Driving magnetic bearing system based on intelligent material controllable shafting radial vibration

An active magnetic bearing and intelligent material technology, applied in the electromagnetic field, can solve the problems of shell vibration, increase control difficulty, difficult position control, etc., and achieve the effect of reducing excitation, simplifying position control difficulty, and improving position control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

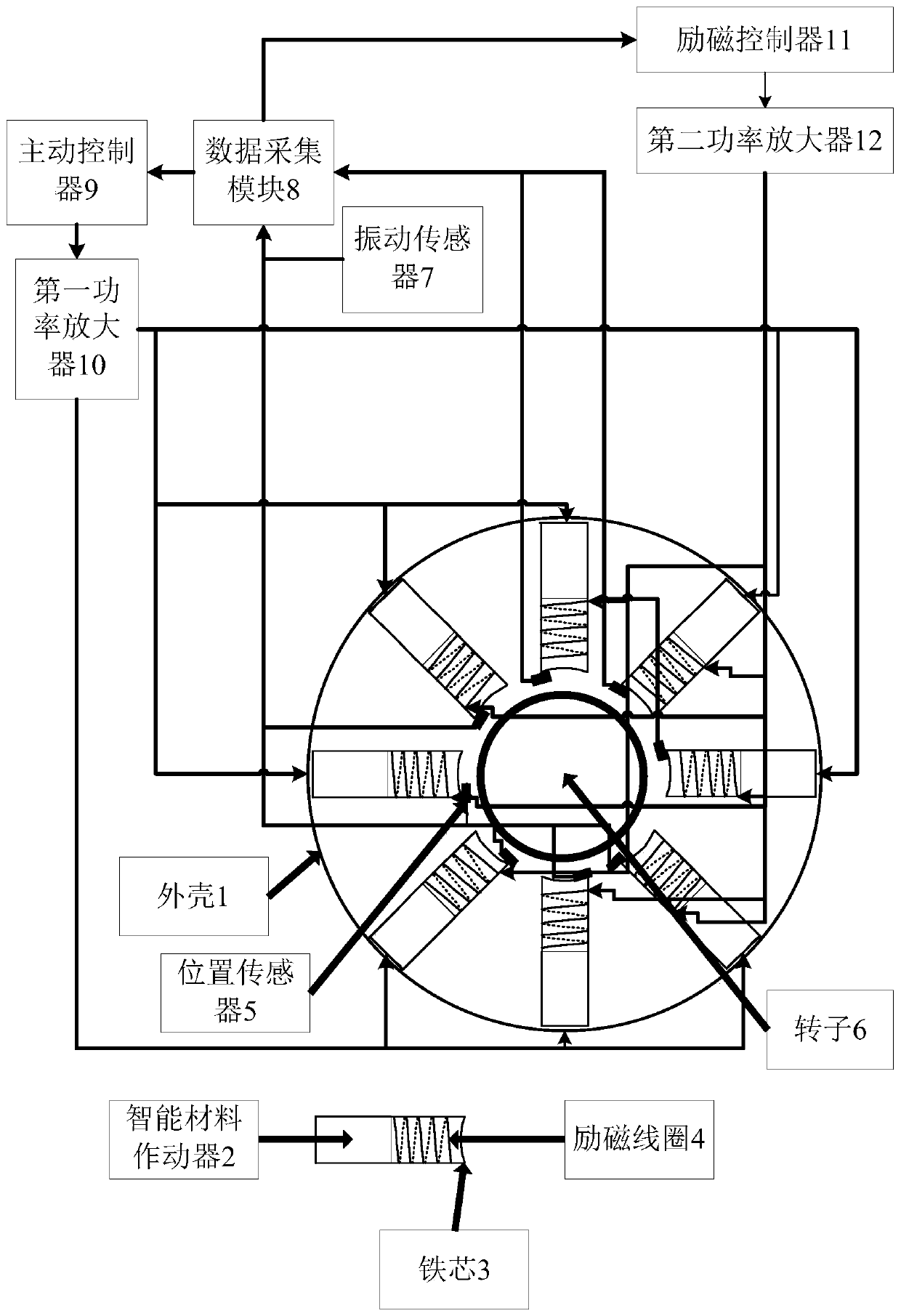

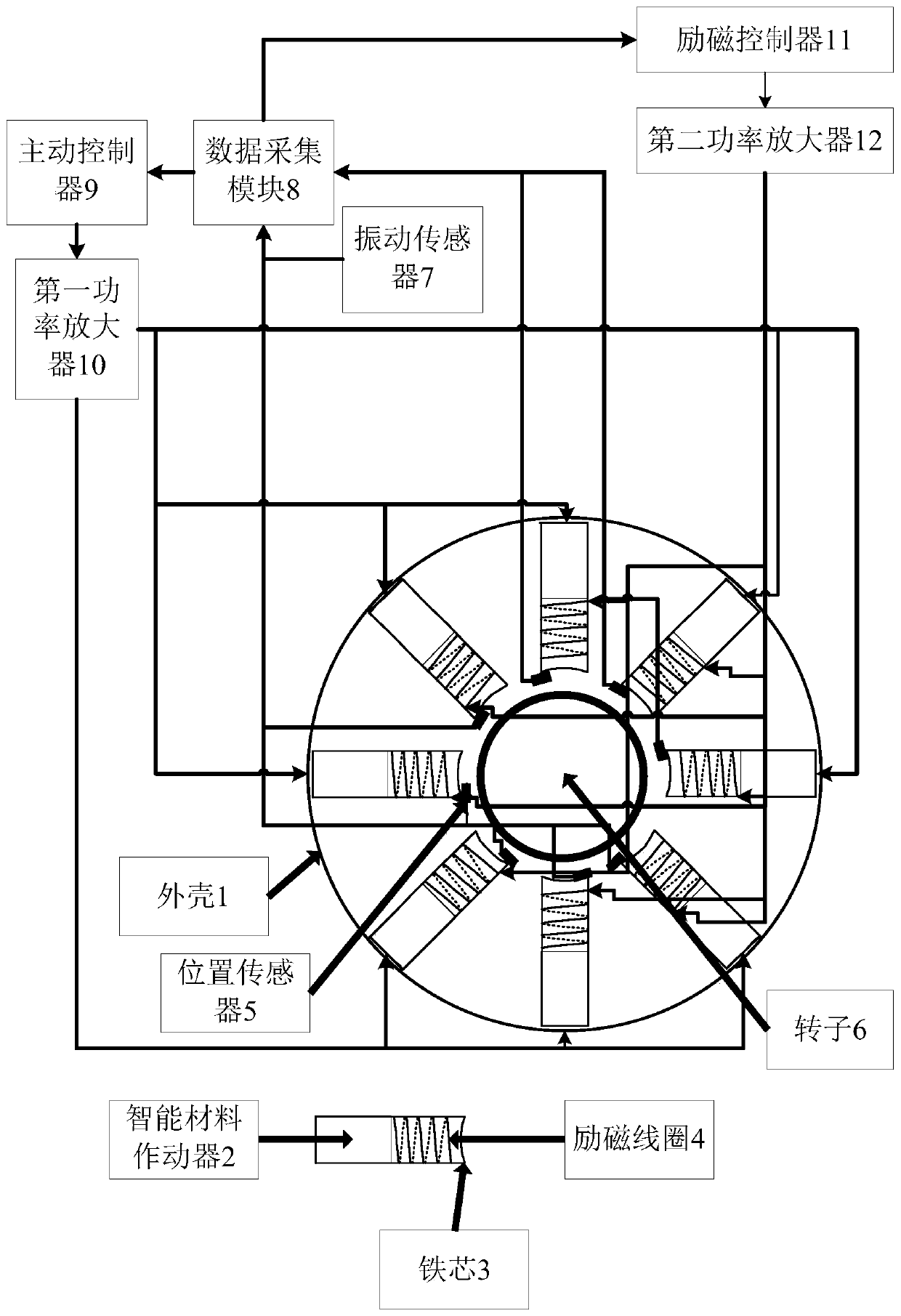

[0020] Aiming at the deficiencies in the prior art, the present invention is based on the magnetic levitation and vibration active control method, uses intelligent materials to improve the position control method of the magnetic bearing, improves the position control accuracy, and controls the radial vibration of the shafting system at the same time. figure 1 It is a schematic diagram of an active magnetic bearing system based on smart materials that can control the radial vibration of the shaft system provided by an embodiment of the present invention, as shown in figure 1 As shown, the system may include: a housing 1, an intelligent material actuator 2, an iron core 3, an excitation coil 4, a position sensor 5, a rotor 6, a vibration sensor 7, a signal acquisition module 8, an active controller 9, a first power Amplifier 10, excitation con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com