Evaporator for solid-liquid separation

A technology of solid-liquid separation and evaporator, which is applied in the direction of evaporation, separation methods, chemical instruments and methods, etc. It can solve the problems of high value-added loss, affecting normal production, solidification of residues, etc., and achieves large cross-sectional area and good sealing performance , the effect of short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

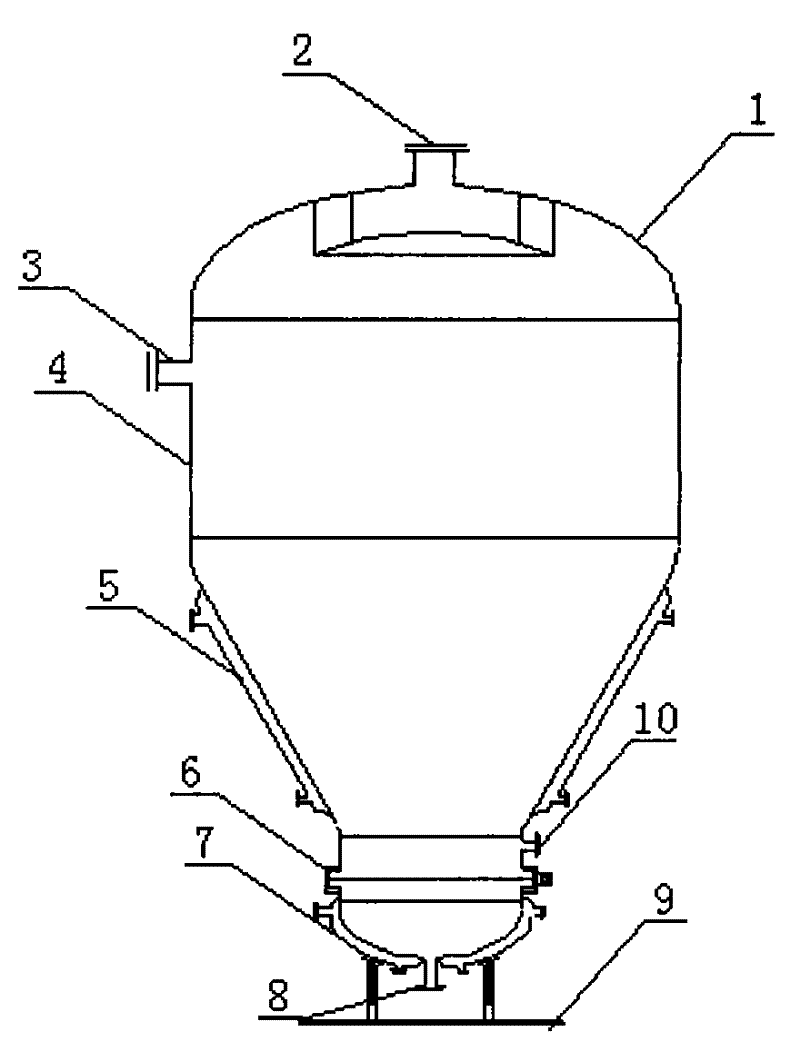

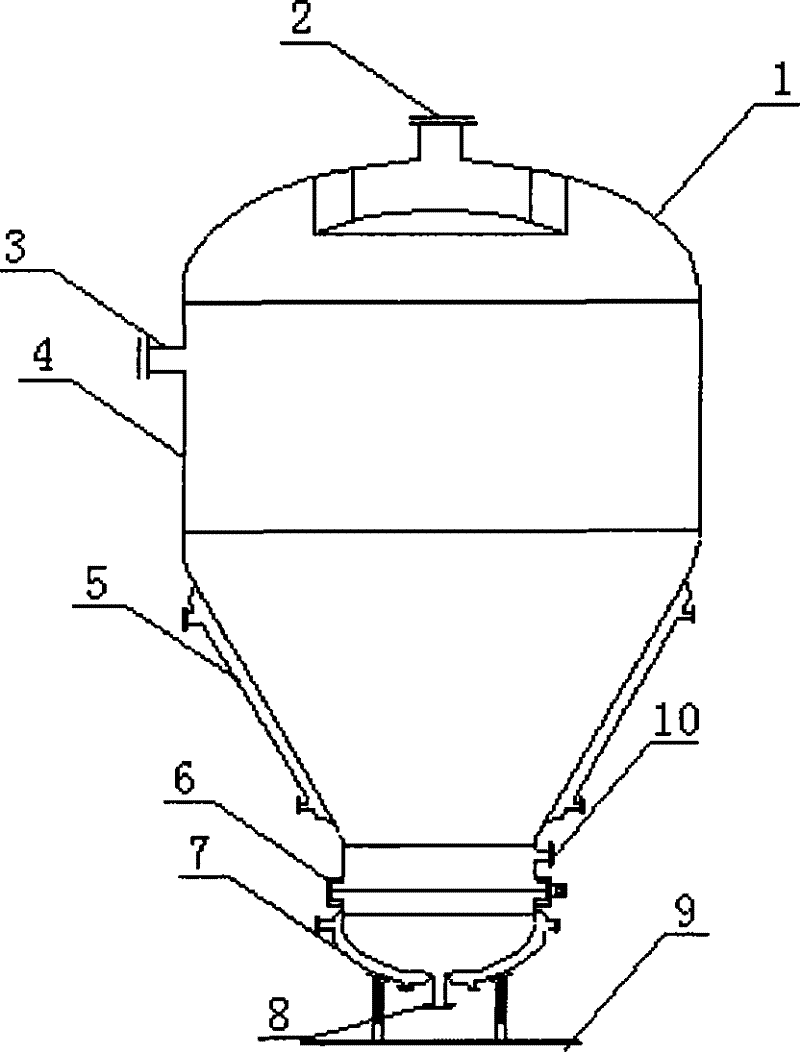

[0012] figure 1 It is a structural schematic diagram of the present invention. As can be seen from the figure, a solid-liquid separation evaporator includes an upper head 1, an upper cylinder 4, a conical cylinder 5 and a bottom cover 7 connected sequentially from top to bottom, and is characterized in that the inner diameter of the upper cylinder 4 Far larger than the inner diameter of the bottom cover 7, forming a shape with a large top and a small bottom; the conical cylinder 5 and the bottom cover 7 are connected by a quick-release locking device 6; the bottom outlet 8 is located in the center of the bottom cover 7, and the nitrogen inlet 10 is located in the conical Bottom side of barrel 5.

[0013] The quick-release locking device 6 adopts a clamp structure composed of two semicircular collars. The section of the collar is "匚" shape, and the upper and lower inner surfaces are wedge-shaped. Flange clamped. The flange sides of the tapered barrel 5 and the bottom cover 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com