Verticality adjusting device for latticed column construction and using method

A lattice column and vertical adjustment technology, which is applied in the direction of infrastructure engineering, building construction, and building material processing, can solve the problems of inability to adjust the verticality of lattice columns accurately, so as to ensure one-time construction quality and reduce construction cost. Cost, the effect of improving position control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a vertical adjustment device for lattice column construction;

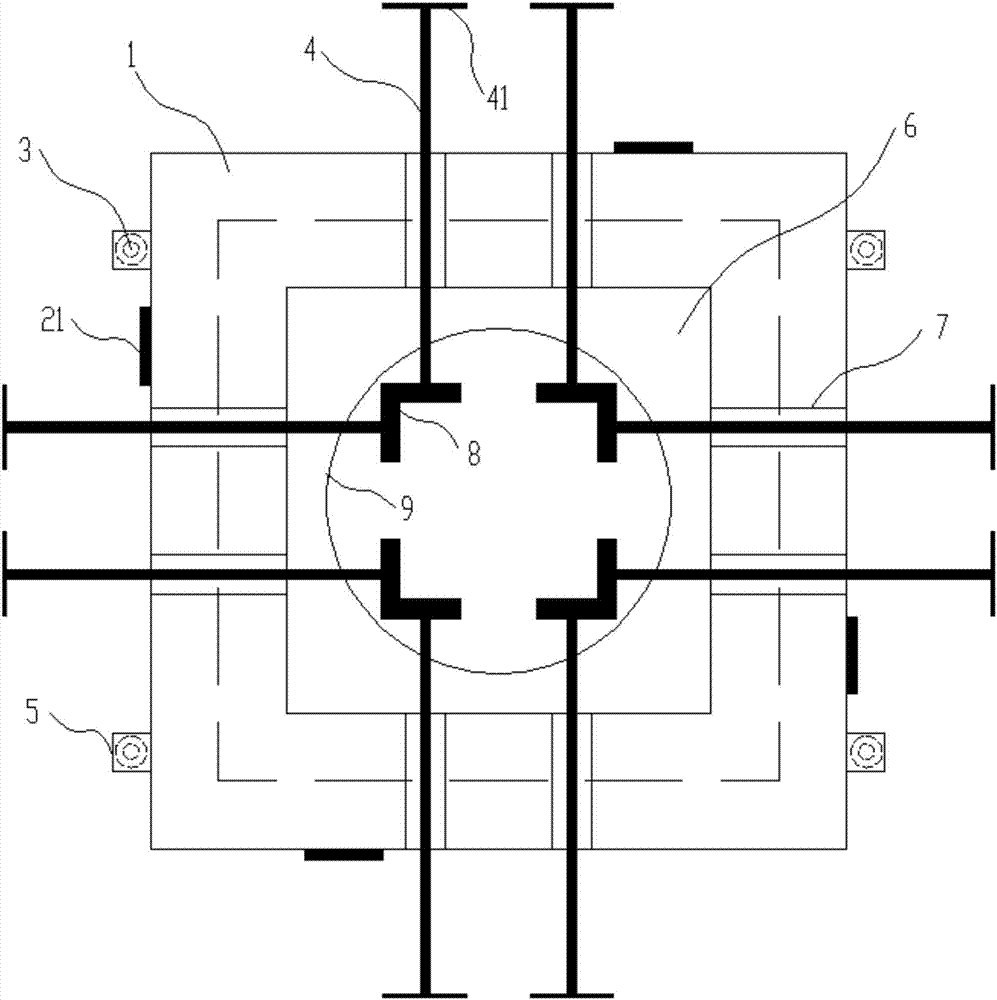

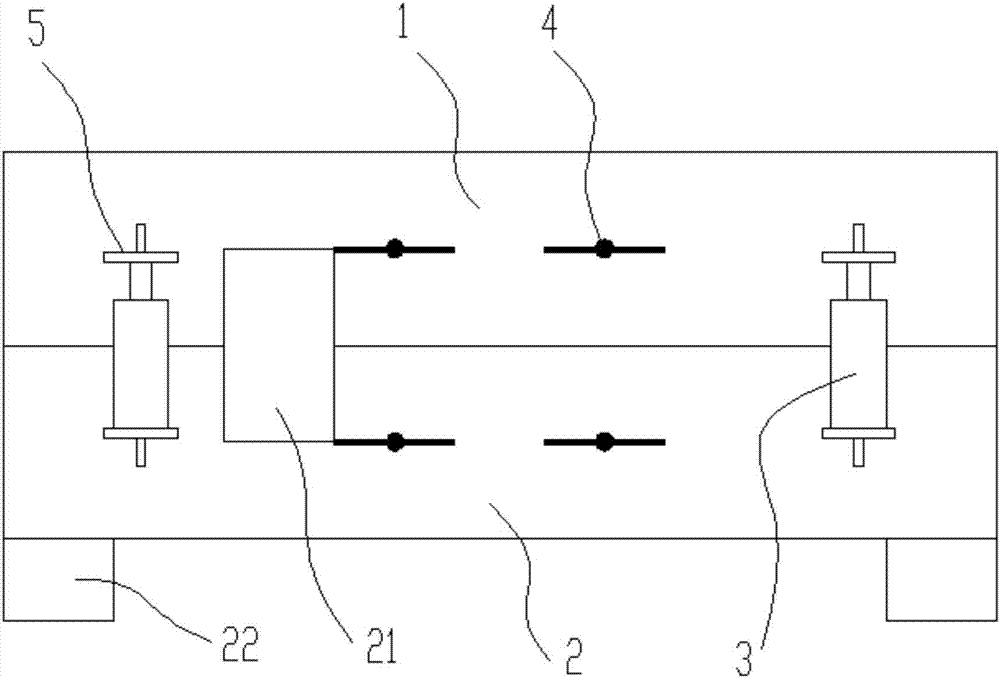

[0039] Such as figure 1 and figure 2 As shown, the vertical adjustment device for lattice column construction in this embodiment includes an upper platform 1 and a lower platform 2 stacked on each other and a plurality of screw rods 4 respectively arranged on the upper platform and the lower platform. The screw rods are located in the same plane and evenly distributed around the platform. The upper platform 1 and the center of the lower platform 2 are provided with a hanging hole 6 for placing the lattice column 8, and its size can add 20mm to the diameter of the steel cage 9, It is convenient for the steel cage 9 and the lattice column 8 to be lowered. If the length of the equilateral angle steel of the lattice column is greater than 20cm, the side length of the lowering hole should be the actual diameter of the reinforcement cage plus the length of the equilateral angle steel. ...

Embodiment 2

[0050] This embodiment provides a method for using a vertical adjustment device for lattice column construction;

[0051] Such as figure 1 and figure 2 As shown, the method for using the vertical adjustment device for lattice column construction in this embodiment includes the following steps:

[0052] a. Lift the upper platform 1 and the lower platform 2;

[0053] b. Adjust the levelness of the upper platform 1;

[0054] c. Surveyors measure and place the guard pile points to the top of the upper platform, and make corresponding marks;

[0055] d. Use a crane to lift, and lower the lattice column to the design elevation position and use I-beams for shelving;

[0056] e. Adjust the verticality of the lattice column.

[0057] In this embodiment, in step a, before the platform is placed, the placement position of the lower platform 2 should be processed in advance, and sleeper pads or prefabricated reinforced concrete slabs can be used to place it, and the reinforcement ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com