Halbach permanent magnet synchronous servo motor

A servo motor and permanent magnet synchronous technology, which is applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit stationary parts, magnetic circuit rotating parts, etc., can solve the problem of more motor parameter restrictions and increased process manufacturing Difficulty, reduce motor efficiency and other issues, to achieve the effect of cost reduction, performance improvement, and reduction of cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

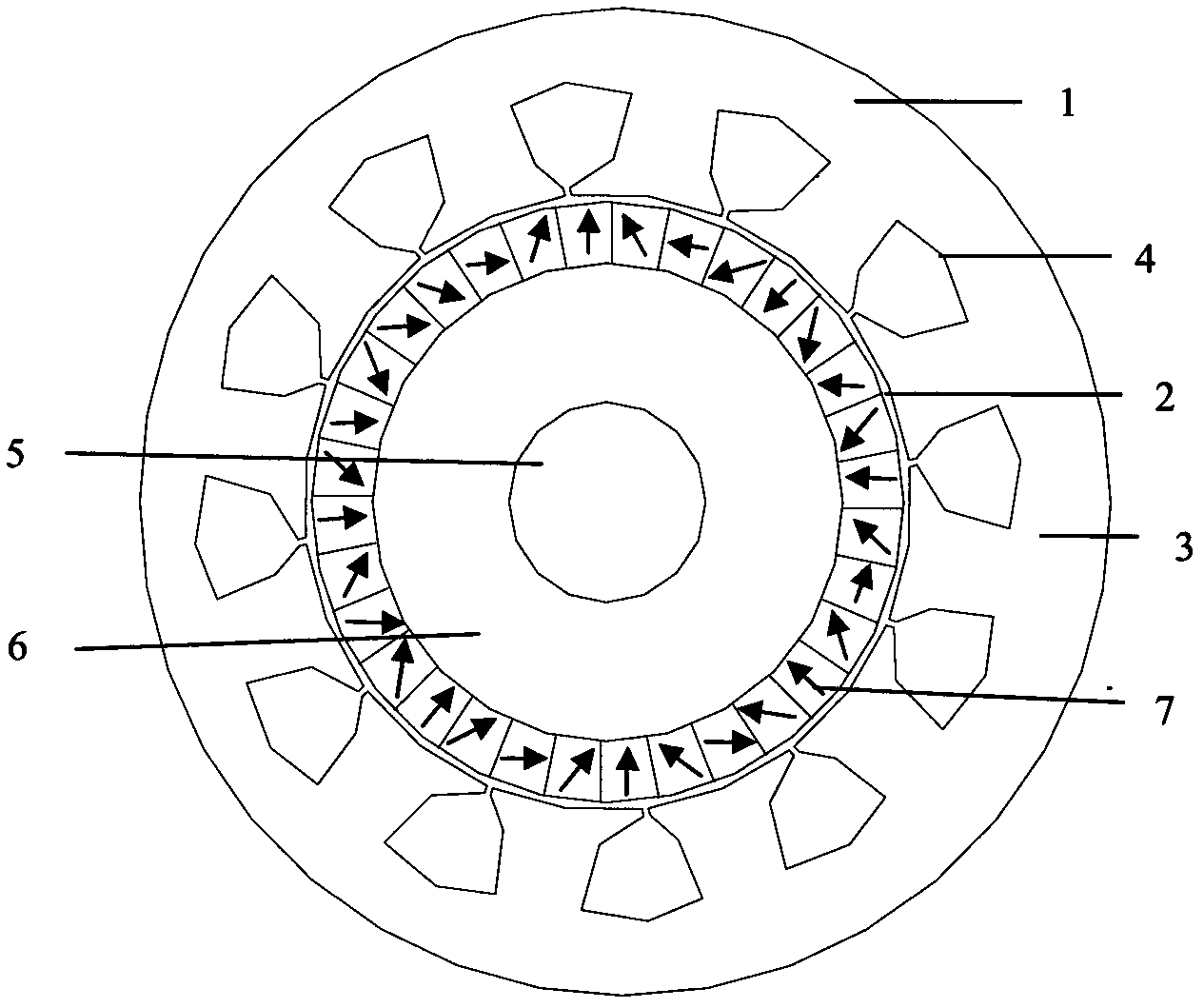

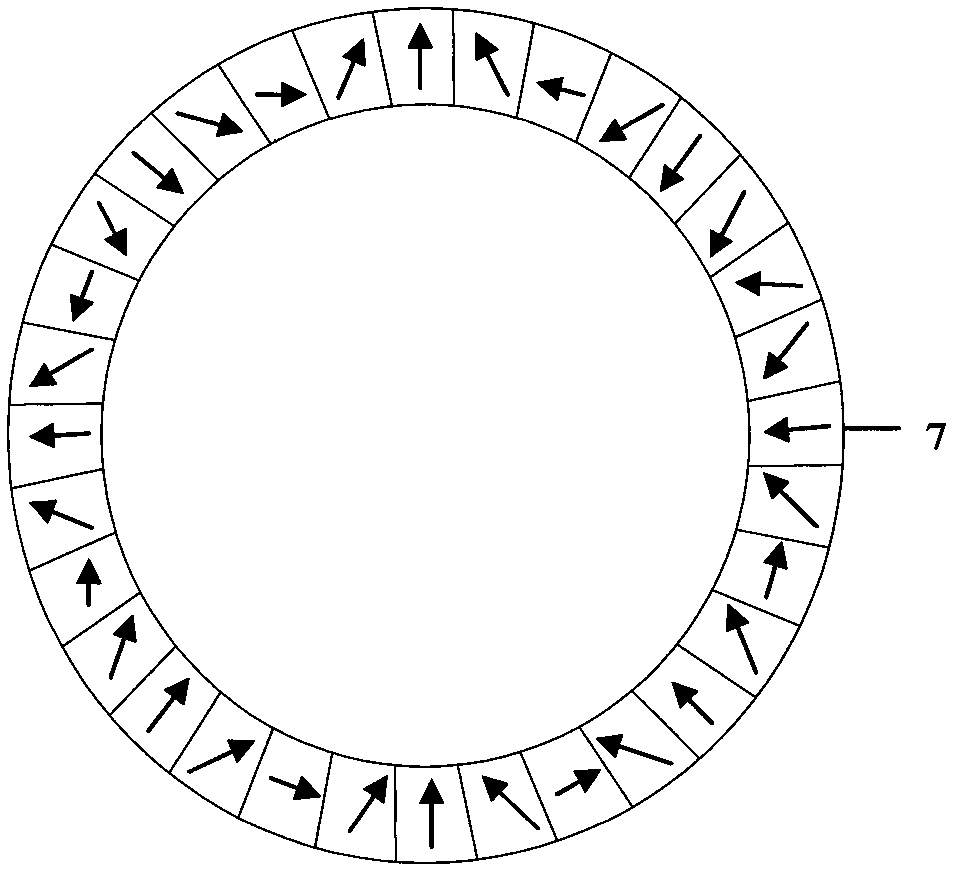

[0013] The invention includes a stator 1, a rotor 2, a stator core 3, a stator slot 4, a rotating shaft 5, a rotor core 6 and a permanent magnet 7 of Halbach structure. The stator core is formed by stacking stator punches, the stator punches adopt an asymmetric groove structure, and the stator is provided with concentrated windings. The rotor core adopts a solid structure, and the permanent magnets forming the rotor adopt a special magnetic circuit structure, that is, a Halbach array structure. In this example, there are 4 anisotropic permanent magnets under each pole, and the number of permanent magnets can be determined according to the actual situation. The design of this magnetic circuit is better than the traditional magnetic circuit design.

[0014] In order to ensure that the motor has a good permanent magnet flux density waveform, in the anisotropic permanent magnet components, the number of anisotropic permanent magnets under each pole should be kept within a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com