Integral probe card and assembling mode

A probe card and probe technology, applied in the field of probe cards, can solve problems such as affecting test stability, small probe deformation ability, and easy signal error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] see Figure 1 to Figure 1 1. An integrated probe card (100), which provides a preferred embodiment of the present invention, mainly includes a plurality of predetermined number of probes (10), a circuit space converter (20), and a flexible circuit communication connection board (30), a circuit board (40) and a level adjustment mechanism (50), wherein:

[0042] These probes (10) are made by following steps:

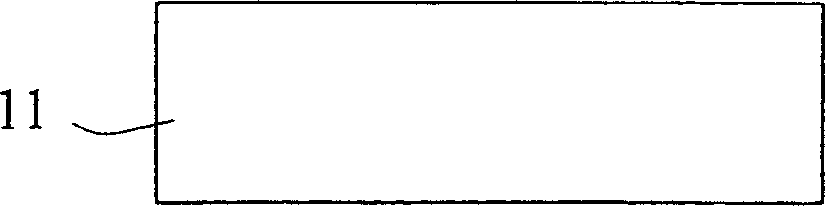

[0043] Step 1. Prepare the base material: figure 1 As shown, take a sheet-like wafer substrate (11) (note: it is a side section shown in the figure), and complete necessary pre-treatments such as cleaning and drying (the substrate used in this embodiment ( 11) is a silicon wafer).

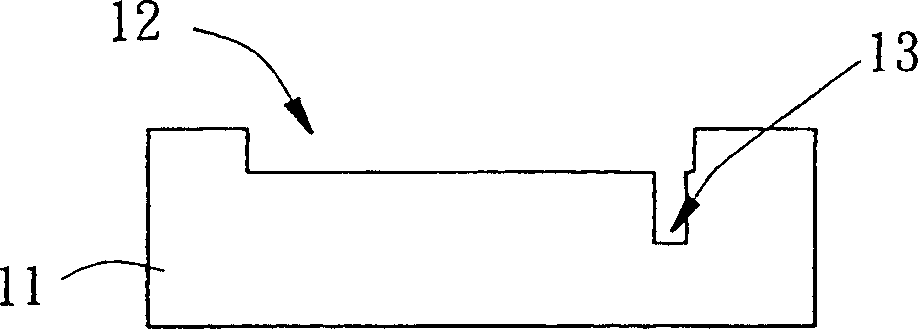

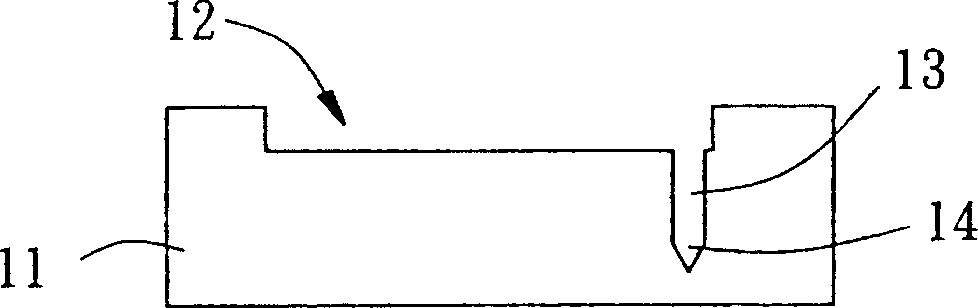

[0044] Step 2. Etching recesses on the substrate: if figure 2 As shown, the geometric shape and position of the probe tip (Probe tip) are precisely defined by using the lithography process (Lithography Process; LIGA), and then the anisotropic etching (anisotropicetching) is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com