Wire harness bracket on automobile

A wire harness bracket and automobile technology, applied to vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of difficult adjustment of the bracket position, low versatility, and non-adjustable fixing holes of wire harness ties, etc., to achieve universal Good performance and convenient position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

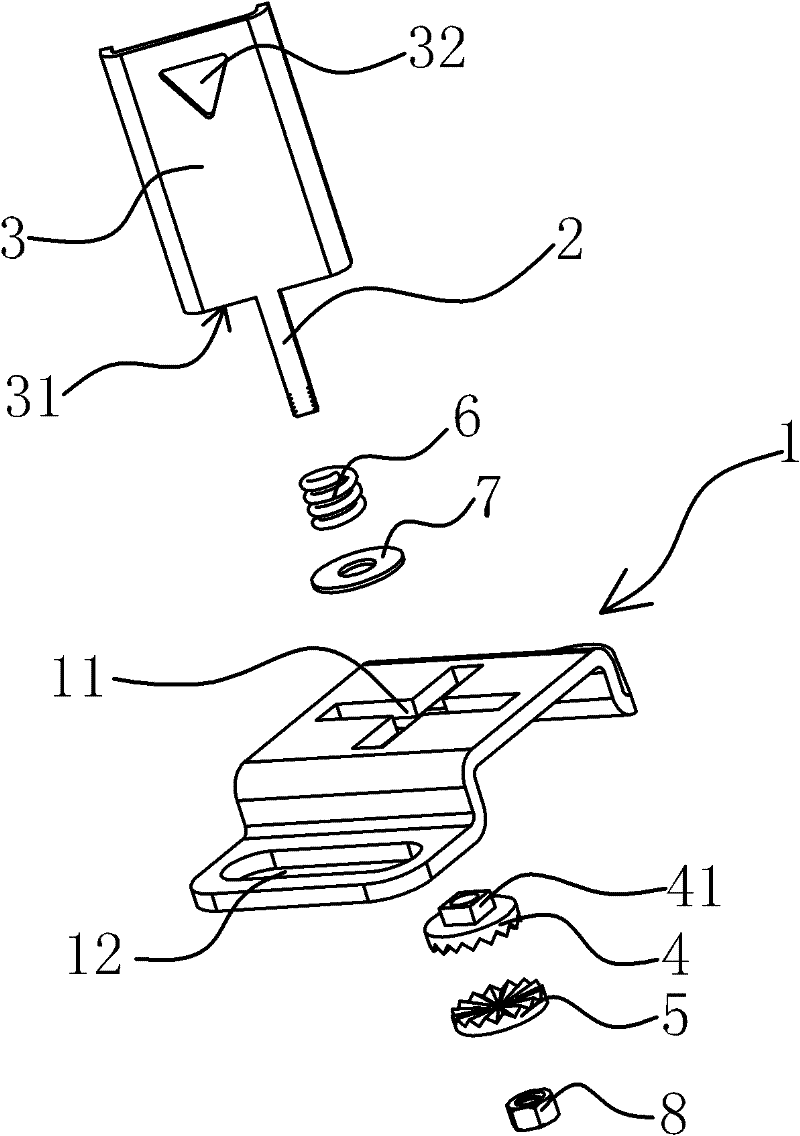

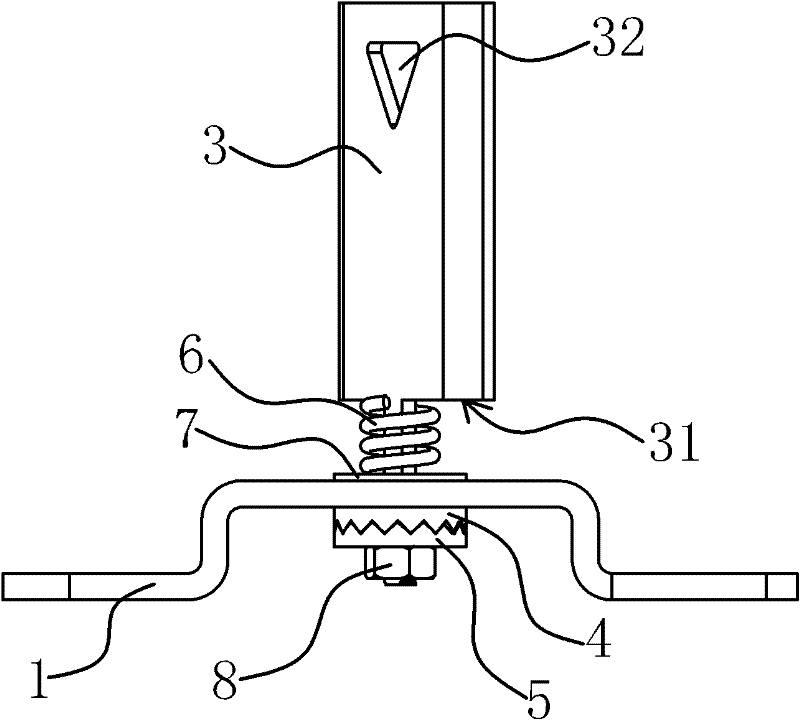

[0033] The wire harness bracket on the automobile includes a base 1, a pole 2, a constraint part 3, a fixing member 8, an adjustment mechanism and an elastic mechanism, and is used to fix the wire harness of electronic equipment in the automobile.

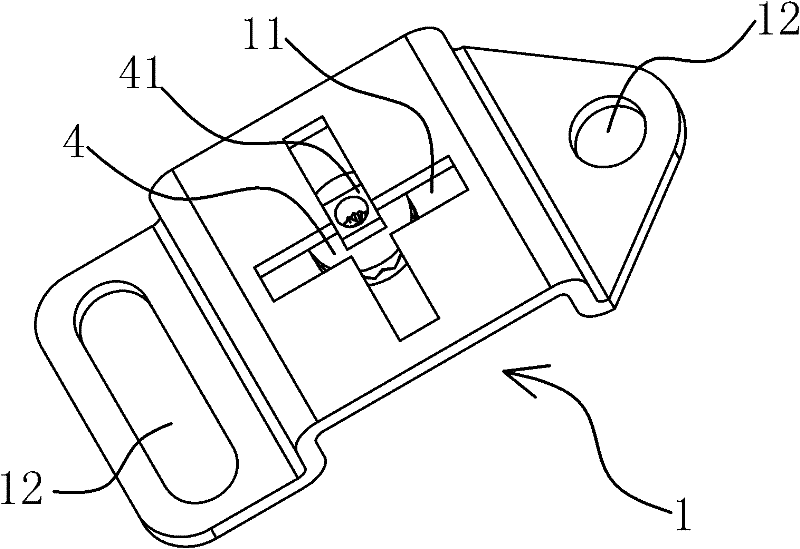

[0034] Such as figure 1 and figure 2 As shown, the base 1 is provided with a cross-shaped chute 11 and two installation holes 12, one of which is a round hole and the other is a strip-shaped hole. The chute 11 is located in the middle of the base 1, and the mounting holes 12 are located on both sides of the chute 11, so that the fixing of the base 1 is more reliable. During installation, the bolt passes through the round hole and is connected to the threaded structure on the car body. Into the threaded structure, the base 1 is fixed on the car body after the bolts are tightened. The above-mentioned threaded structure may be a welded nut or a threaded hole.

[0035] By adjusting the position of the base 1, such a connection str...

Embodiment 2

[0042] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, a radial positioning hole is opened on the pole 2, and the fixing member 8 is capable of passing through the radial positioning hole. The clamping strip on the top, the connection of the pole 2 is reliable, and the production cost can be reduced at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com