Dry exhaust-gas treating apparatus

A waste gas treatment device, dry technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve problems such as activity reduction, and achieve the effect of ensuring the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, embodiments of the dry exhaust gas treatment device of the present invention will be described with reference to the drawings.

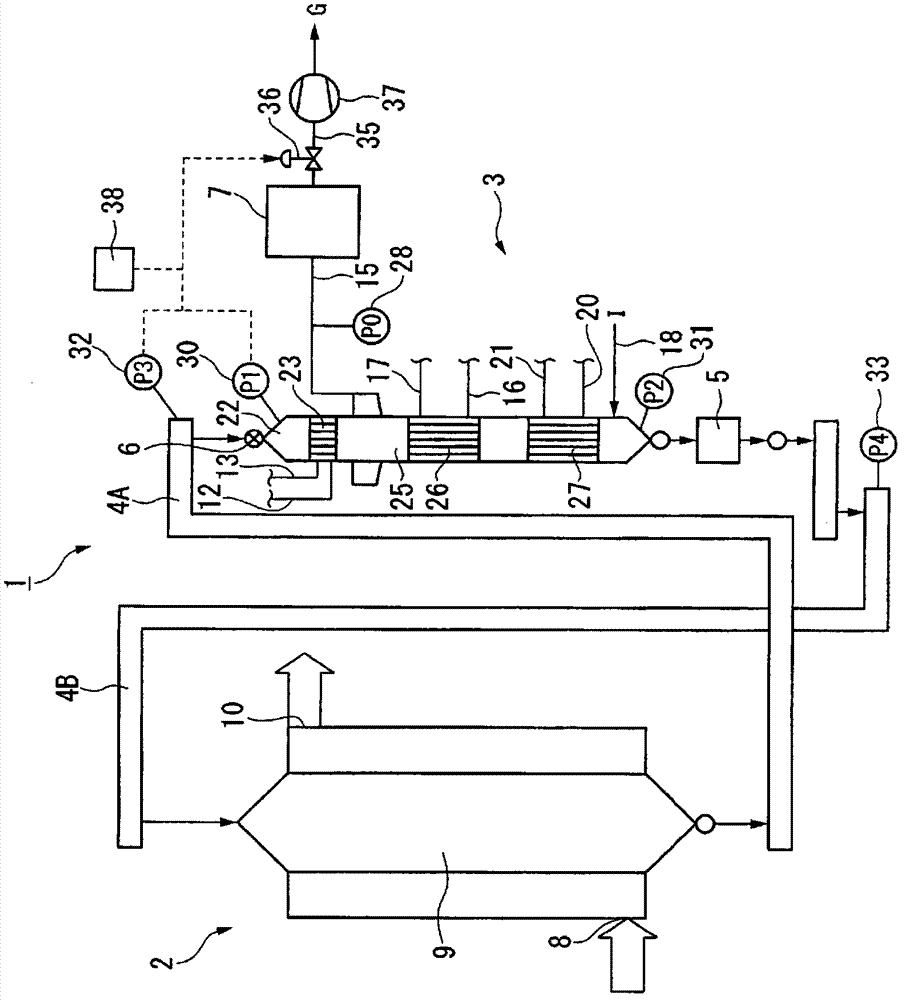

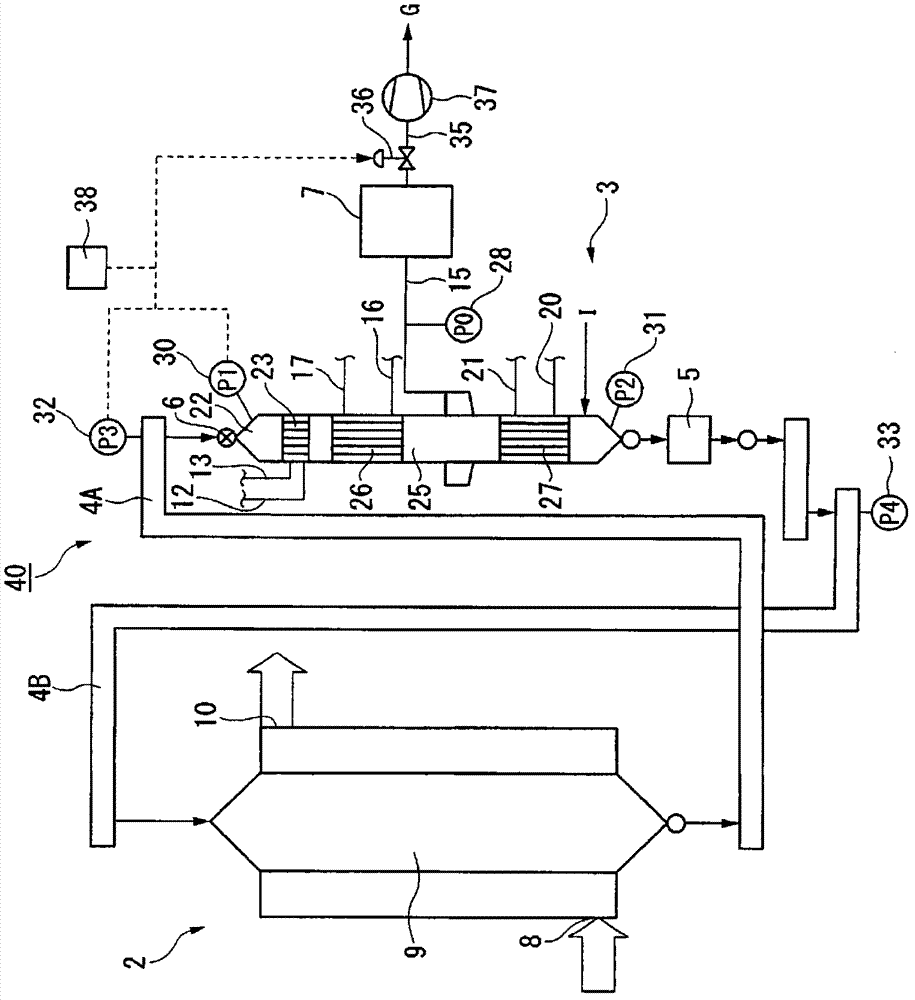

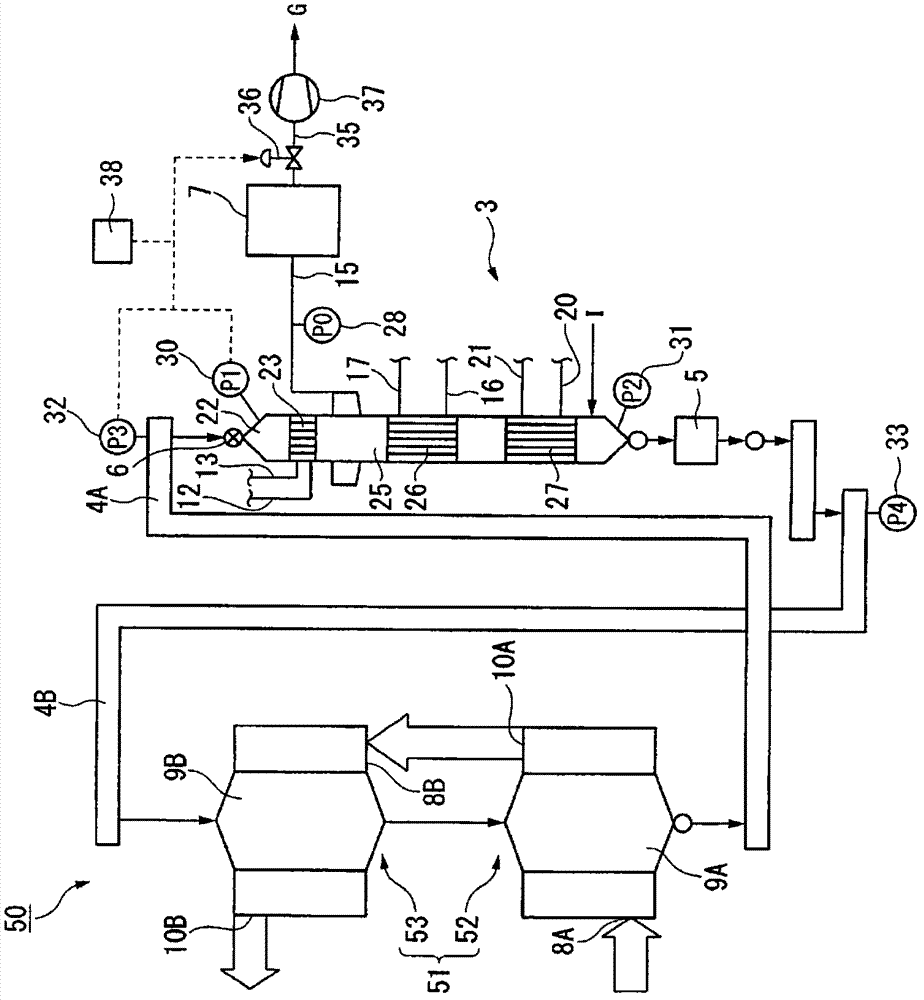

[0037] figure 1 It is a functional block diagram showing the dry exhaust gas treatment device according to the first embodiment of the present invention.

[0038] The dry exhaust gas treatment device 1 of this embodiment has an adsorption tower 2, a regeneration tower 3, a first conveying channel 4A and a second conveying channel 4B that connect the adsorption tower 2 and the regeneration tower 3 and transport the adsorbent, and the lower end side of the regeneration tower 3. The connected lock hopper 5, the rotary valve (sealing part) 6 connected to the upper end side of the regeneration tower 3, and the cleaning tower 7 for cleaning the desorption gas G containing the desorbed product desorbed from the adsorbent.

[0039] The adsorption tower 2 is a device for adsorbing and removing various substances such as SOx (sulfur oxide) in gas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap