Plastic-shell locking seal

A technology of sealing and plastic casing, which is applied in the direction of seals, stamps, instruments, etc., to achieve the effects of automation, improved work efficiency, and good security and anti-tampering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

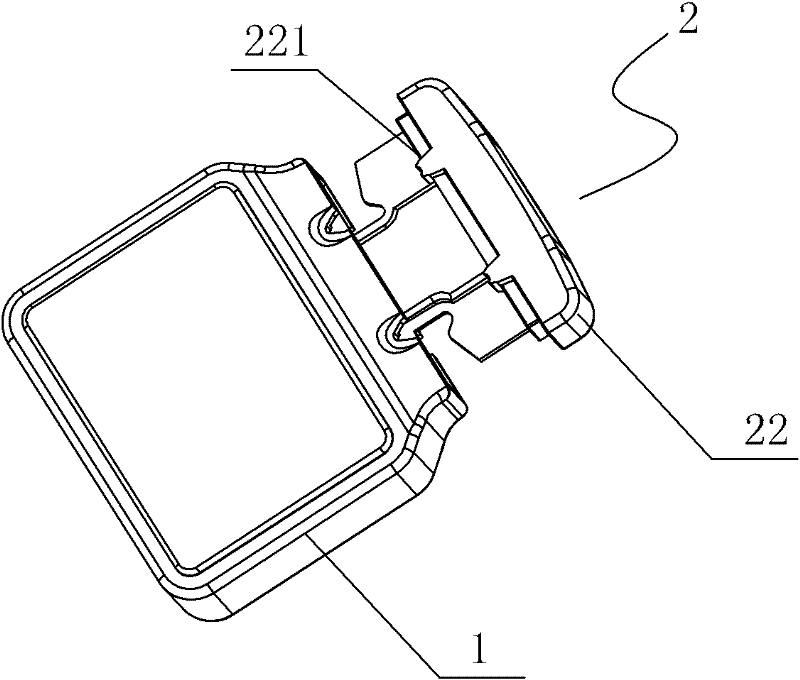

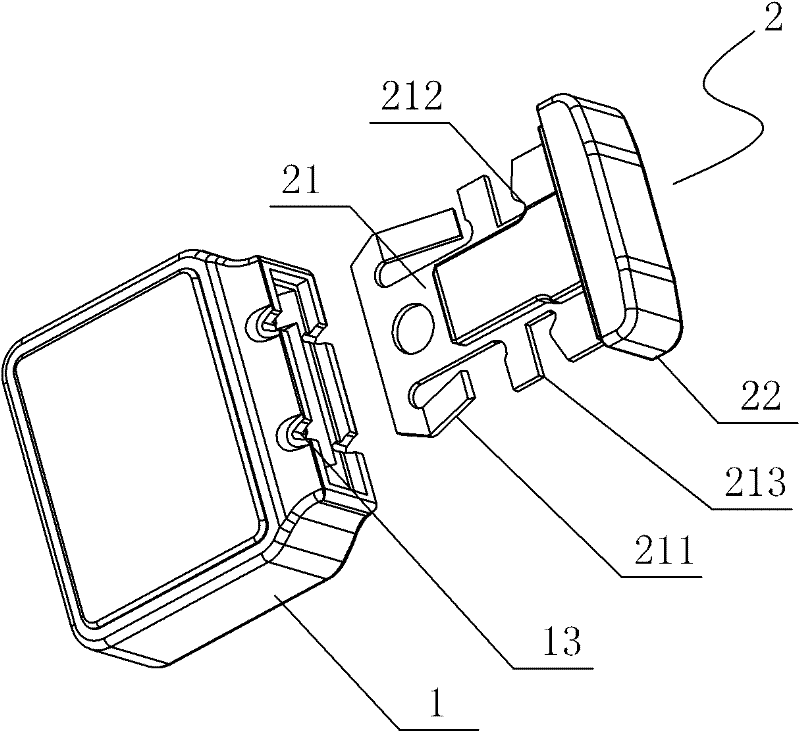

[0028] Such as figure 1 , figure 2 , Figure 4 As shown, the molded case lock of the present invention includes a lock housing 1 and an insert 2 mated with the lock housing 1. The insert 2 includes an elastic chip 21 and a The plug connector 22 placed outside the sealing shell, the elastic chip 21 is provided with two elastic barbs 211 inclined in opposite directions. To improve the convenience of operation; the elastic chip 21 is provided with a card slot 212 for accommodating the sealing wire, and in addition, a threading slot is provided at the end surface of the sealing housing 1 and the plug connector 22 where it fits.

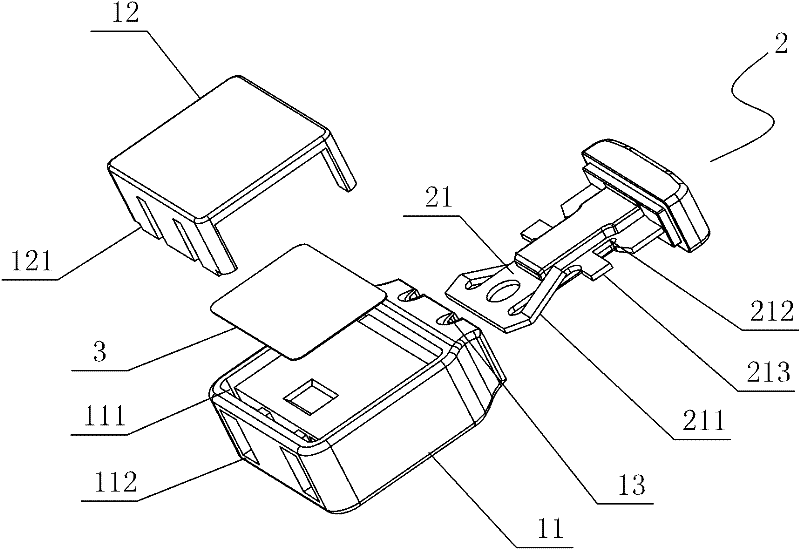

[0029] Such as image 3 As shown, the sealing housing 1 includes a body 11 and a cover 12 mated with the body 11. The bottom of the cover 12 is provided with an insertion column 121, and the body 11 is provided with a socket for accommodating the insertion of the insertion column 121. In addition, the bottom of the body 11 is provided with a process ...

Embodiment 2

[0037] This embodiment is basically the same as the first embodiment above, the difference is: Figure 6 , Figure 7 As shown, the threading groove includes a first groove 16 placed in the sealing housing 1 and a second groove 222 placed in the plug connector 22, the first groove 16 and the second groove 222 are combined to form Threading trough, the effect of this threading trough is exactly the same as embodiment one, repeats it no longer here.

Embodiment 3

[0039] This embodiment is basically the same as the first and second embodiments above, the difference is that: Figure 8 As shown, the threading groove is a plug connector groove 223 placed on the plug connector 22 where it cooperates with the sealing housing 1. The function of the plug connector groove 223 is the same as that of the previous embodiments, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com