Coating for guide rail surface of mineral castings, method for its preparation and guide rail surface having same

A technology of mineral castings and guide rail surfaces, which is applied to the surface coating liquid device, epoxy resin coating, coating, etc., can solve the problems of time-consuming, labor-intensive, wear-resistant, and insufficient rigidity of the guide rail surface, and achieve The preparation method is simple and easy, the plane precision is high, and the effect of saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

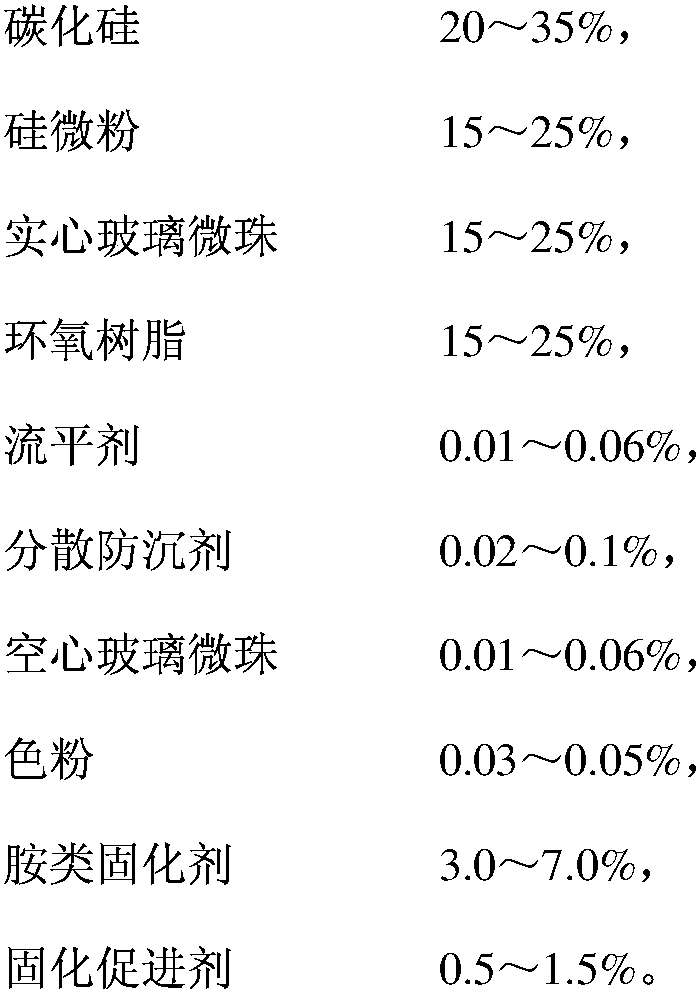

[0034] The preparation method of the mineral casting guide rail surface coating provided by the invention comprises the following steps: (1) mixing epoxy resin, leveling agent, dispersing anti-settling agent, hollow glass microspheres and toner, and stirring to obtain mixture A; ( 2) Add amine curing agent and curing accelerator to the mixture A obtained in step (1), and stir to obtain mixture B; (3) add silicon carbide, silicon micropowder, solid glass micropowder to the mixture B obtained in step (2) Beads, stirred to get mineral casting guide rail surface coating. The preparation method of the above-mentioned coating for the guide rail surface of the mineral casting is simple and feasible, and the raw materials are also easy to obtain.

[0035] The surface of the mineral casting guide rail provided by the present invention includes the above coating for the mineral casting guide rail surface or the coating formed by the coating for the mineral casting guide rail surface pre...

Embodiment 1

[0041]The preferred embodiment of the present invention provides a kind of mineral casting rail surface coating, comprising the following components by weight percentage: 1200 mesh green silicon carbide 29%, 800 mesh silicon micropowder 23%, 120 mesh solid glass microspheres 23% , 18% epoxy resin, 0.04% leveling agent, 0.07% dispersion anti-sedimentation agent, 0.04% hollow glass microspheres, 0.05% toner, polyetheramine 5.5%, aminoethylpiperazine 1.3%.

[0042] A preferred embodiment of the present invention also provides a method for preparing the above-mentioned mineral casting guide rail surface coating, comprising the following steps: (1) mixing epoxy resin, leveling agent, dispersing and anti-settling agent, hollow glass microspheres, and toner , stirring to obtain mixture A; (2) adding polyetheramine and aminoethylpirazine to mixture A obtained in step (1), and stirring to obtain mixture B; (3) adding 1200 Mesh green silicon carbide, 800 mesh silicon micropowder, 120 me...

Embodiment 2

[0044] The preferred embodiment of the present invention provides a kind of coating material for mineral cast rail surface, comprises the following components by weight percentage: 1800 order green silicon carbide 20%, 1200 order silicon micropowder 25%, 150 order solid glass microsphere 25% , 25% epoxy resin, 0.06% leveling agent, 0.03% dispersion anti-settling agent, 0.06% hollow glass microspheres, 0.05% toner, 4.0% aromatic amine, DMP-300.8%.

[0045] A preferred embodiment of the present invention also provides a method for preparing the above-mentioned mineral casting guide rail surface coating, comprising the following steps: (1) mixing epoxy resin, leveling agent, dispersing and anti-settling agent, hollow glass microspheres, and toner , stir to obtain mixture A; (2) add aromatic amine, DMP-30 to the mixture A obtained in step (1), and stir to obtain mixture B; (3) add 1800 mesh green carbonization to the mixture B obtained in step (2) Silicon, 1200-mesh silicon microp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com