Magnetostriction coefficient measuring device and measuring method

A magnetostrictive coefficient and measuring device technology, which is applied in the direction of magnetostrictive performance measurement, measuring device, magnetic performance measurement, etc., can solve the problem of low efficiency, large deviation in the measurement reproducibility of magnetostrictive measuring instruments, and failure to meet the accuracy requirements, etc. problems, to achieve high-efficiency results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings, specific embodiments and comparative examples, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

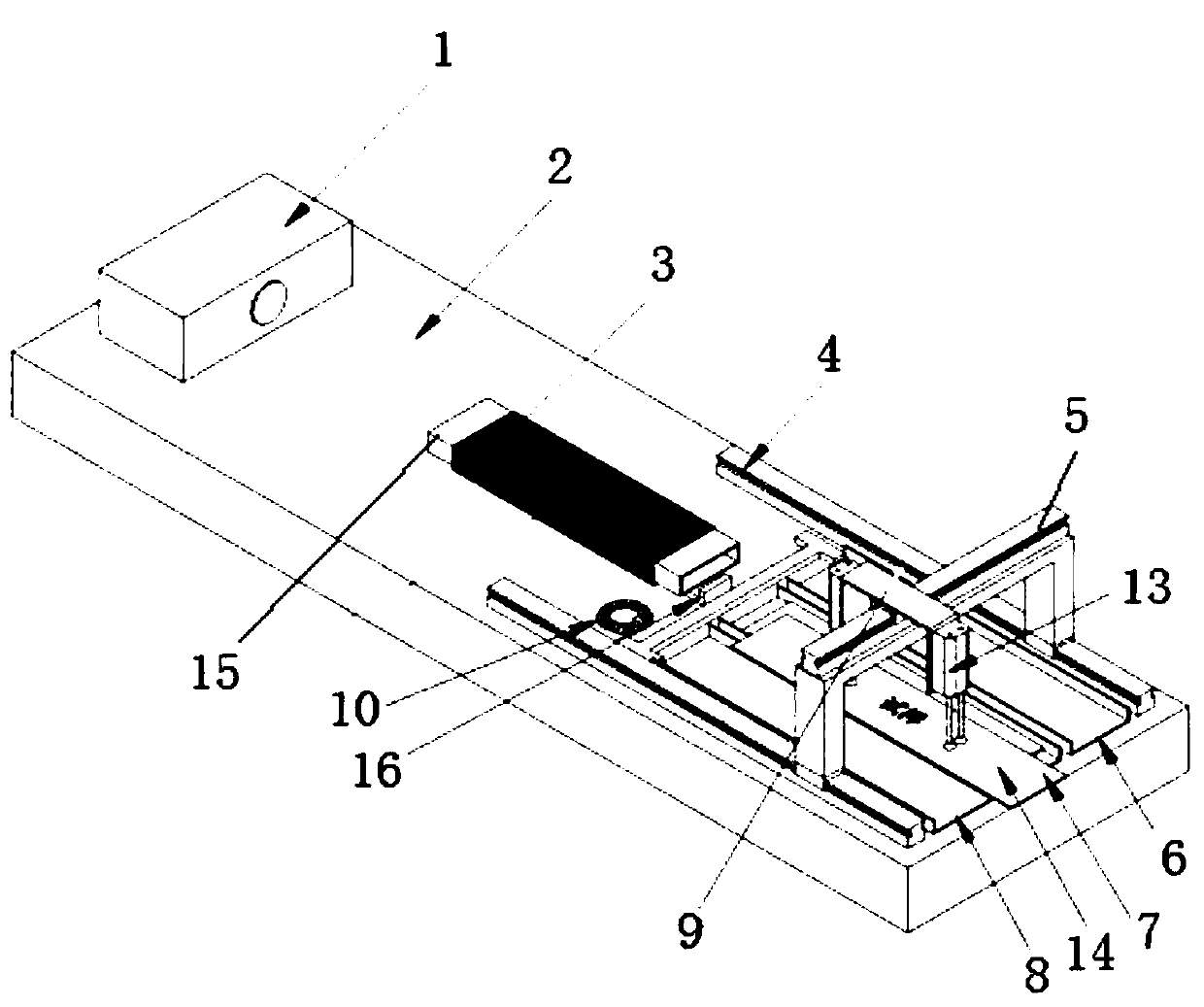

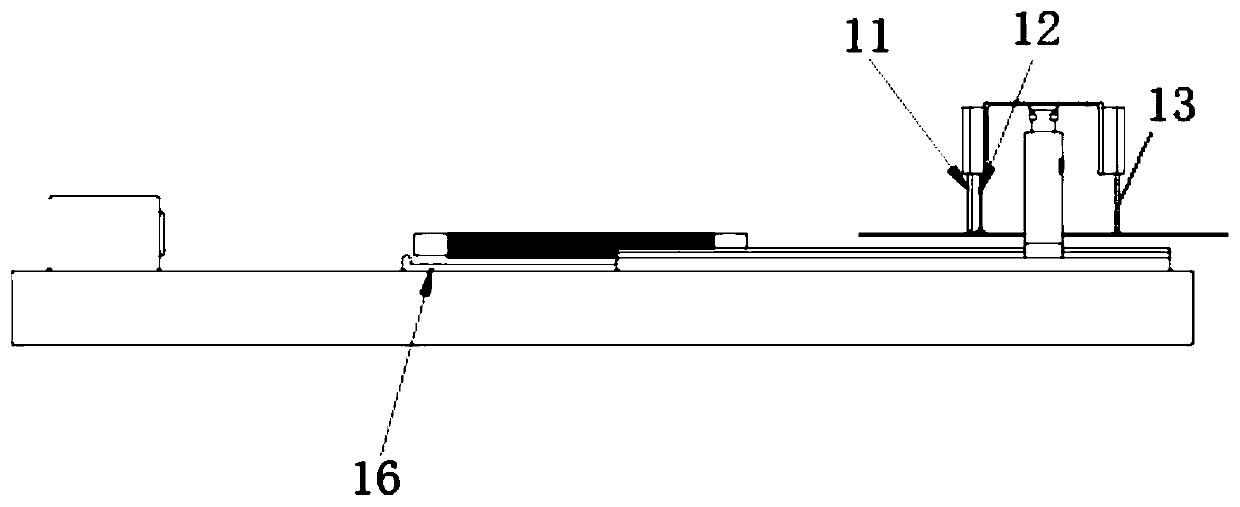

[0027] like figure 1 , figure 2 The measuring device for the magnetostriction coefficient shown includes an air-floating platform 2, a laser vibrometer 1, an excitation unit 3, a self-adhesive unit for reflective sheets, a sliding unit and a sampling unit that are all arranged on the upper surface of the air-floating platform 2, wherein the laser The vibrometer 1 is located on one side of the upper surface of the air-floating platform 2, the sliding unit is located on the other side of the upper surface of the air-floating platform 2, and the excitation unit 3 is arranged on the upper surface of the air-floating platform 2 and is located between the laser vibrometer 1 and the sliding unit. between....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com