Resonator silencer for a radial flow machine, in particular for a radial compressor

A technology of radial flow and compressor, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, noise reduction devices, etc. It can solve problems such as the reduction of sound pressure peaks, and achieve the effects of reduced excitation and low pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

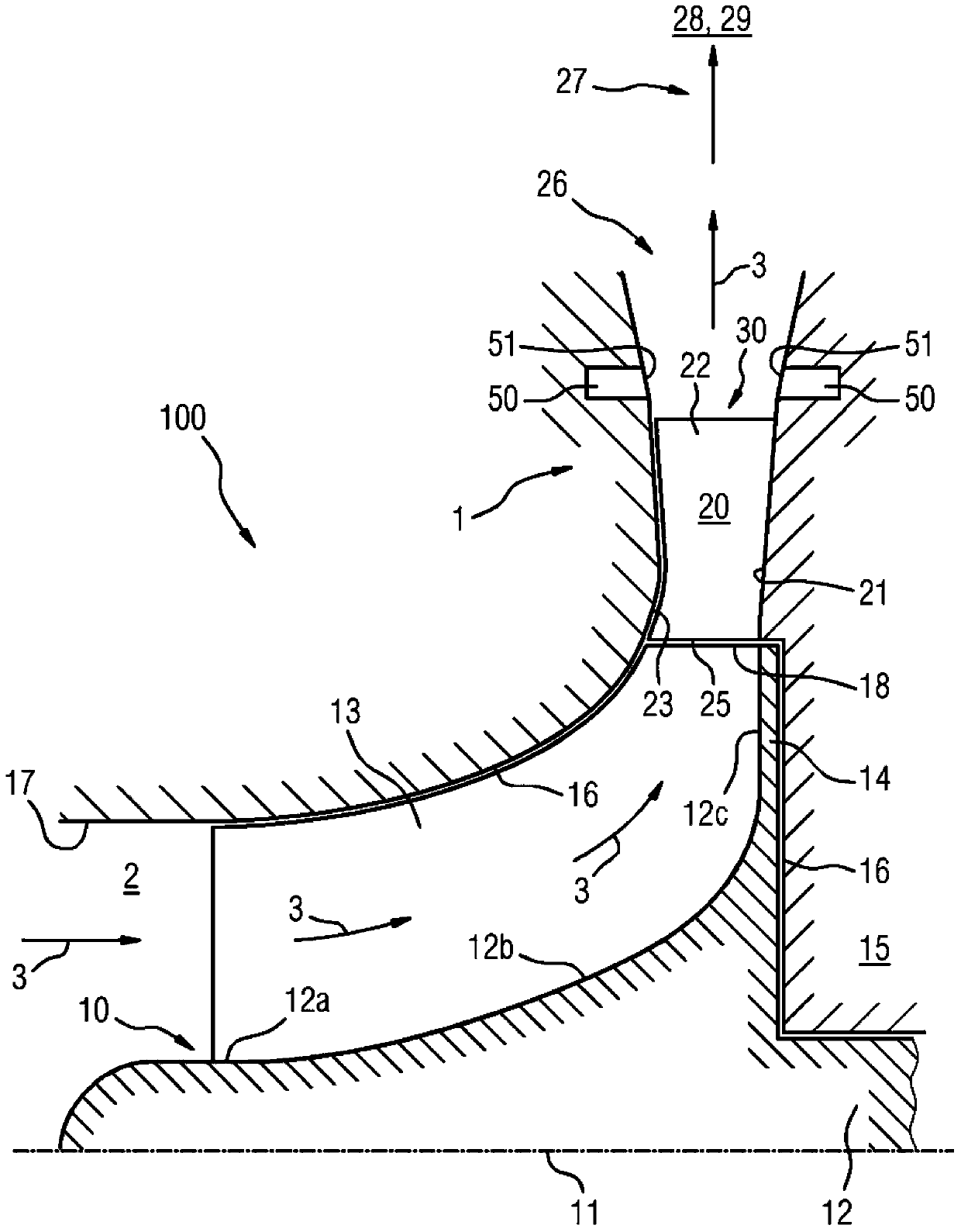

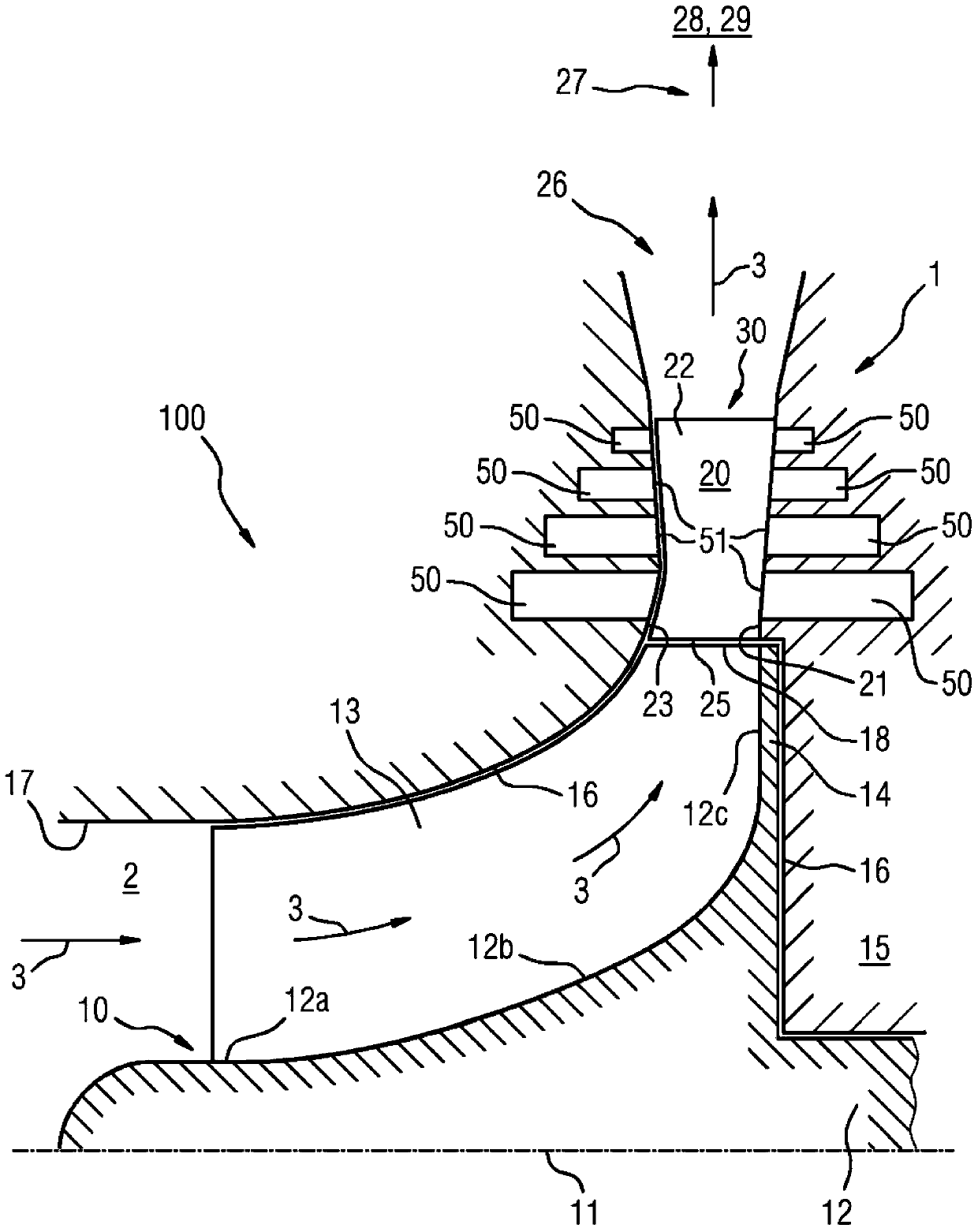

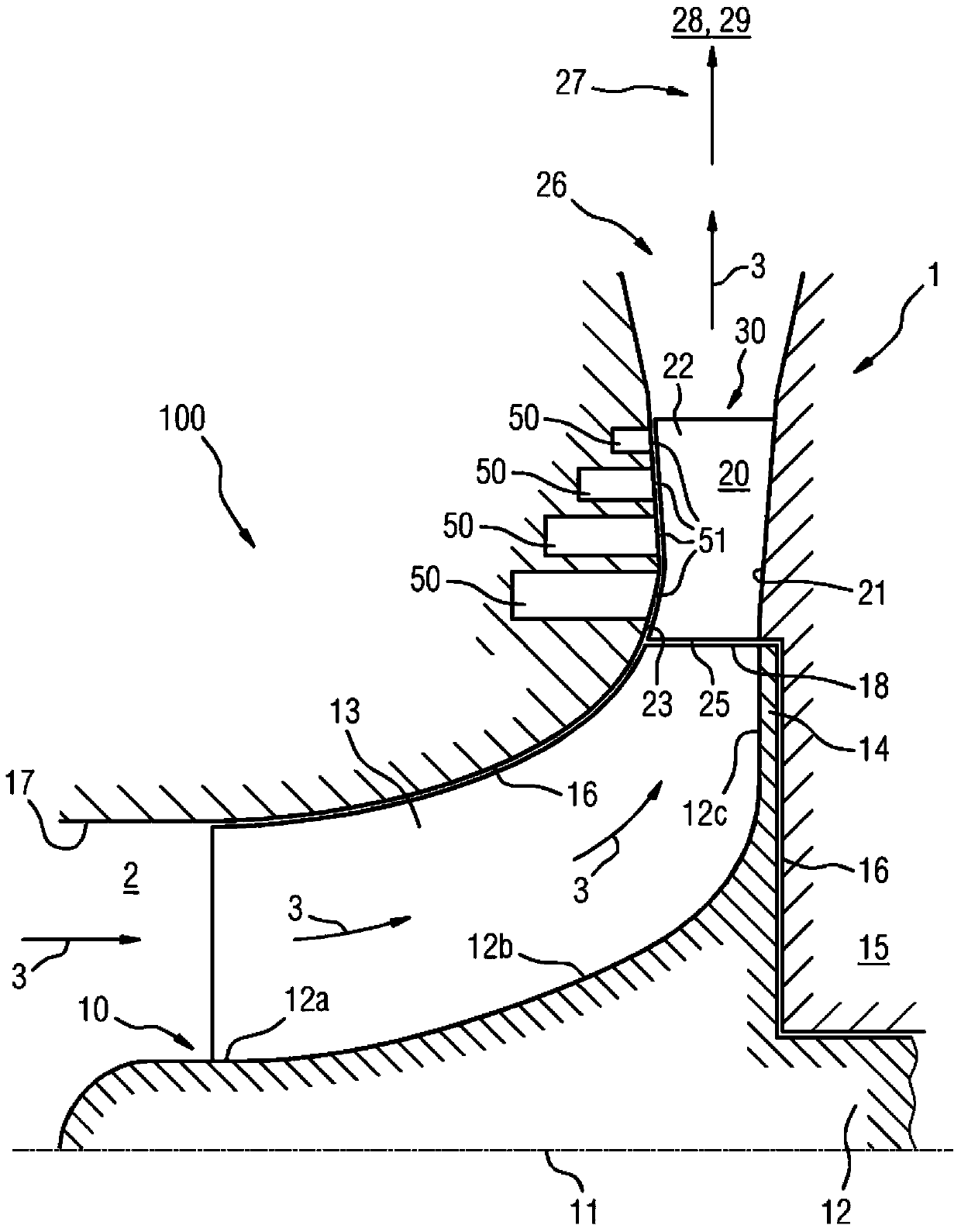

[0065] exist Figures 1 to 3 Different configurations of radial compressors 100 are described in , each with a resonator silencer 1 implemented in the diffuser or integrated in the diffuser.

[0066] Such a radial compressor 100 has, as shown, an impeller 10 which rotates at a high rotational speed about an axis 11 . The impeller 10 has a hub 12 and has blades 13 protruding radially from the hub.

[0067] The hub 12 has a first region 12a, which is substantially cylindrical; a transition region 12b, in which the radius of the hub increases; and an end region 12c, which is substantially perpendicular to the axis 11 Stretch.

[0068] —In Flow Direction 3 —Axially inflowing gas 2 rotates through impeller 10 and leaves impeller 10 in radial flow direction 3 relative to axis 11 and at an obtuse angle relative to axis 11 .

[0069] The blades 13 are fastened to a common back plate 14 of the hub 12 . The impeller 10 is located in a housing 15 whose walls 16 are adapted to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com