Pneumatic tire for vehicles

A technology for pneumatic tires and vehicles, applied in tire measurement, vehicle parts, tire parts and other directions, can solve problems such as discomfort to the human ear, and achieve the effects of improving drainage channels, generating small noise, and reducing tire excitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

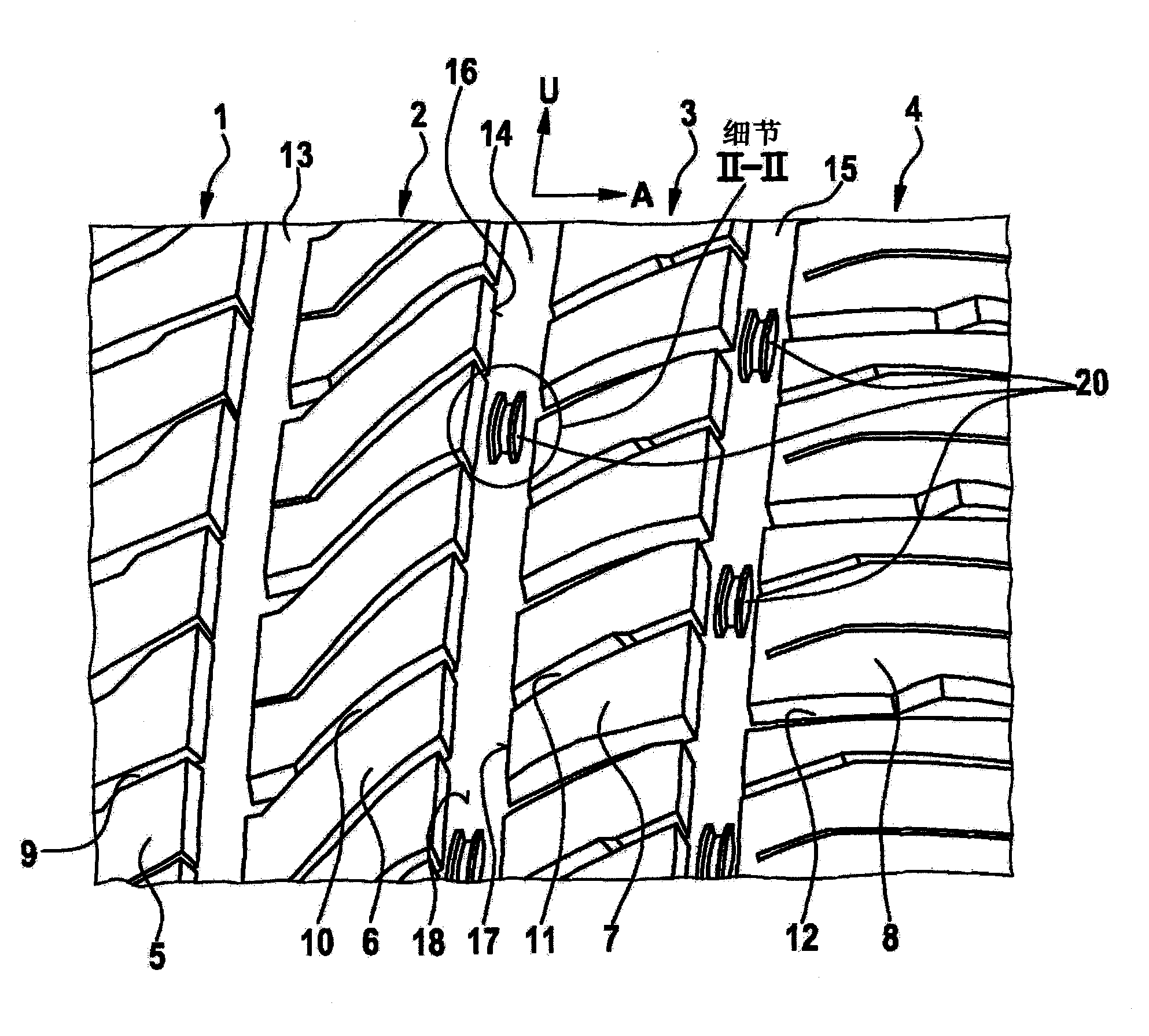

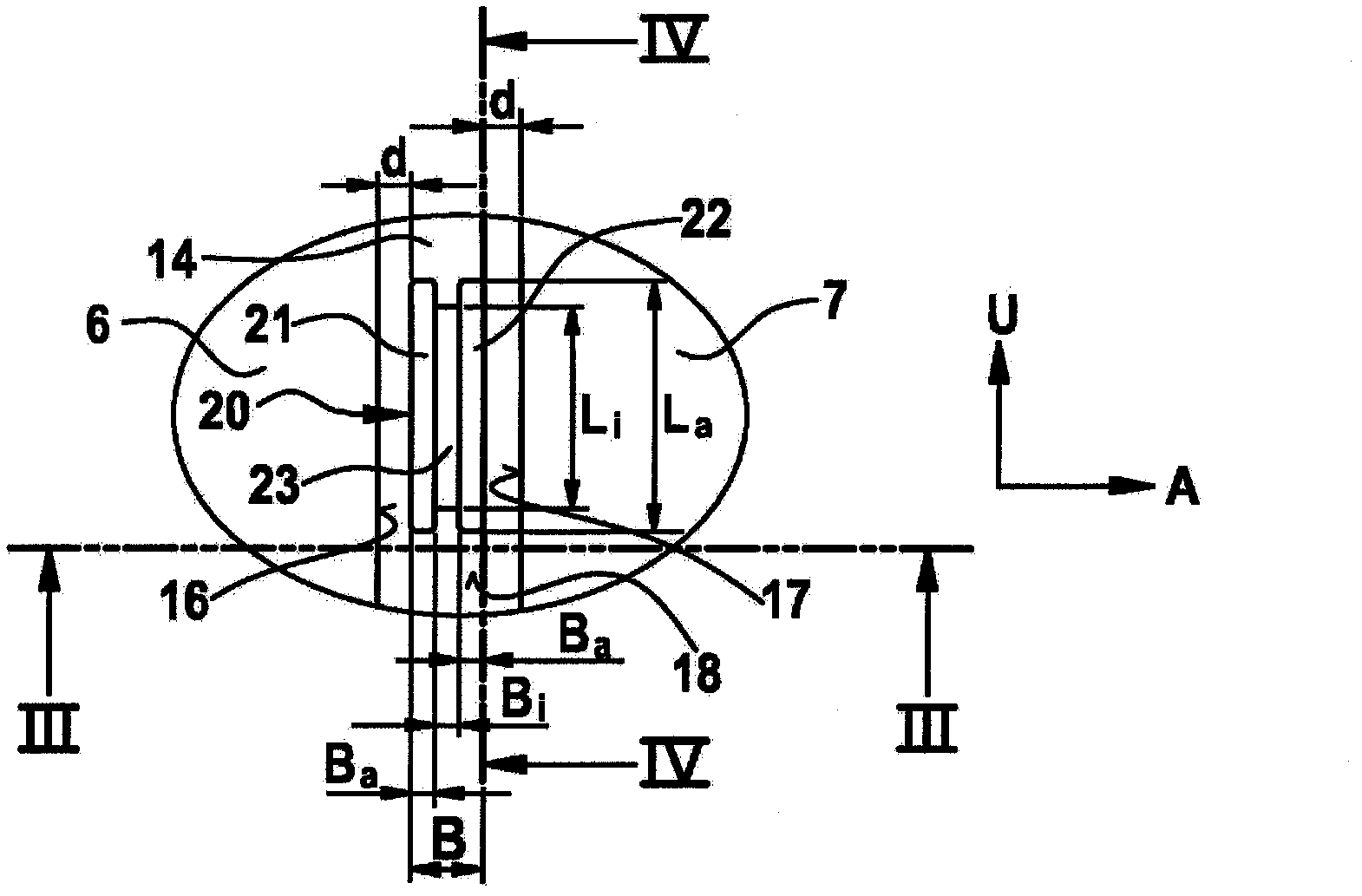

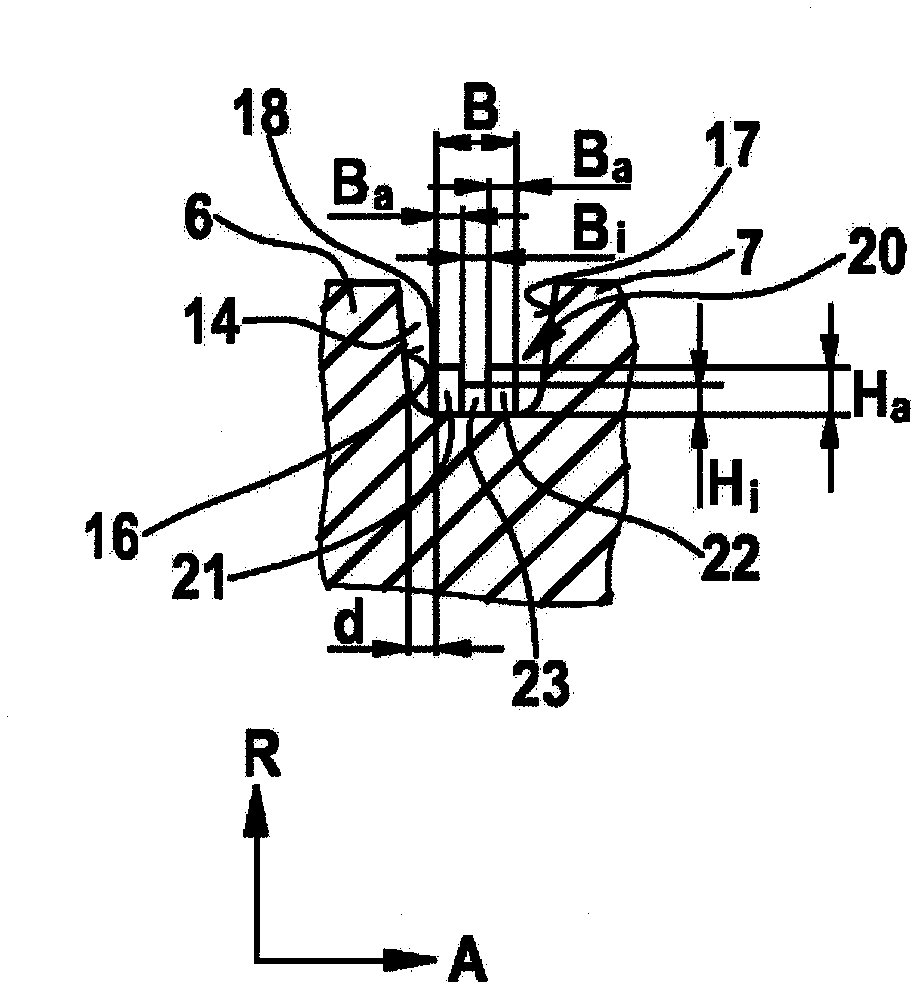

[0063] Figure 1 to Figure 4 A tread pattern of a prior art vehicle pneumatic tire for passenger cars is shown. The vehicle pneumatic tire is constructed in a known manner (not shown in detail) and has: two tire beads extending in the circumferential direction U on the circumference of the vehicle pneumatic tire; A carcass of radial construction extending upward and in the axial direction A of a pneumatic tire of a vehicle from bead to bead, the carcass having one or two layers of reinforcing fabric embedded in rubber; A buffer extending in the radial direction R of the vehicle pneumatic tire outside the carcass, in the circumferential direction U on the circumference of the vehicle pneumatic tire, and in the axial direction A of the vehicle pneumatic tire from shoulder to shoulder Belt with one or two layers of reinforcing fabric made of steel or aramid embedded in rubber; A strip with a reinforcing fabric oriented in the circumferential direction embedded in rubber so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com