of an expanded cone, and the flow area along the direction of the pulverized coal airflow gradually increases. A secondary air passage 102 is arranged around the pulverized coal air passage (primary air passage) 101 for sending combustion-supporting air into the furnace. A secondary air swirling device 202 is usually provided in the secondary air channel 102 to rotate the secondary air flow. When the secondary air flow passes through the outer surface of the pulverized coal nozzle 201, the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com