Device for accurately correcting polymeric membrane

A technology of polymer film and deviation correction device, which is used in transportation and packaging, winding strips, thin material processing, etc., can solve problems such as uneven tension changes, film materials cannot smoothly enter the processing equipment, and affect the quality of final products. achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

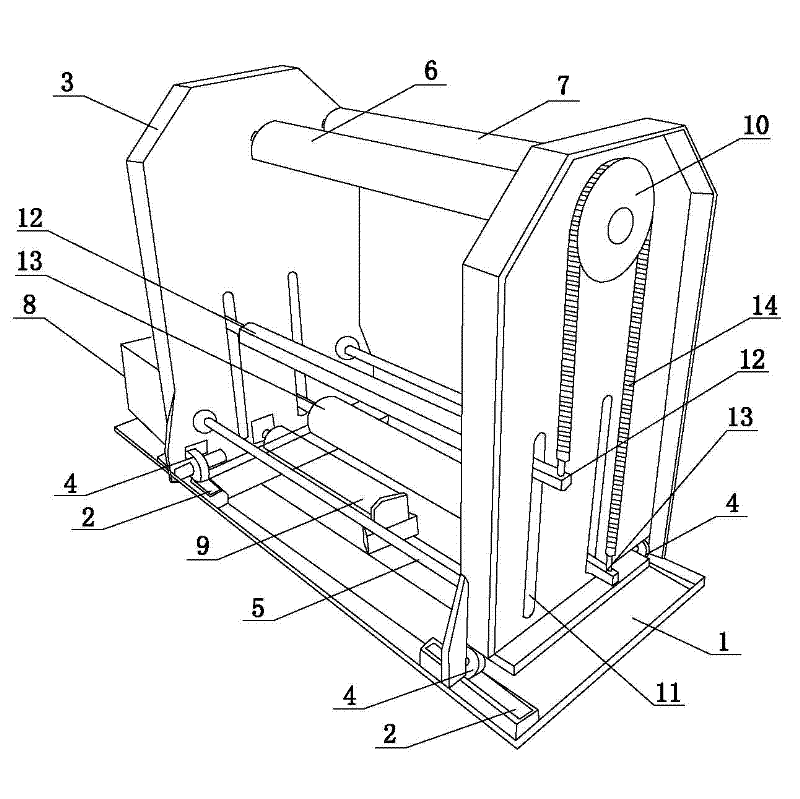

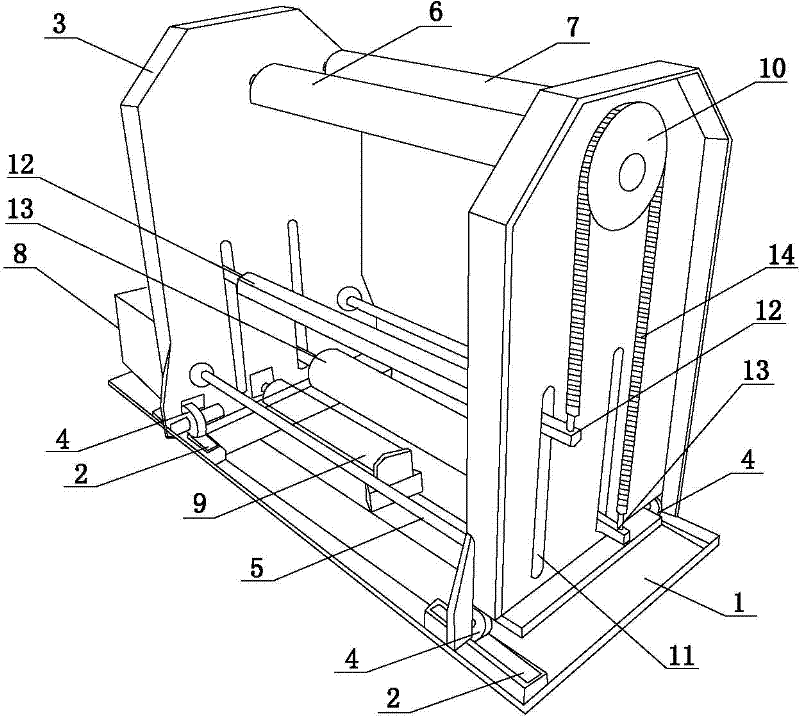

[0014] The structure of the polymer film precise correction device is as follows: figure 1 As shown, the base 1 can be flat or other conventional shapes, and the bottom of the base 1 can be provided with supporting legs or a fixed plate. Four guide rail grooves 2 are arranged on the base 1 . The guide wheel 4 placed on the guide rail groove 2 is located at the bottom of the support frame 3 . The two support frames 3 are fixed by two support columns 5, and the support frames 3 are placed on the base 1 through the guide wheels 4. With the movement of the guide wheels 4, the entire support frame 3 can translate left and right on the base 1.

[0015] At the outlet of the polymer film of the deviation correction device, or at the entrance of the polymer film of the next device, a polymer film swing monitoring device is installed to monitor the lateral disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com