Proportional reversing valve for eliminating hysteresis of main valve

A technology of proportional reversing valve and hysteresis, which is applied in the field of hysteresis elimination machine-hydraulic servo system, can solve problems such as hysteresis control accuracy, achieve good stability, good dynamic characteristics, and improve the effect of position control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

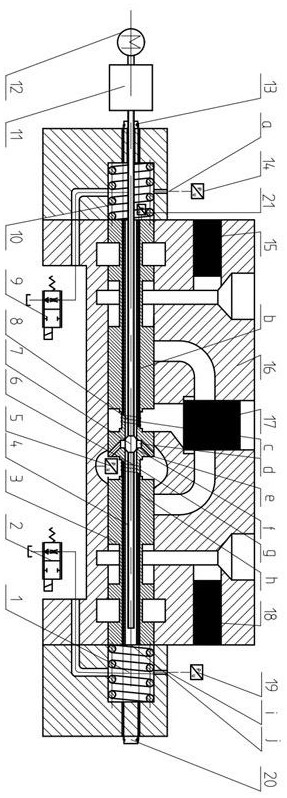

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] see figure 1 , the present invention includes a main valve core 3, a ball screw 4, a servo motor 12, a right-position energized coil 6, a left-position energized coil 8, a left-position pilot oil chamber two-position two-way proportional reversing valve 9, a right-position pilot oil chamber Two-position two-way proportional reversing valve 2, left pilot oil chamber pressure sensor 14, right pilot oil chamber pressure sensor 20, oil inlet pressure sensor 5, main valve right spring 1, main valve left spring 10, pressure Compensator 17, left plug 15, right plug 18, reducer with two reduction ratios 11, left wire power supply 13, right wire power supply 21, pilot spool 7, valve body 16, main spool displacement sensor 15.

[0017] The main valve core 3 is provided with a through hole j on the end surface of the main valve core communicated with the pilot oil chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com