Automatic screw twisting machine for photo frame

A screw machine and photo frame technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of wasting time and manpower, uneven product quality and work level, etc., to achieve enhanced assembly efficiency, save manpower, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

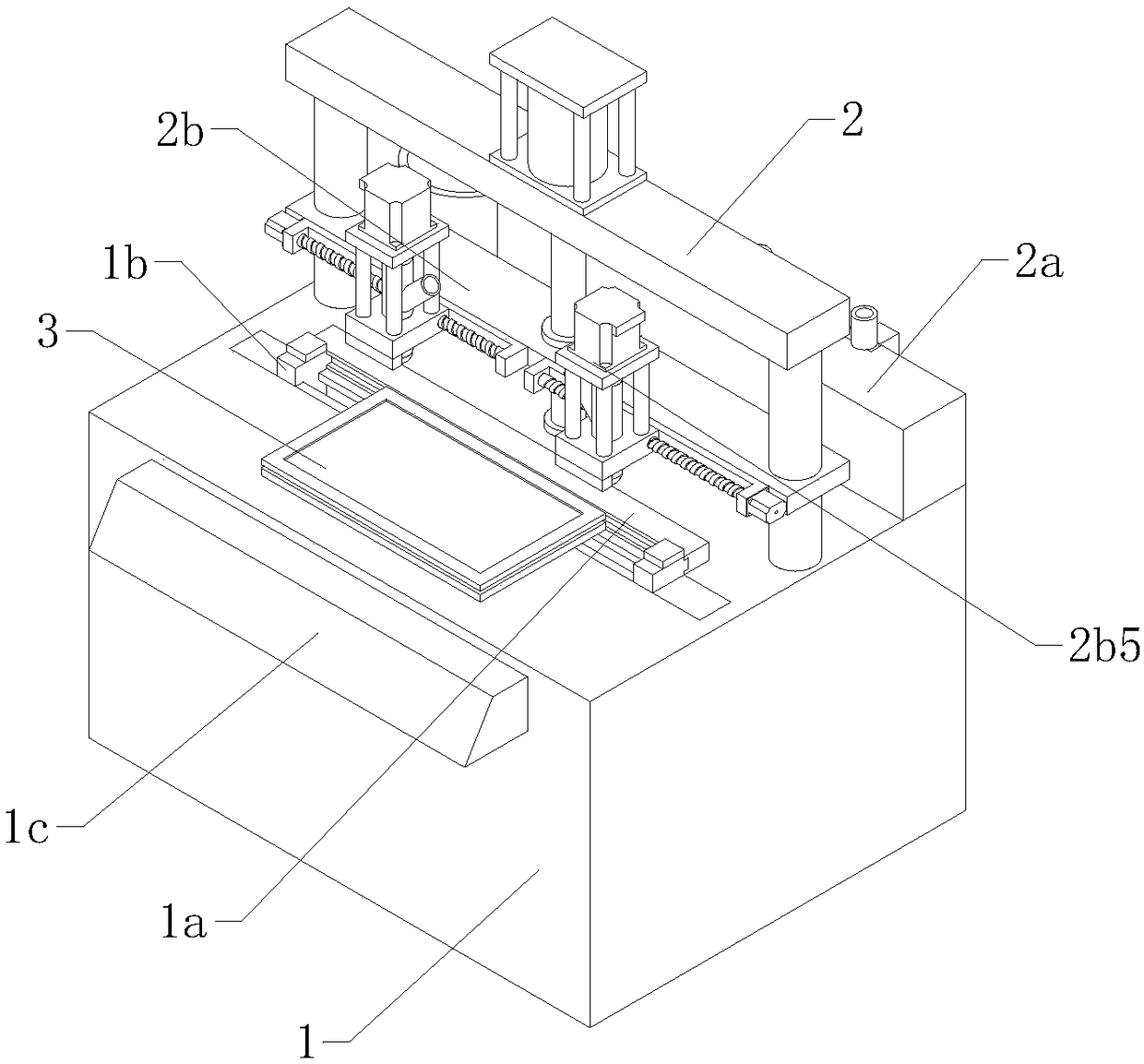

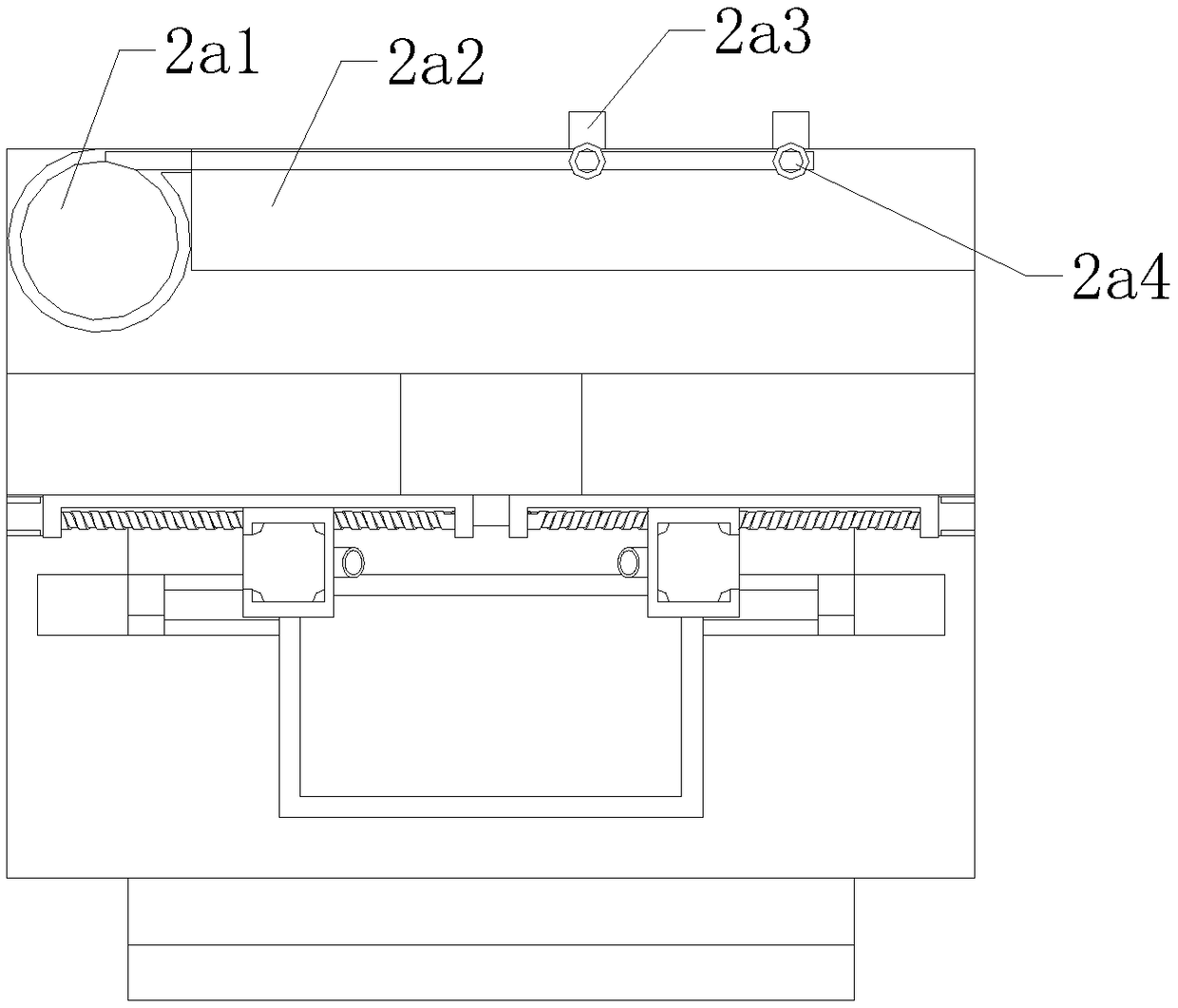

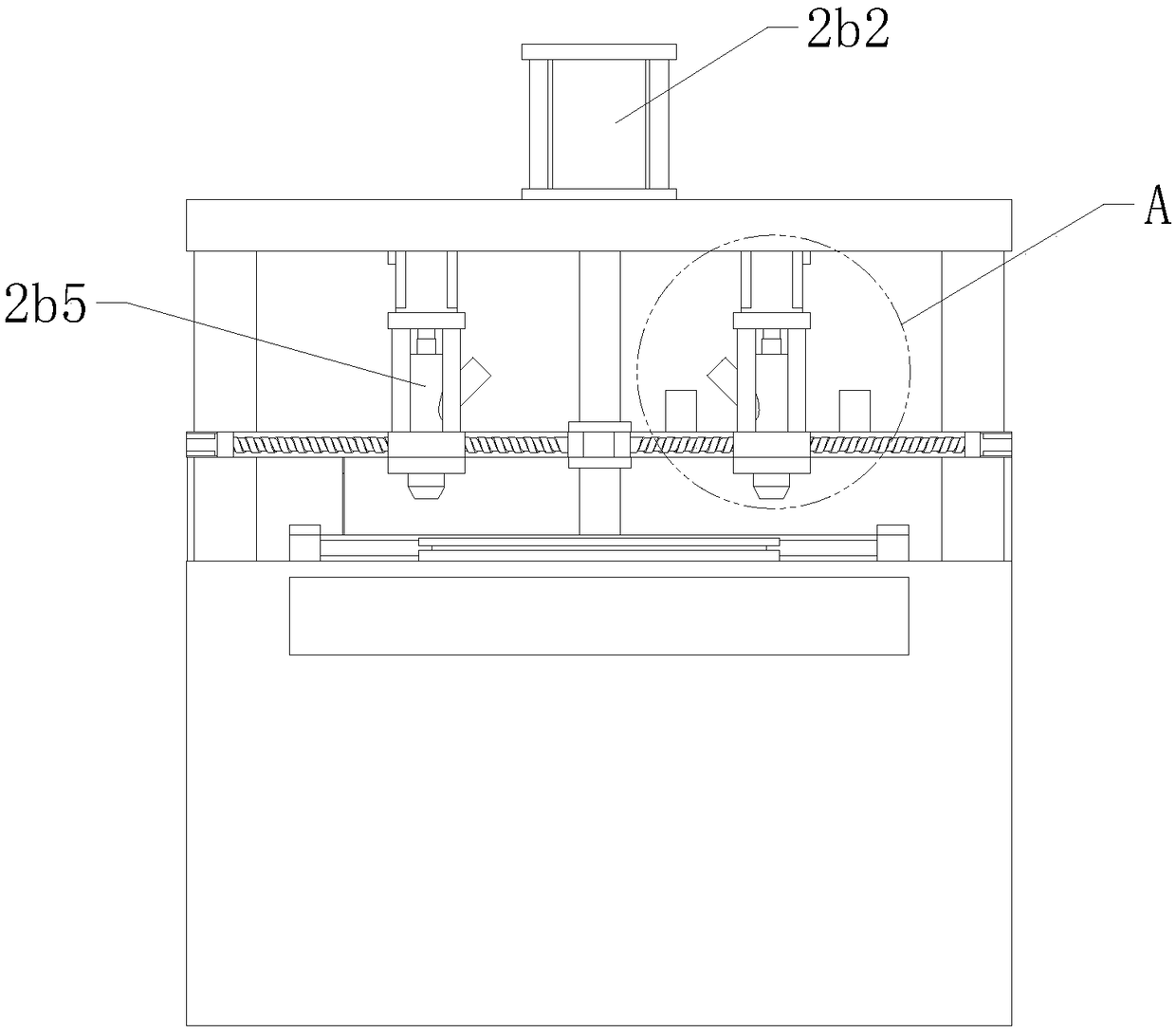

[0027] refer to Figure 1 to Figure 10 An automatic screw-tightening machine for a photo frame is shown, including a workbench 1 and a locking screw device 2, a photo frame fixing jig is arranged above the workbench 1, and the photo frame fixing jig includes a positioning rod 1a and two sets of pneumatic clamps 1b, the positioning rod 1a is located at the middle position above the workbench 1, the pneumatic clamp 1b is set on the workbench 1 and is slidably connected with the positioning rod 1a, and the locking screw device 2 is set on the workbench 1, The locking screw device 2 includes a screw automatic alignment unit 2a and a screw locking unit 2b. The screw automatic alignment unit 2a includes a vibrating disk sorting mechanism 2a1 and a screw storage guide rail 2a2. The vibrating disk sorting mechanism 2a1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com